Step walking type pipeline cleaning robot

A pipeline cleaning and walking technology, which is applied in the field of walking pipeline cleaning robots, can solve the problems of not being able to observe the internal conditions of the pipeline, the cleaning quality of the pipe wall cannot be guaranteed, and the cleaning head can maintain a centered position, so as to ensure the reliability of the work and Ease of maintenance, improvement of flexibility and stability, effects of reducing the number of connection elements and piping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

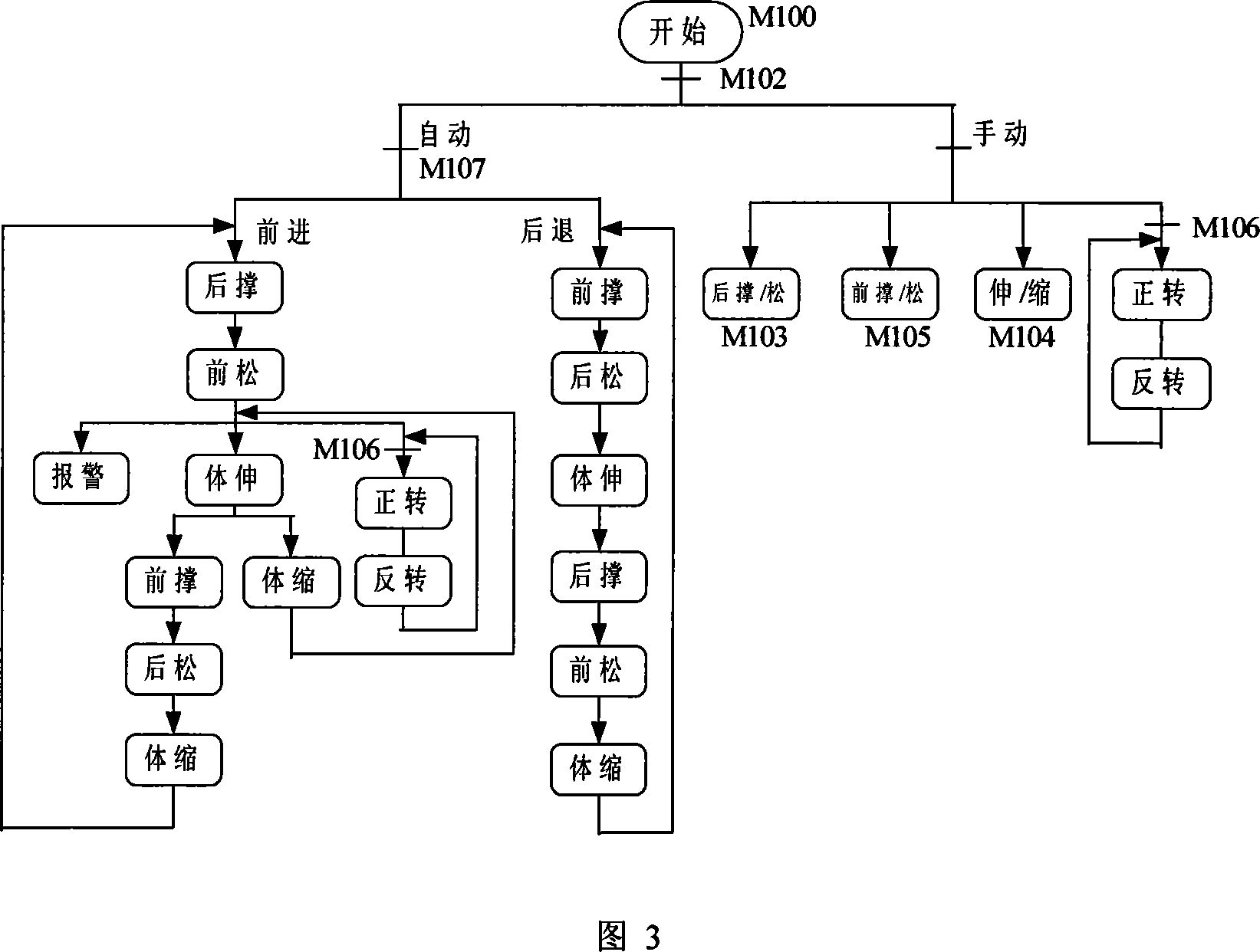

[0019] As shown in Figure 1, the specific details of the mechanical structure of the present invention are: the robot is composed of a walking part and a functional part.

[0020] Mainly include cleaning head (1), rotary cylinder (2), walking cylinder (8), front clamping cylinder (4), front air distribution plate (5), rear clamping cylinder (12), rear air distribution plate (13) ), bracing heads (3, 11), intermediate connecting discs (7), ball hinges (6), guide wheels (10) and sleeves (16). The front and rear radial bracing mechanisms of the walking part are respectively composed of four front and rear bracing cylinders (4, 12), bracing heads (3, 11) and front and rear air distribution plates (5, 13) that are uniformly distributed in the radial direction. The walking cylinder (8) imitates the telescopic action of the human body to achieve step-like walking. The front and rear surfaces of the walking cylinder are fixed with the middle connecting plate (7) and the rear valve plate (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com