Stop valve

A globe valve and valve stem technology, applied in the direction of lift valve, valve device, engine components, etc., can solve the problems of the globe valve is not closed tightly, the switch is not flexible enough, the grinding groove is closed, etc., to achieve less maintenance, avoid spiral type movement, the effect of reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

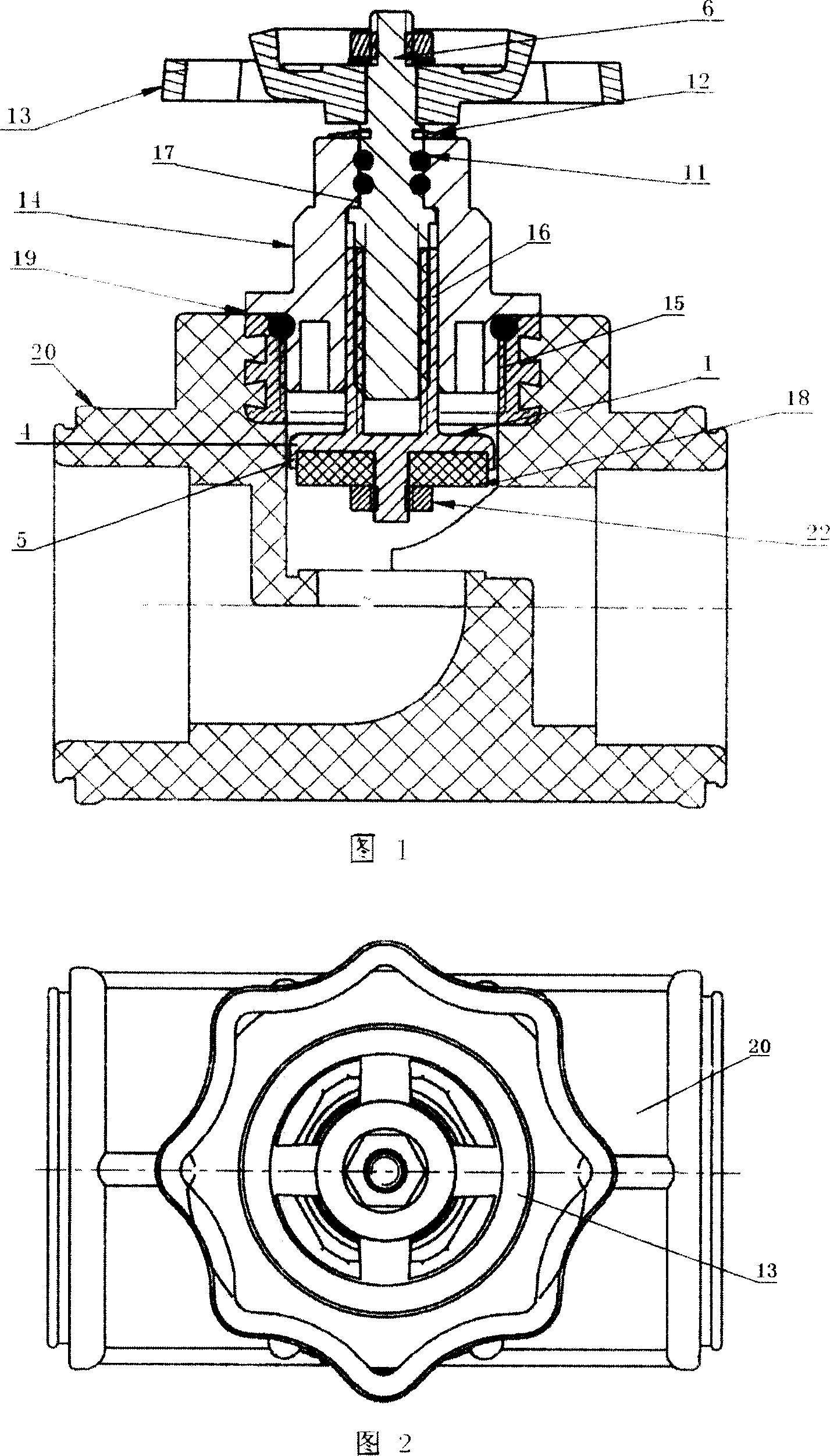

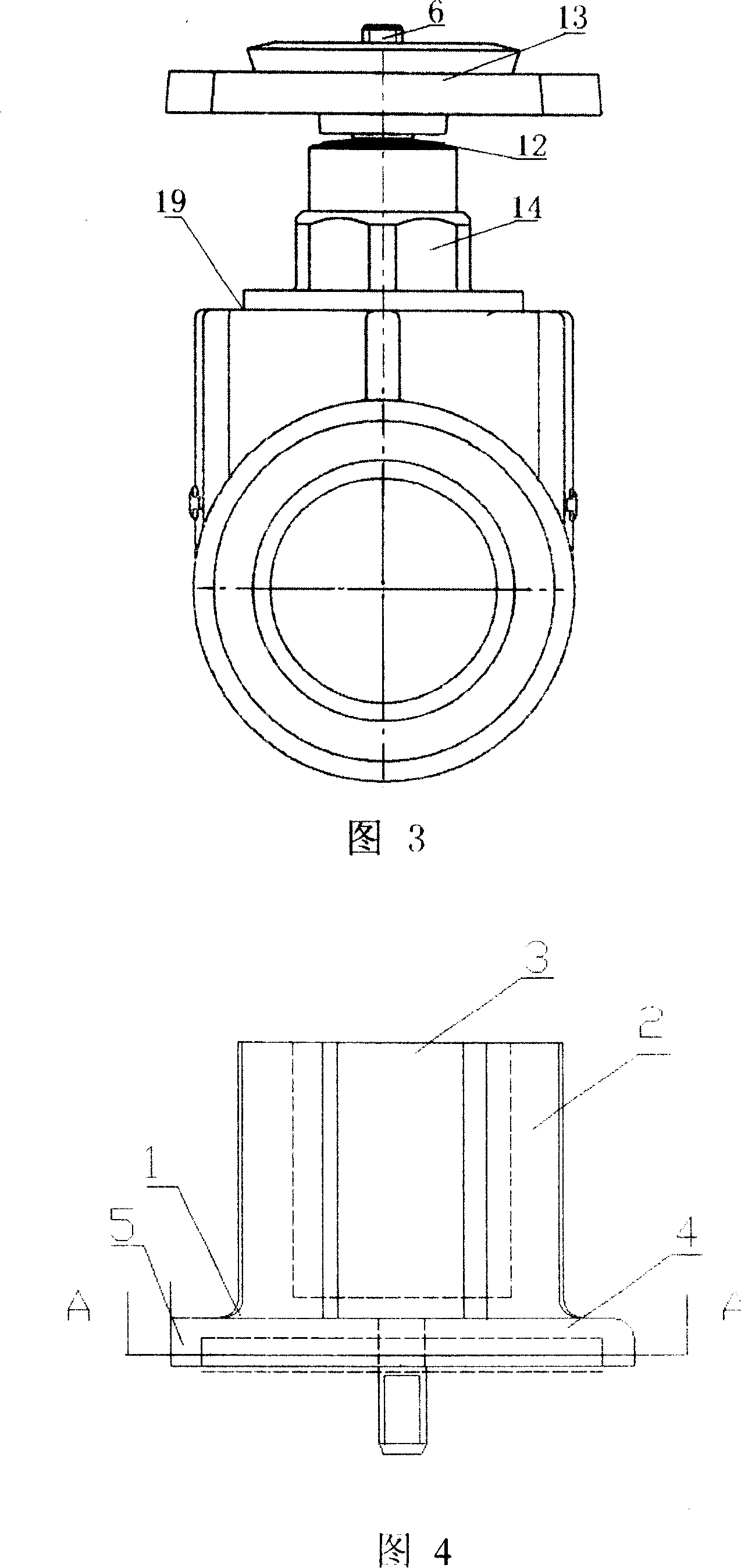

[0027] A globe valve, comprising a valve body 20, a gland 14, a valve stem 6, and a valve core 1, the valve stem 6 is threadedly connected to the valve core 1 and penetrates into the upper hole 17 of the gland 14, and is installed together with the gland 14 On the upper port 19 of the valve body 20, as shown in Figure 1-7.

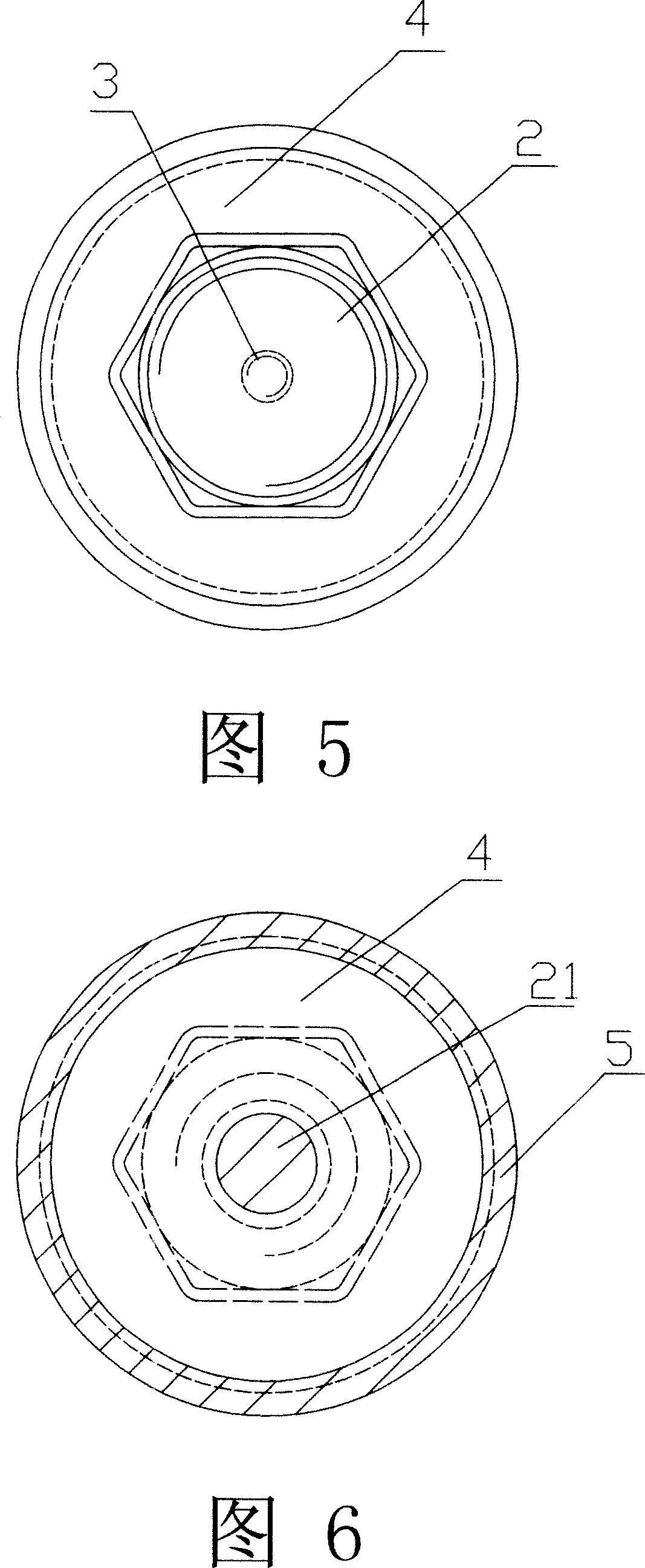

[0028] The upper part of the valve core 1 is a hexagonal prism 2, the upper center of the hexagonal prism 2 is provided with a screw hole 3, the lower part of the valve stem 6 is a thread 7, and the valve stem 6 is threadedly connected with the screw hole 3 at the center of the upper end of the valve core 1, the valve The rod 6 is connected with the valve core 1 and penetrates the hexagonal prism-shaped hole 16 at the bottom of the gland 14 and the round hole 17 at the top of the gland 14. The upper end of the valve stem 6 is provided with a thread 8 and is threadedly connected with the handwheel 13. The bottom is provided with an annular positioning groov...

Embodiment 2

[0035] As shown in Figures 8-9, the second embodiment is basically the same as the first embodiment in terms of structure, the difference is that the upper part of the valve core 1 is a hexagonal prism 2 is set as a triangular prism, and the lower end of the gland 14 is correspondingly provided with three The prism-shaped hole and the triangular prism-shaped valve core 1 are installed in the triangular-prism-shaped hole, and the rest are the same as the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com