Liquid crystal optical element

A liquid crystal optics, liquid crystal cell technology, applied in optics, nonlinear optics, optical recording heads, etc., can solve the problem that the effective radius of the objective lens has different peak positions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

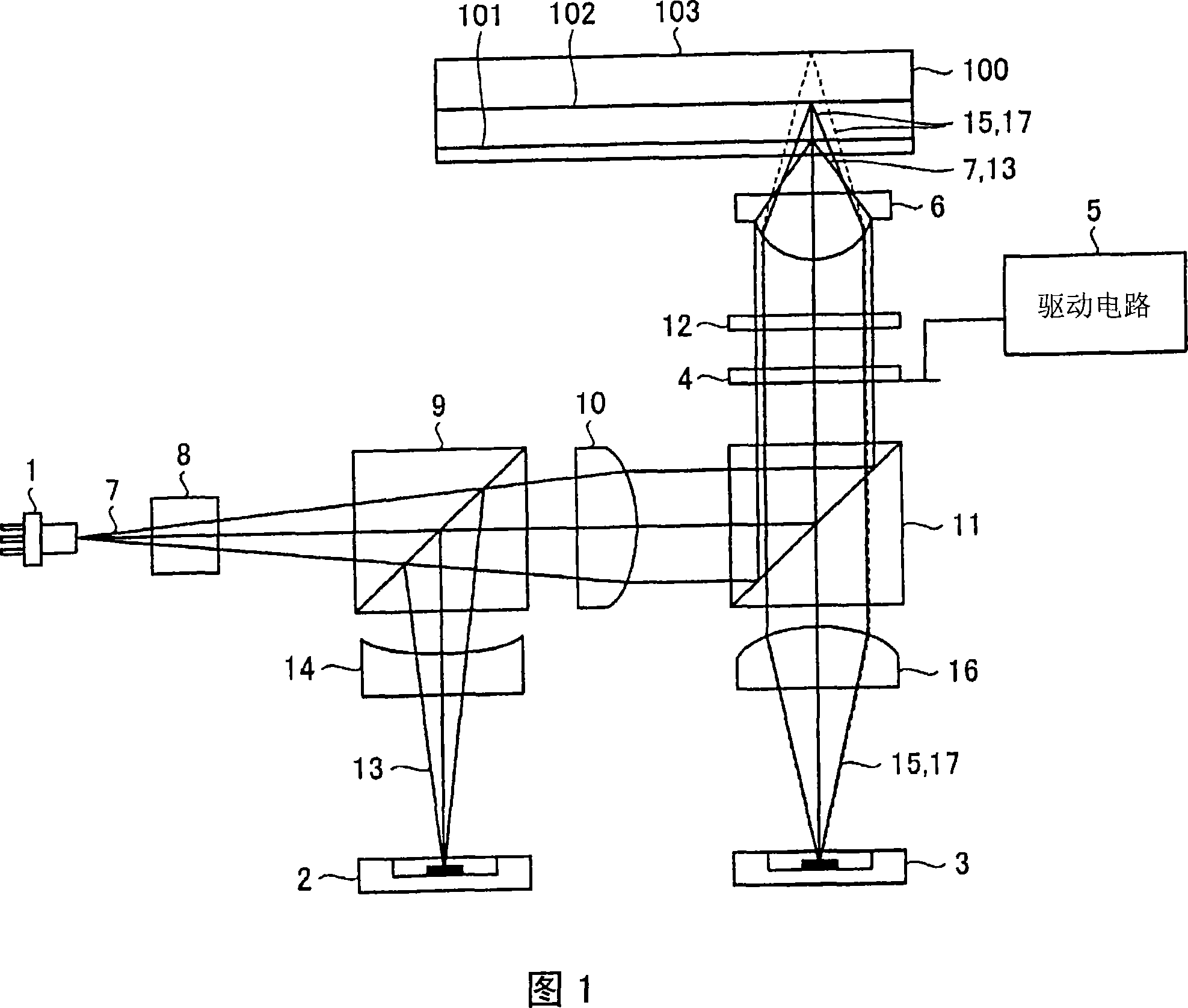

[0116] FIG. 1 is a schematic diagram showing the structure of an optical head device to which the liquid crystal optical element of the present invention is applied. As shown in Figure 1, the optical head device is equipped with: a blue laser light source 1 that emits blue laser light with a wavelength of about 400nm; a blue photodiode 2 that detects the retroreflected light of the laser light emitted from the blue laser light source 1; CD module 3 integrates a laser light source that emits infrared laser light with a wavelength of about 780nm and a red laser light with a wavelength of about 660nm, and a photodiode that detects each retroreflected light; constitutes a liquid crystal optical element that performs wavefront control such as spherical aberration correction The liquid crystal unit 4 of the main part; the driving circuit 5 and the objective lens 6 that constitute the power supply part of the liquid crystal optical element.

[0117] The blue laser light 7 emitted fro...

Embodiment approach 2

[0144] In Embodiment 2, concentric electrodes are provided on both the first electrode and the second electrode. For the same configuration as in Embodiment 1, the same symbols as in Embodiment 1 are assigned, and description thereof will be omitted. 13 and 14 are diagrams showing patterns of the first electrode 121 and the second electrode 123 in Embodiment 2, respectively. In addition, FIG. 15 is a diagram schematically showing the relationship between the first and second electrodes 121 and 123 and the voltage applied therebetween.

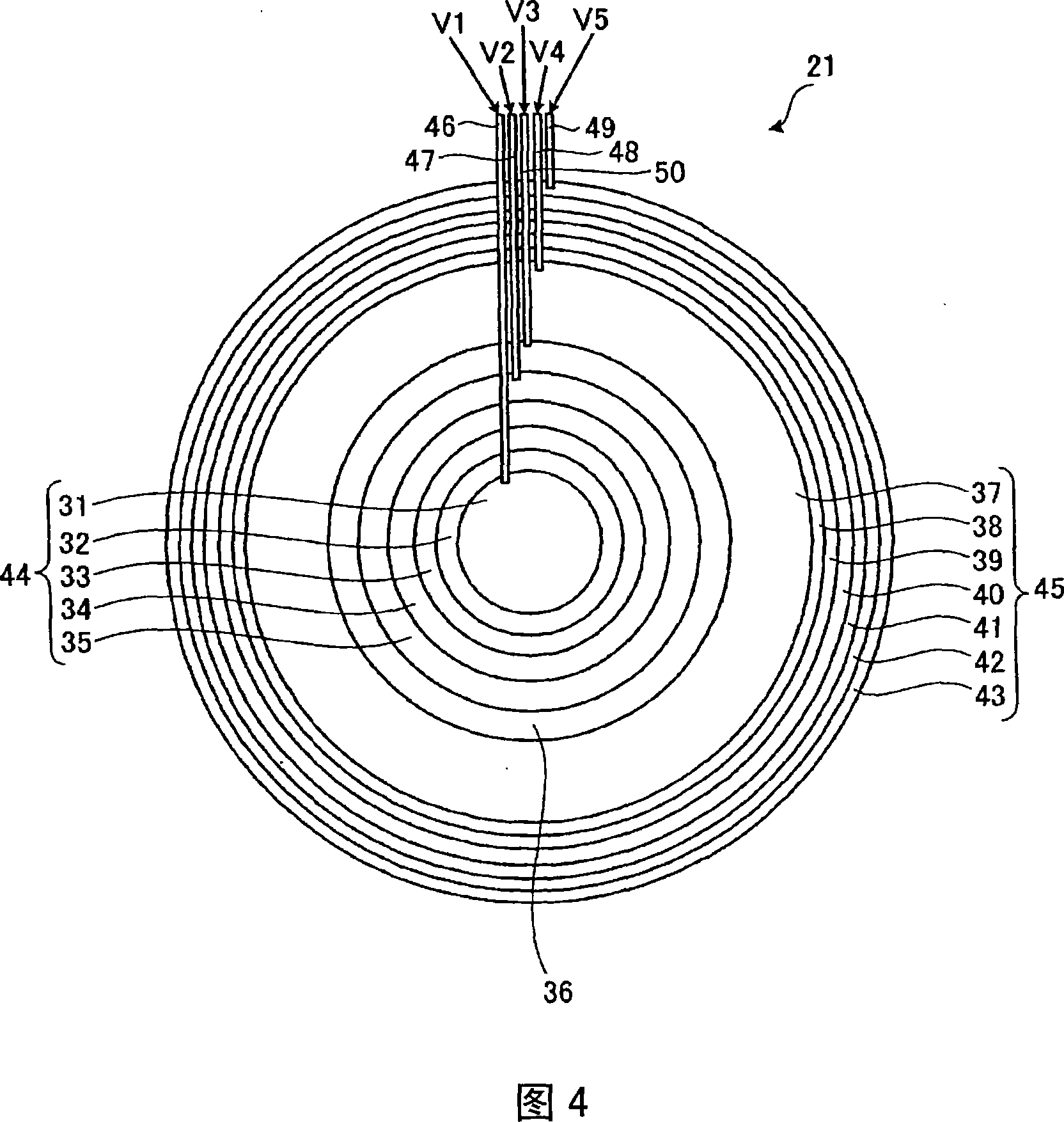

[0145] As shown in FIG. 13 , on the first electrode 121 , a sixth concentric electrode (individual concentric electrode) 36 and seventh to thirteenth concentric electrodes 37 to 43 connected by resistors as in the first embodiment are provided. The inner side of the sixth concentric electrode 36 , that is, the region where the first to fifth concentric electrodes 31 to 35 are provided in Embodiment 1 becomes a uniformly circular 14th concentri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com