Pneumatic transmission mode for powder and device thereof

A transmission device and fine powder technology, which is applied in the direction of transportation and packaging, conveying bulk materials, conveyors, etc., can solve the problems of complex control system, complex structure of the device, and small conveying volume, so as to make full use of the workshop area and easily adapt to the workshop Environment, effect of preventing clogging problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

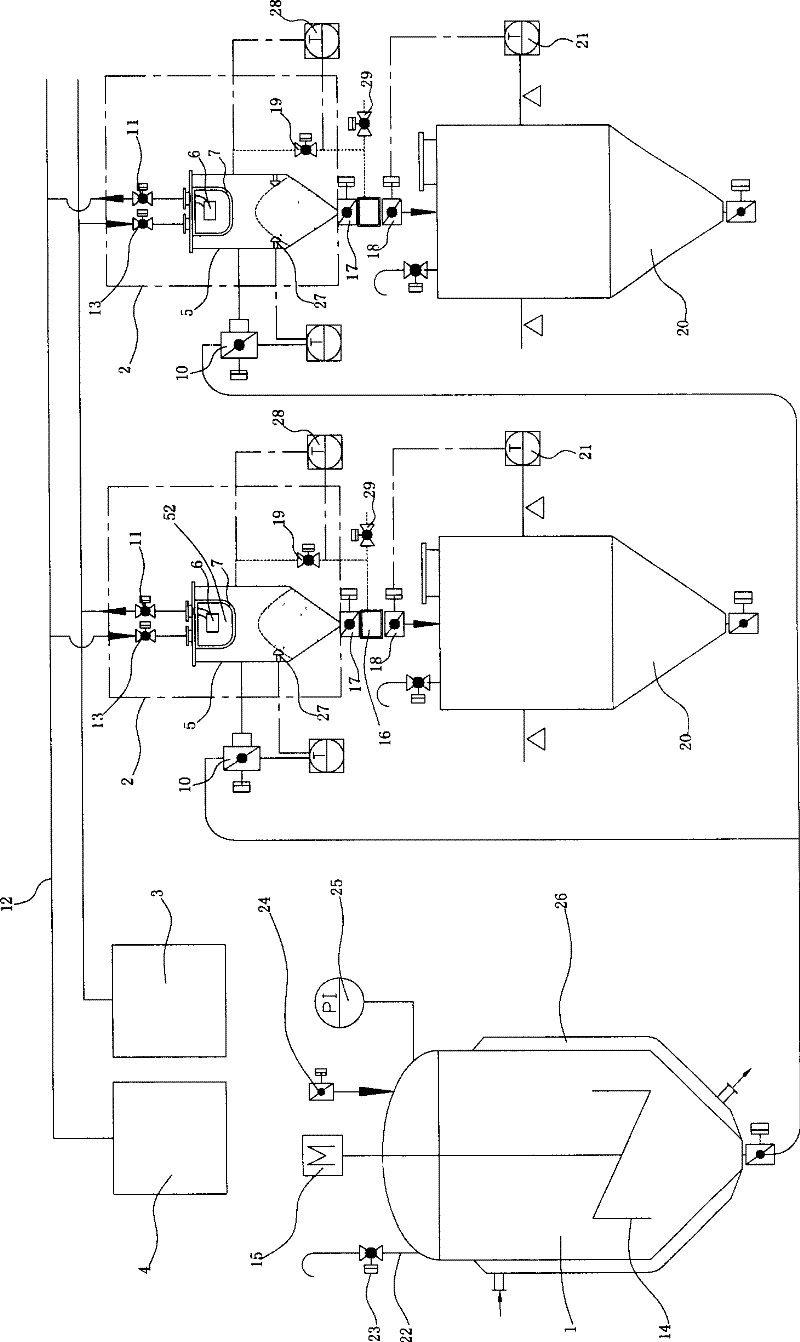

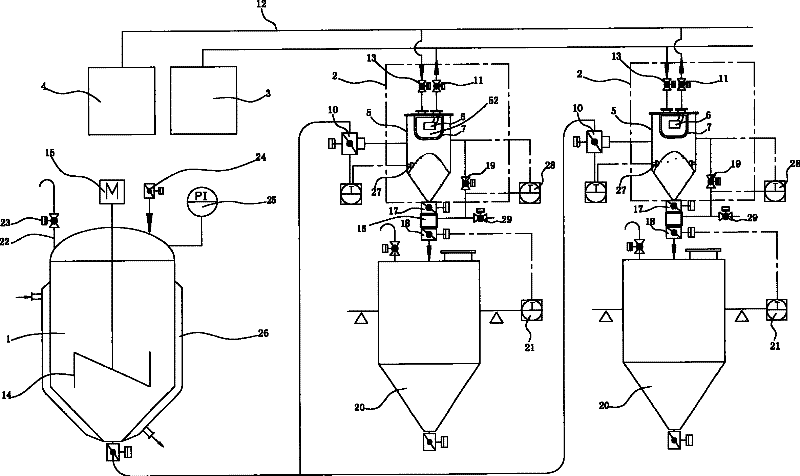

[0017] A kind of fine powder pneumatic transmission method, in conjunction with shown in Fig. 1, comprises the steps:

[0018] Step 1. The fine powder is sucked from the first storage tank 1 at the sending end through the fine powder transmission pipeline 8 to the second storage tank 5 at the receiving end by means of negative pressure generated by the air extractor 3;

[0019] Step 2: Install a powder gas separation device 7 in the second storage tank 5 at the receiving end to separate the mixture of fine powder and gas from the pipeline, so that the fine powder remains in the fine powder storage area 51, and the gas passes through to generate negative pressure The aspirator 3 sucks and then discharges.

[0020] Step 3: The compressed air generated by a compressor 4 passes through the air pulse valve 6, and impacts the powder-air separation device 7 with a large air flow every 10 seconds, so that the fine powder attached to the powder-gas separation device 7 is blown off to p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com