Packaging structure of conducting wire holder on multi-chip stacking structure

A technology of stack structure and packaging structure, applied in the direction of semiconductor devices, semiconductor/solid-state device parts, electrical components, etc., can solve the problems of metal wire displacement, electrical signal phase change, and different lengths of metal wires.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

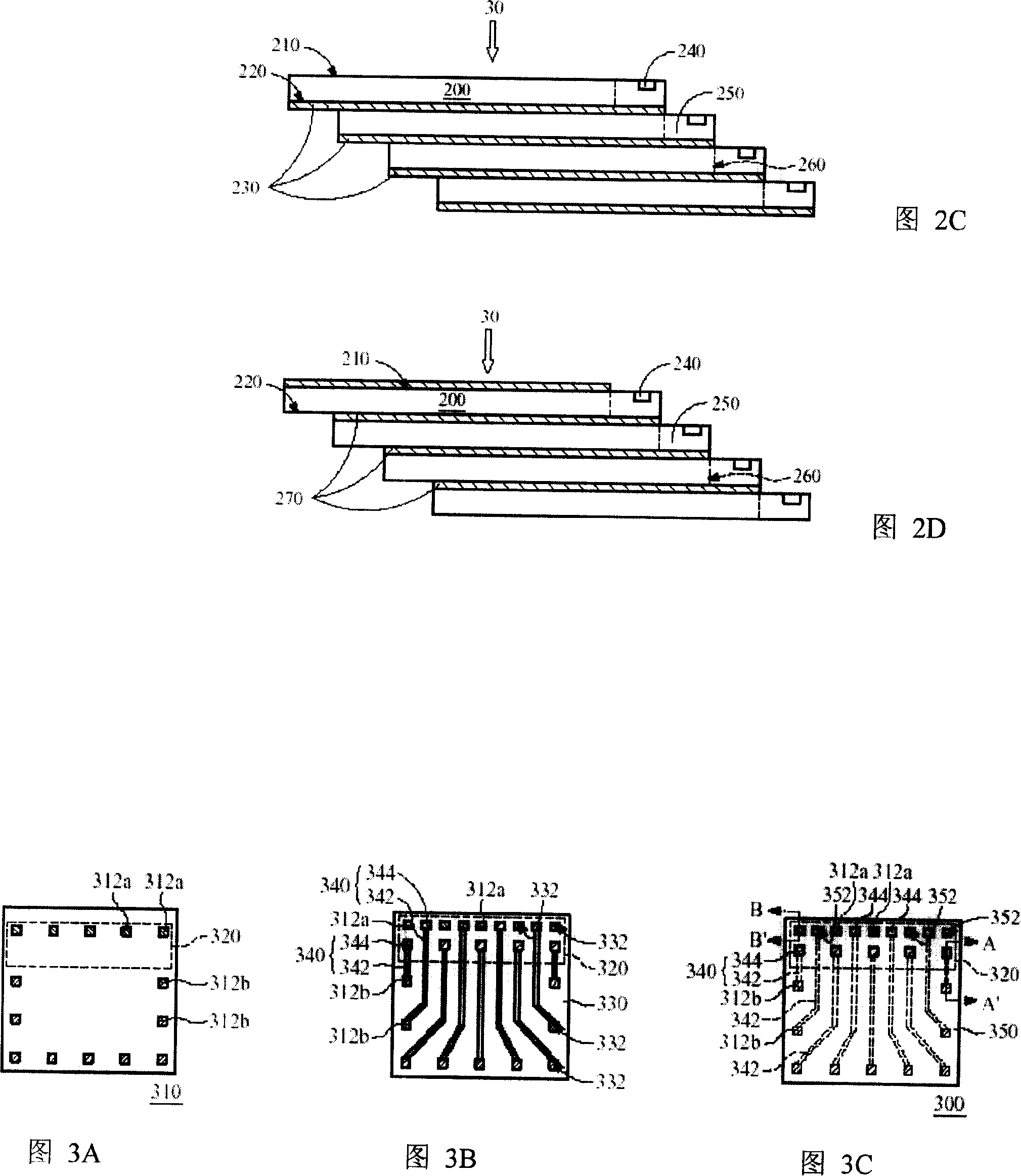

[0064] As shown in FIGS. 2A and 2B , a schematic plan view and a schematic cross-sectional view of a chip 200 that has completed the foregoing processes. As shown in Figure 2B, the chip 200 has an active surface 210 and a back surface 220 opposite to the active surface, and an adhesive layer 230 has been formed on the chip back surface 220; it should be emphasized here that the adhesive layer 230 of the present invention is not limited to the above-mentioned The above-mentioned semi-cured glue, the purpose of the adhesive layer 230 is to form a bond with the substrate or the chip, therefore, as long as it is an adhesive material with this function, it is an embodiment of the present invention, such as a die attached film.

[0065] Next, please refer to FIGS. 2C and 2D , which are cross-sectional schematic diagrams of a multi-chip offset stacking structure 30 completed by the present invention. As shown in FIG. 2C, a plurality of welding pads 240 are arranged on the active surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com