Alkalis excited inorganic gel mortar interlining composite pipes

An inorganic gelling and alkali-activated technology, applied to pipes, rigid pipes, mechanical equipment, etc., can solve the problems of high cost and easy leakage of the pipe body, achieve good bending strength, reduce product cost, and reduce thickness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

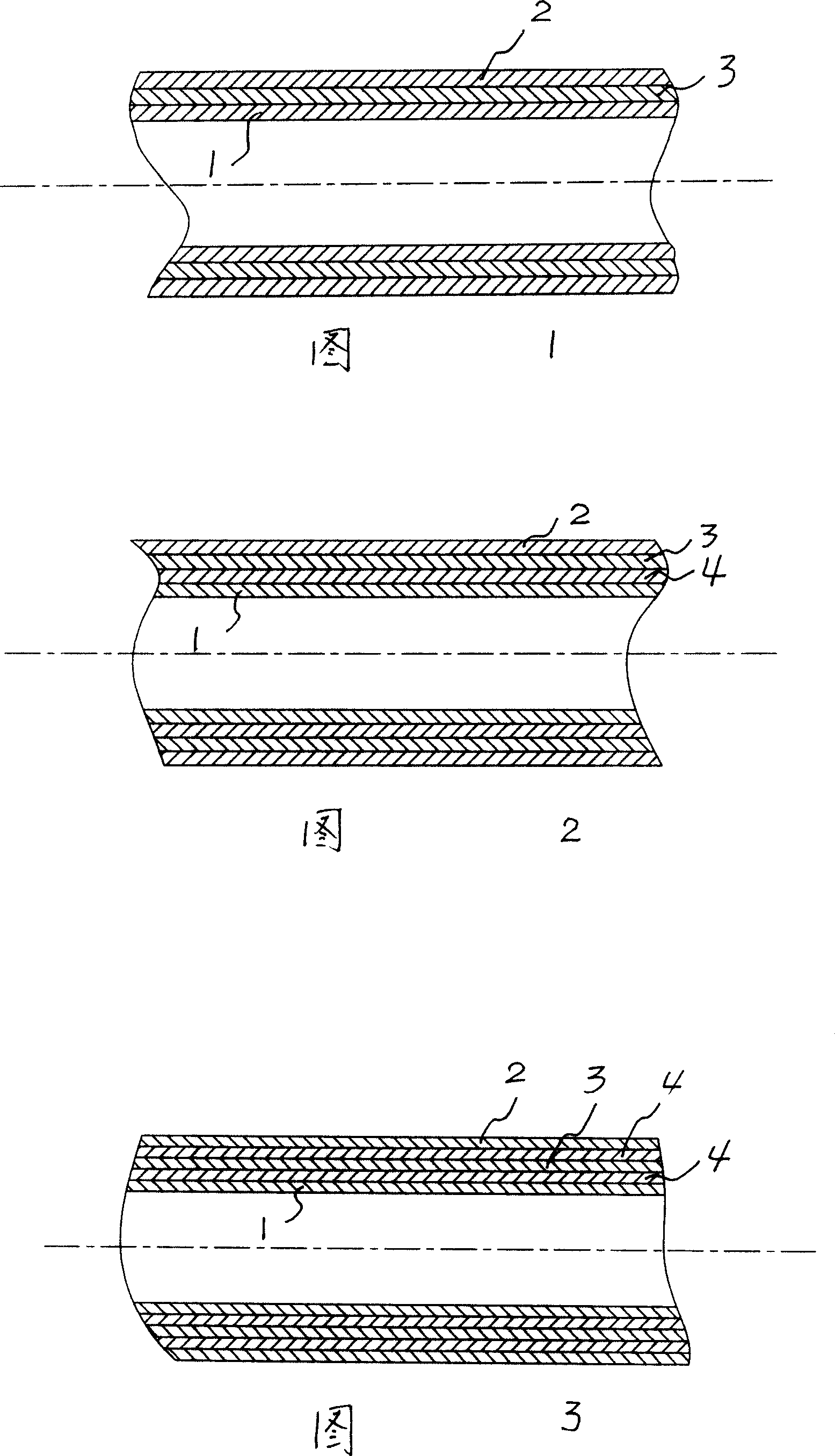

[0020] The structure of Example 1 is shown in Figure 1, an alkali-activated inorganic gelled mortar interlayer composite pipe has a glass fiber reinforced plastic inner liner 1, a glass fiber reinforced plastic outer protective layer 2, the glass fiber reinforced plastic inner liner 1 and the glass fiber reinforced plastic outer protective layer 2 There is an alkali-activated inorganic gelled sand layer 3 between them, and the production process is basically the same as that of the prior art, that is, it is produced according to the following procedures:

[0021] Making FRP inner lining layer 1——Curing FRP inner lining layer 1——Making alkali-activated inorganic gelled sand layer 3——Alkali-activated inorganic gelled sand layer 3 Curing——Making FRP outer protective layer 2——FRP outer layer The protective layer 2 is cured——making the socket——pipeline demoulding——inspection and storage.

[0022] Concrete method of operation is completely the same as prior art:

[0023] 1. Make th...

Embodiment 2

[0044] The structure of embodiment 2 is as shown in Figure 2, has glass fiber reinforced plastic lining layer 1, has fiberglass steel structure layer 4 outside the glass fiber reinforced plastic lining layer 1, and the outside of glass fiber reinforced plastic structure layer 4 has alkali-activated inorganic gelled sand layer 3, and alkali excitation The outside of the inorganic gelled sand layer 3 has a glass fiber reinforced plastic outer protective layer 2 .

[0045] Technology is substantially the same as embodiment 1, and production procedure is completely identical with prior art, promptly makes by following procedure:

[0046] Making FRP lining layer 1——Curing FRP lining layer 1——Making FRP structural layer 4——FRP structural layer 4 Curing——Making alkali-activated inorganic gelled sand layer 3——Alkali-activated inorganic gelled sand layer 3 Curing - making the outer protective layer of FRP 2 - outer protective layer of FRP 2 Curing - making the socket - demoulding the p...

Embodiment 3

[0049] The structure of Example 3 is shown in Figure 3: the others are the same as in Example 2, except that a glass fiber reinforced plastic structure layer 4 is made between the alkali-activated inorganic gelled sand layer 3 and the glass fiber reinforced plastic outer protective layer 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com