Electrostatic resistance applying liquid composition and manufacture of high penetrance electrostatic resistance film

An antistatic, coating liquid technology, applied in the direction of coating, epoxy resin coating, other chemical processes, etc., can solve the problems of antistatic film color shift, difficult to store, damage the wear resistance of antistatic film, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

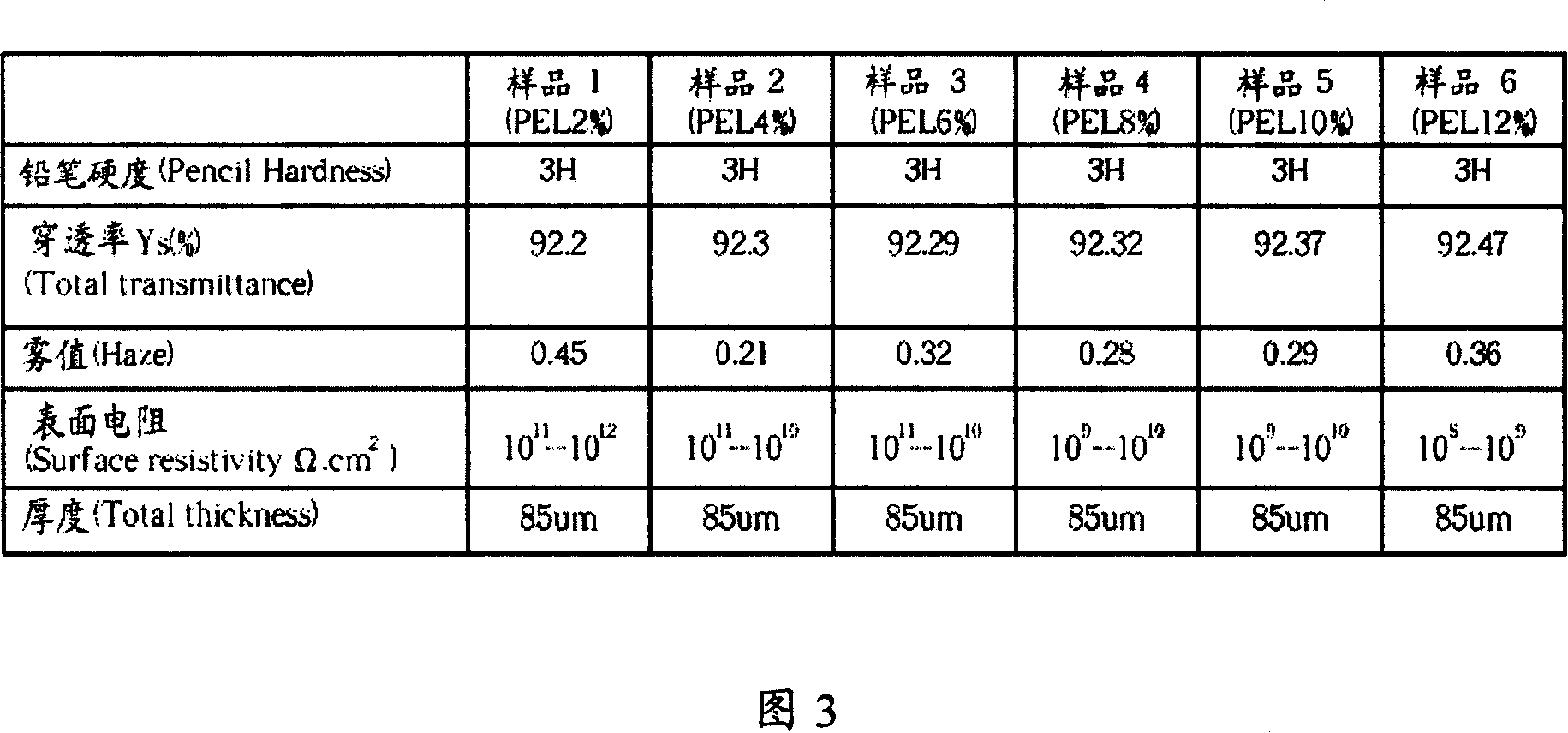

[0047] In order to enable those skilled in the art to more clearly understand the spirit, technical characteristics and advantages of the present invention, the following examples illustrate the detailed preparation process of the ionic antistatic coating solution of the present invention and the test results of the antistatic film. The invention provides a preparation method of an antistatic hard coating with simple preparation method, high storage stability and no dispersion problem.

[0048] 1. Preparation of ionic antistatic coating solution

[0049] Preparation of hard coat coating liquid: get the commercial hard coat material RC-610R of Nissan Chemical Company, which is an ultraviolet curable acrylic resin, and then mix ethyl acetate (ethyl acetate) with a volume ratio of 1:1:1 , isopropanol (isopropanol, IPA), 1-methoxy isopropanol (1-methoxy-2-propanol) form a solvent, and then RC-610R is formulated into a hard coat coating with a solids content of 40% by weight liqui...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com