High-temperature mechanical property testing system of annular tunnel lining structure system

A test system and high-temperature mechanics technology, applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc., can solve the problem of not considering the impact of high-temperature mechanical properties of surrounding rock and soil, low maximum temperature, and heating rate. Slow and other problems, to achieve the effect of improving work efficiency and data accuracy, high maximum temperature, and small temperature fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

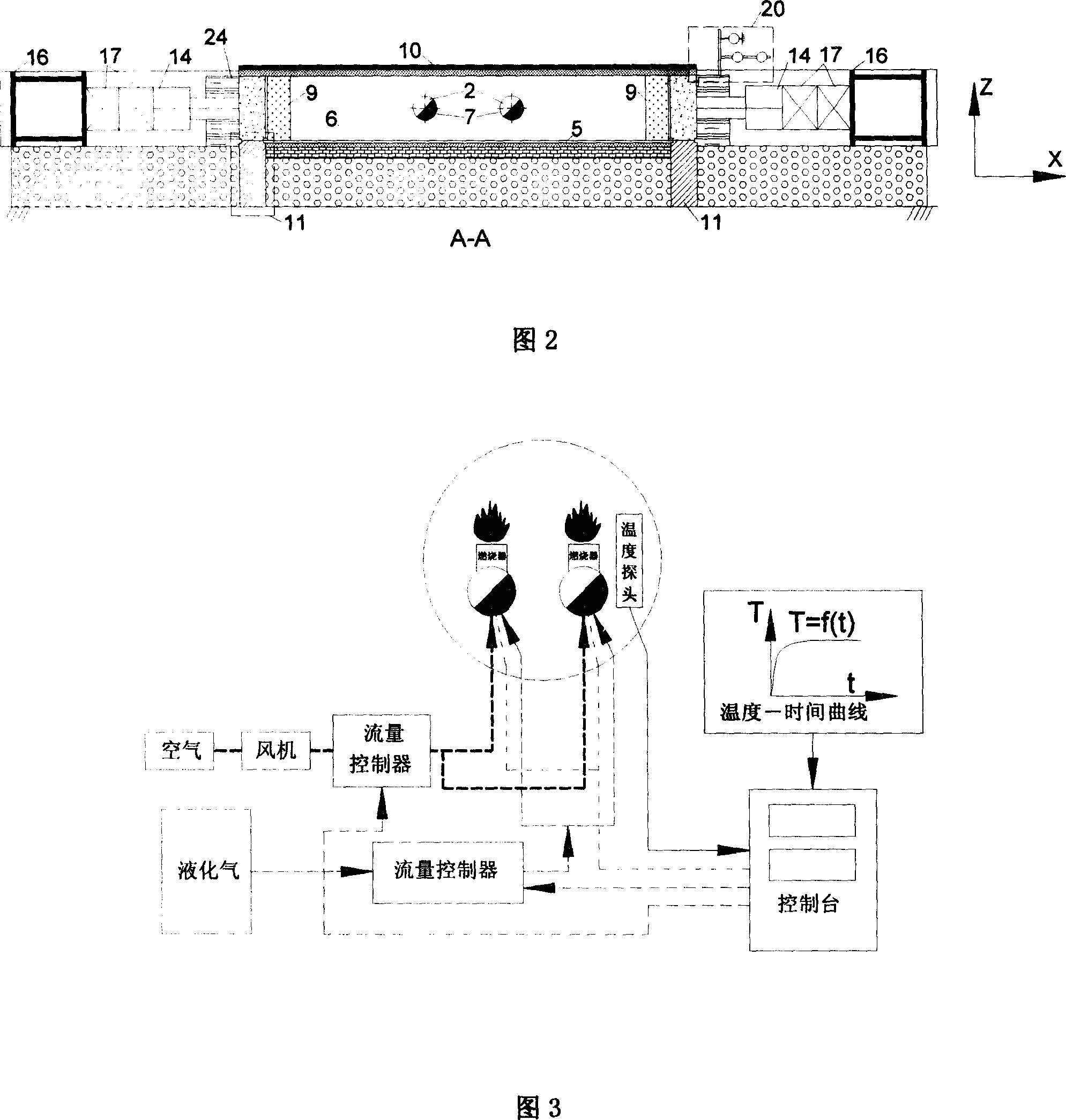

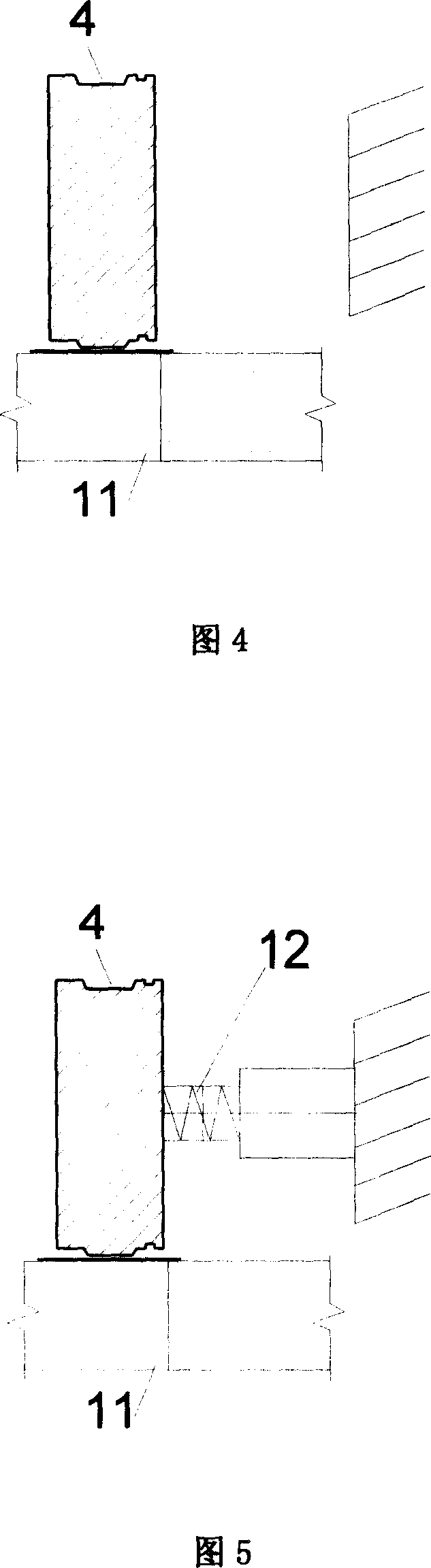

[0040] As shown in Figure 1, the high-temperature mechanical performance test system of the circular tunnel lining structure system of the present invention is composed of the following seven subsystems with specific functions:

[0041] (1) Fire thermal environment simulation subsystem;

[0042] (2) Thermal insulation subsystem;

[0043] (3) The mechanical boundary simulation subsystem of the foundation and lining structure system;

[0044] (4) loading subsystem;

[0045] (5) Measurement subsystem;

[0046] (6) Data acquisition subsystem;

[0047] (7) The thermal boundary simulation subsystem of the lining structure system.

[0048] In terms of spatial layout, the test system adopts a horizontal layout, that is, the axis of the annular tunnel lining structure system is placed vertically upward during the test. Due to the horizontal layout, it is very convenient to install the lining structure system, apply loads, arrange measuring points, apply thermal boundaries (covering ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com