Technique for processing instant margaryamelanoides can

A technology of snail and canned food, which is applied in the field of deep processing of aquatic products, can solve the problems of large-scale and standardized production of green snail products, short shelf life, and impact on the quality of snail meat, which have not yet been formed. Guaranteed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

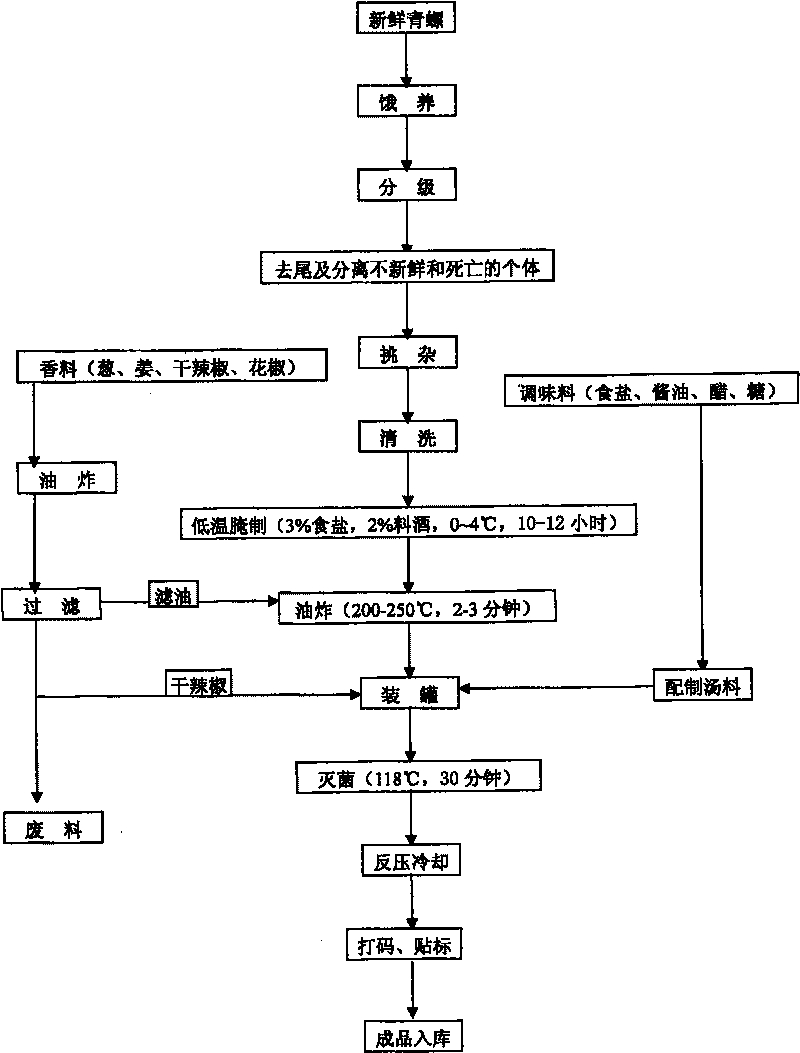

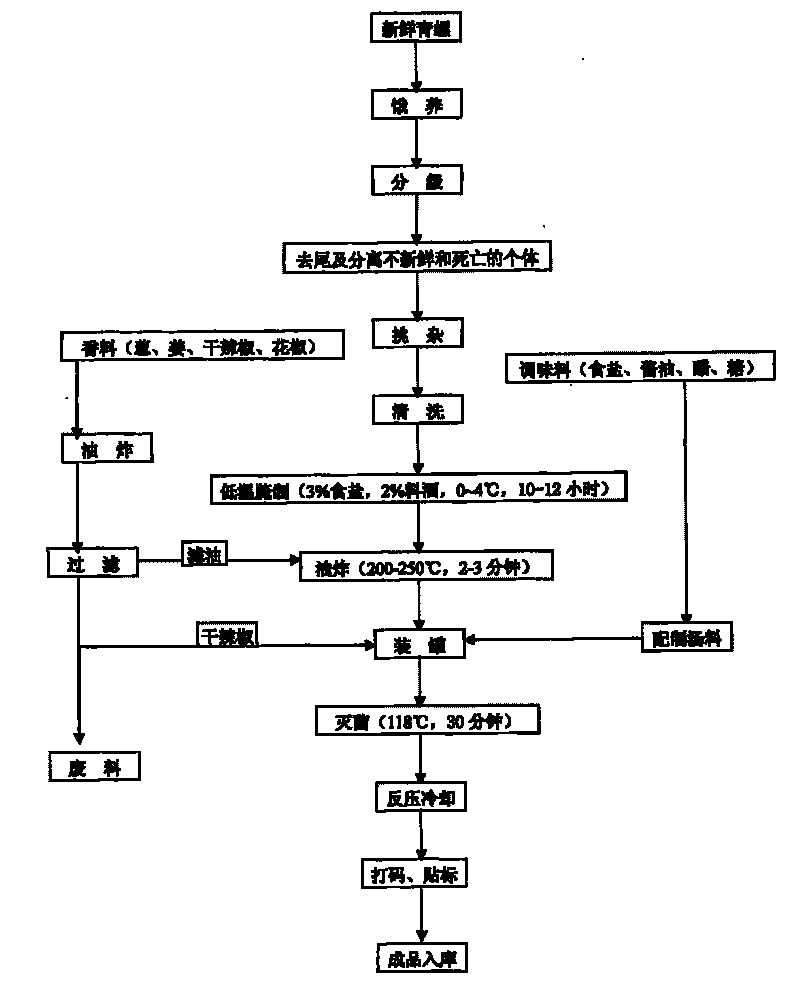

Method used

Image

Examples

Embodiment 1

[0024] 1) Raw material pretreatment: put the fresh green snail raw material into the clear water pond and starve it for 1-2 days, during which the clear water is replaced once, and oxygen is added to prevent the snail from hypoxia death. Sieve and classify after starving, and then (Zhejiang Yongkang Jiangnan Zengxiao Food Machinery Factory) remove the tail, and the tail removal rate is required to reach more than 90%. At the same time, due to the separation of stale and dead individual snail meat, the stale and dead individual snail meat is centrifugally thrown out when the snail drum rolls, making it become an empty shell and separated and removed. After removing the tail, manually pick out impurities, empty shells and some snails whose tails have not been removed, and then clean the raw materials for later use.

[0025] 2) Low-temperature pickling: Take 100kg of pretreated raw materials, add 3kg of salt, 2kg of cooking wine, mix well, put in a 0-4°C cold storage for 10-12 ho...

Embodiment 2

[0032] 1) Raw material pretreatment: put the fresh green snail raw material into the clear water pond and starve it for 1-2 days, during which the clear water is replaced once, and oxygen is added to prevent the snail from hypoxia death. After being starved and raised, they are screened and classified, and then the tails are removed with a drum-type snail automatic tail removal machine. The tail removal rate is required to reach more than 90%. After removing the tail, manually pick out impurities, empty shells and some snails whose tails have not been removed. At the same time, the stale and dead individuals are separated from their flesh and blood. Remove, and then clean the raw materials for later use.

[0033] 2) Low-temperature pickling: Take 100kg of pretreated raw materials, add 3kg of salt, 2kg of cooking wine, and 1kg of white sugar, mix well, and put them in a cold storage at 0-4°C for 10-12 hours, stirring 1-2 times during the process.

[0034] 3) Preparation of spi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com