Robot for eliminating exploding and danger

A robot and machine body technology, applied in the field of robots, can solve problems such as insufficient working ability, unstable center of gravity, and large structure, and achieve the effects of improving the ability to pass through narrow spaces, extending the effective length, and reducing the projected area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

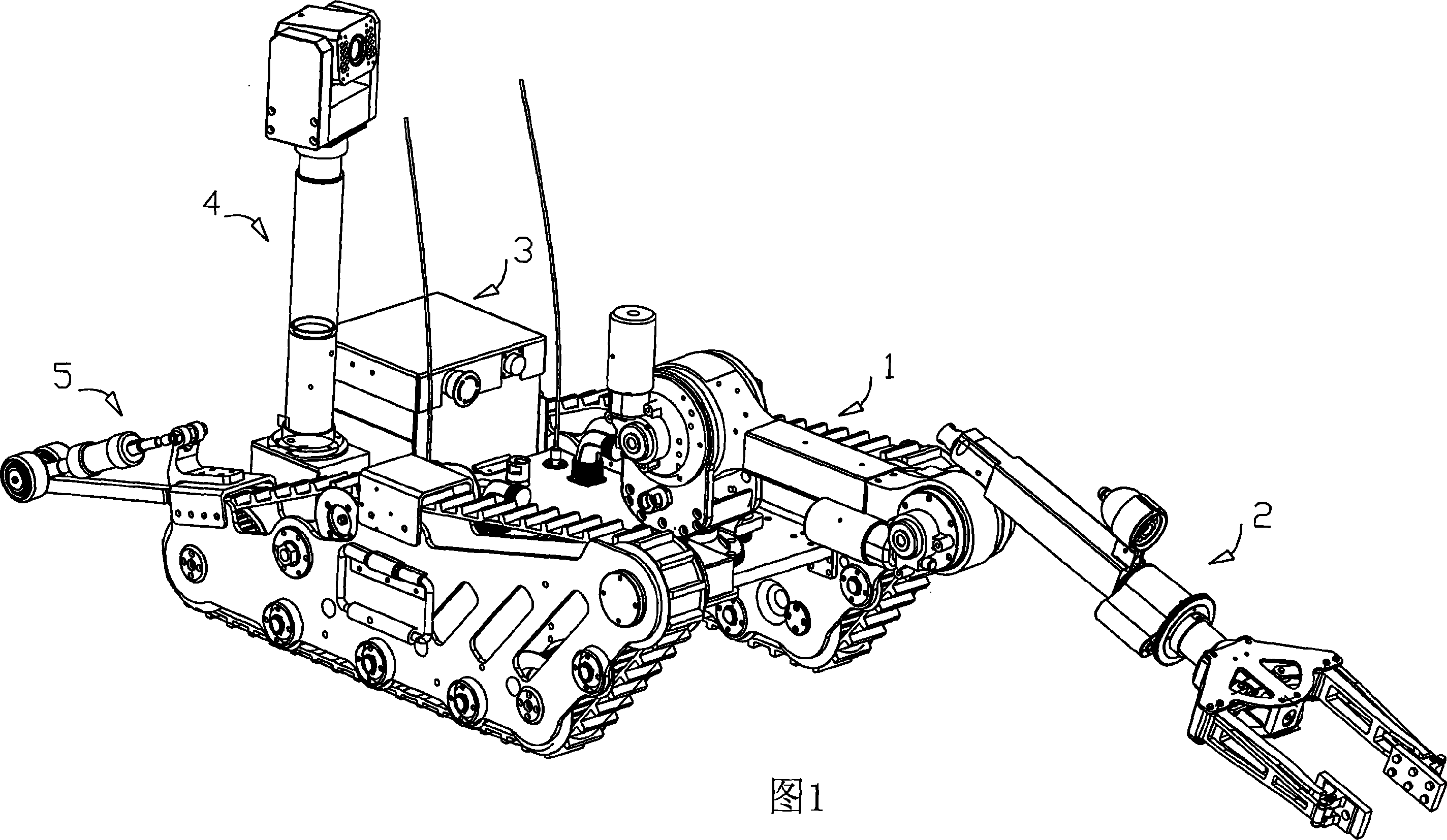

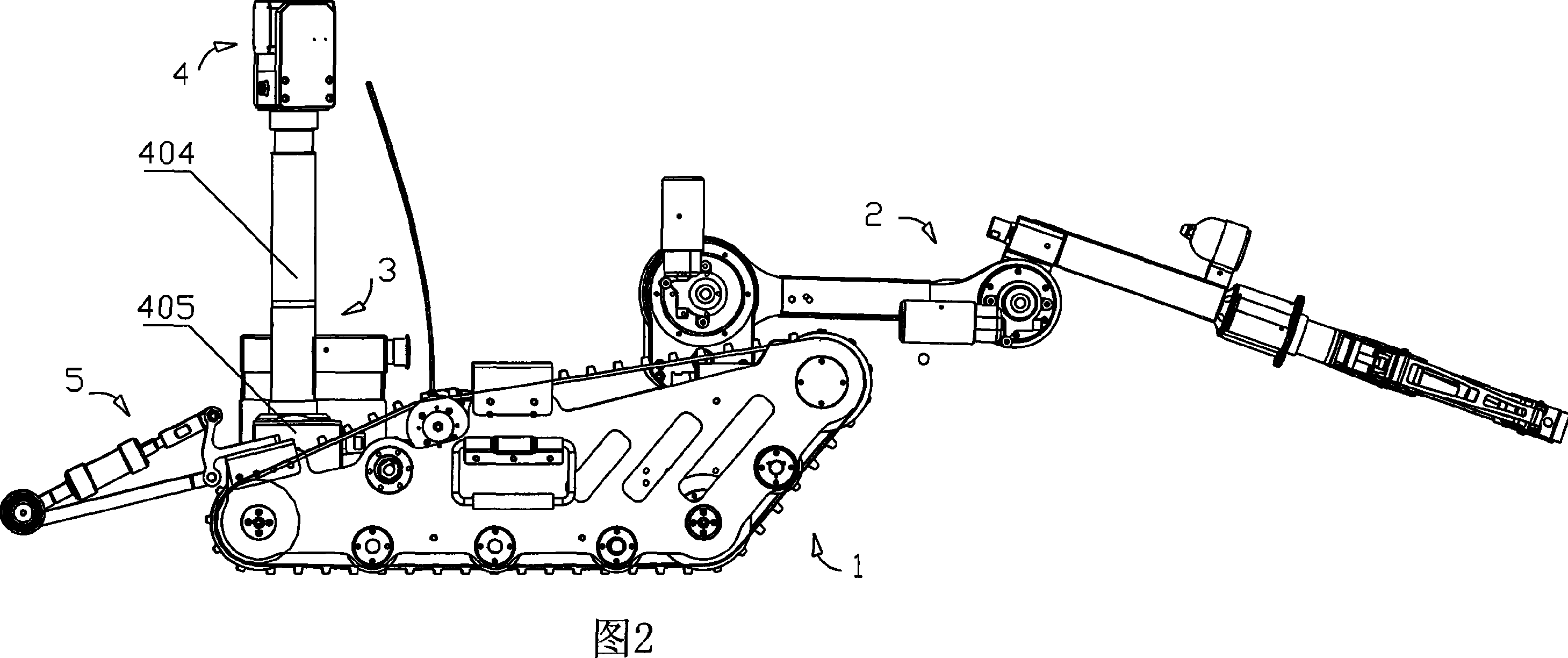

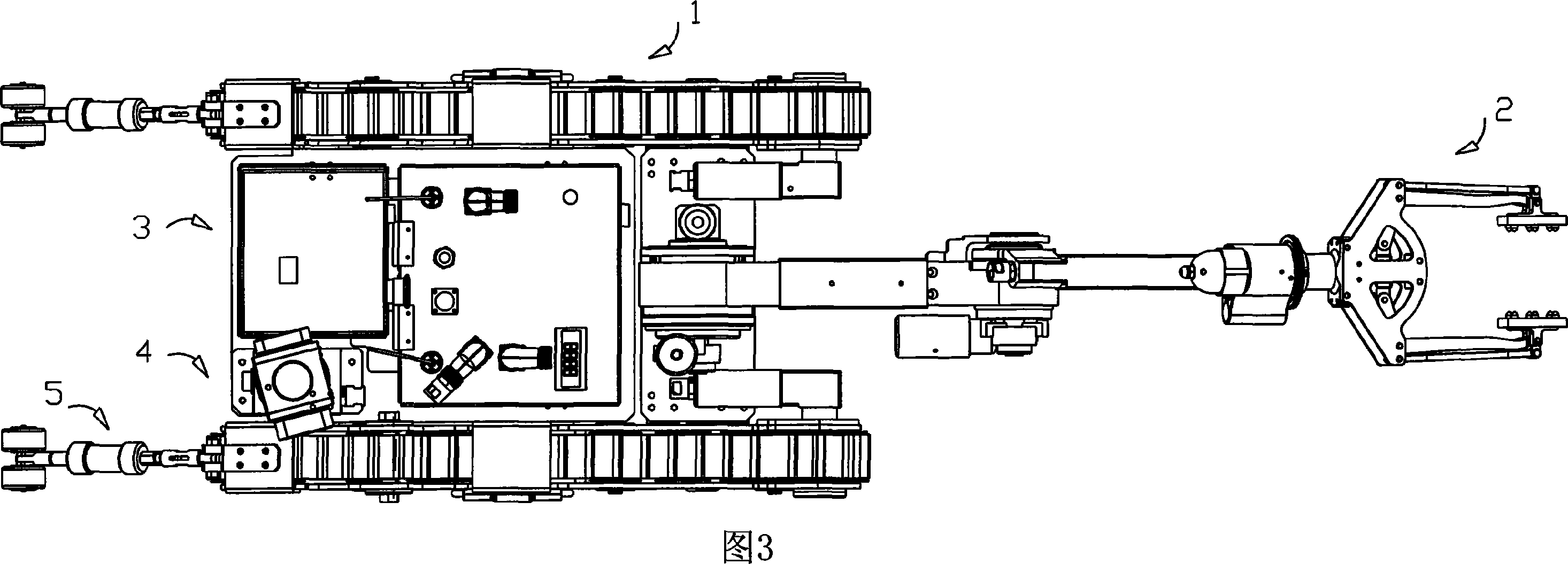

[0040] Referring to Fig. 1, Fig. 2, Fig. 3, and Fig. 4, an explosive and risk-removal robot is mainly composed of a walking part 1, a manipulator part 2, a body part 3, a pan-tilt part 4, a tail support part 5 and a control part, etc. Its body part 3 comprises parts and components such as equipment compartment 301, battery compartment 302, front chassis 303, rear chassis 304, and equipment compartment 301 and battery compartment 302 are respectively an independent part, all are arranged on the rear chassis 304, can disassemble respectively, Maintenance, transportation; the cloud platform part 4 is arranged on the rear chassis 304 of the body part 3; the walking part 1 is left and right two parts, symmetrically connected to the front chassis 303 and the rear chassis 304 both sides of the body part 3; the manipulator part 2 is made into an independent Components are plugged on the front chassis 303 of the body part 3;

[0041]Referring to Fig. 5, the left and right structures of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com