Method for nondestructive detecting length of high speed highway guardrail upright post by ultrasonic guided wave

A guardrail post, non-destructive testing technology, applied in the direction of using ultrasonic/sonic wave/infrasonic wave, re-radiation of sound wave, using re-radiation, etc., can solve the problems of shortening guardrail post, post corrosion fracture, guardrail post corrosion, etc., and achieve detection accuracy High, low detection cost, fast detection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with content of the present invention provide following embodiment:

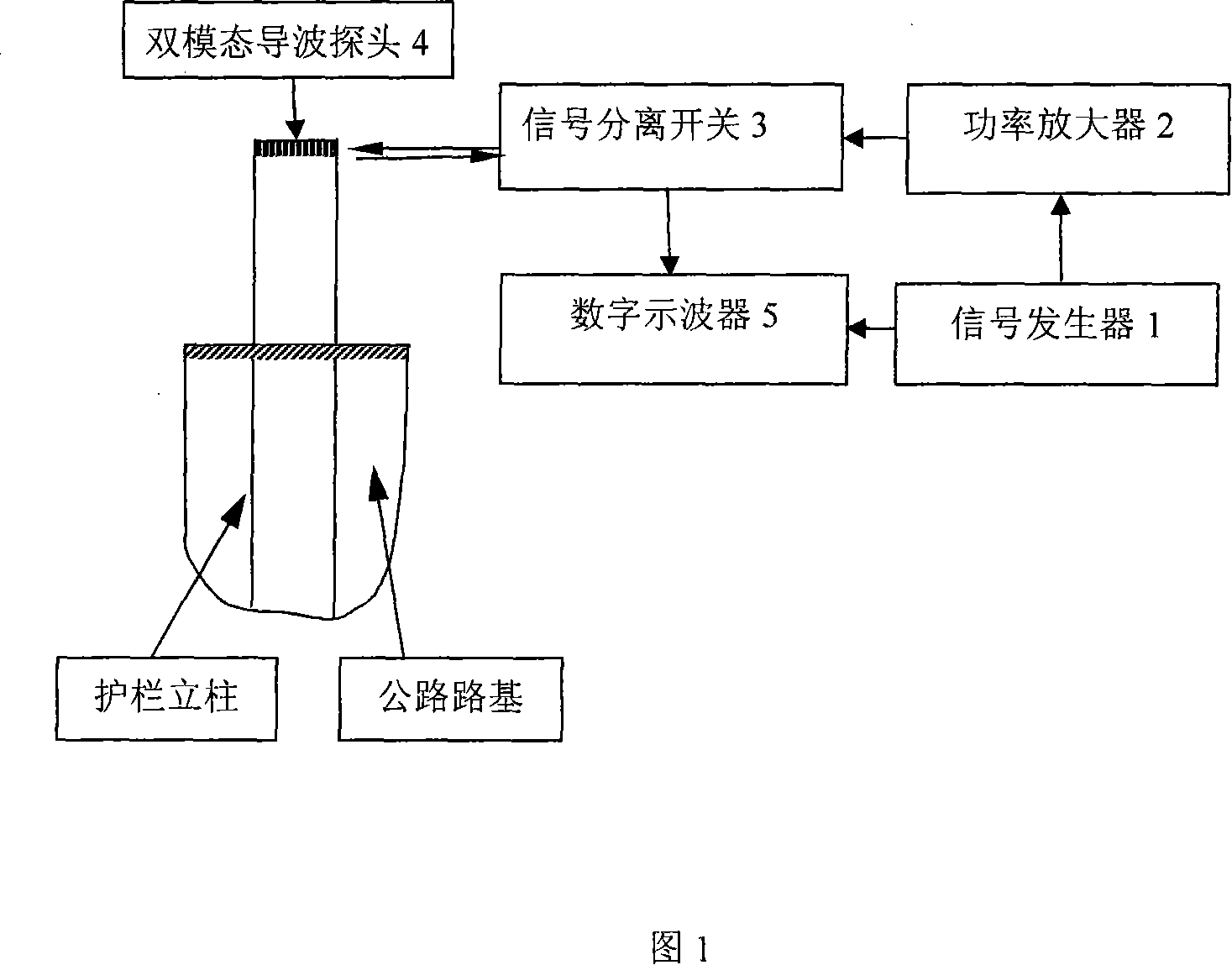

[0016] As shown in Figure 1, the upright column in this embodiment is a seamless steel pipe with a length of 1800mm, an inner diameter of 105mm, an outer diameter of 114mm, and a wall thickness of 4.5mm. The density is 7800kg / m 3 , the longitudinal wave velocity is 5960m / s, and the transverse wave velocity is 3260m / s. The surrounding medium is 1.7g / cm 3 of compacted soil.

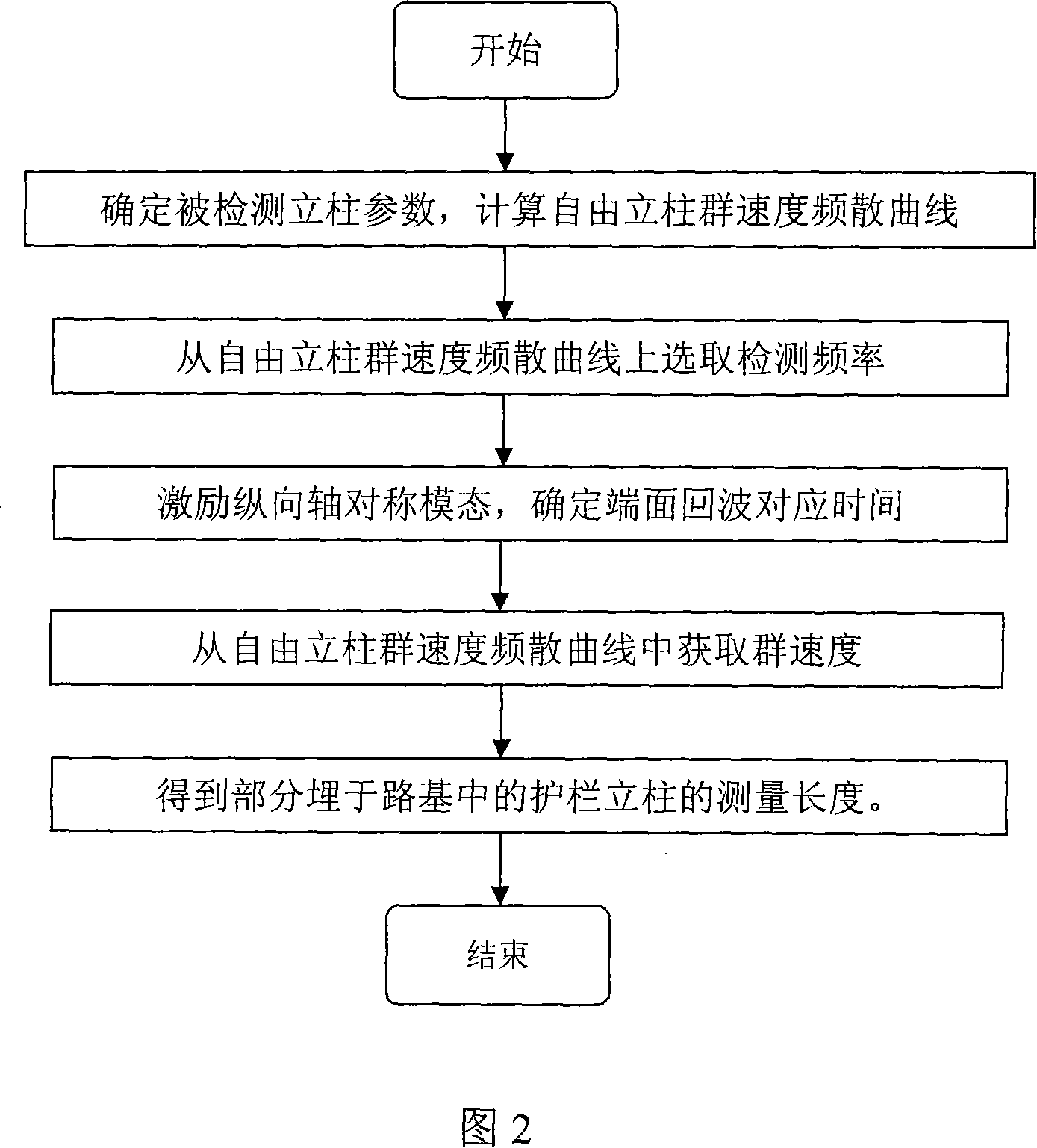

[0017] 1) Calculate the group velocity dispersion curve according to the parameters of the guardrail column and subgrade soil, and select the frequency corresponding to the group velocity of 5340m / s mode as the detection frequency 100kHz in the range of 50-200kHz;

[0018] 2) Input the detection frequency into the arbitrary function generator 1, and the arbitrary function generator 1 generates a single audio signal with a center frequency of 100kHz. The voltage is amplified through the power amplification m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com