Waterproof casing mounting method-immersed tube drilling method

A technology of riser casing and installation method, which is applied to earth-moving drilling, drilling equipment and methods, drilling equipment, etc., can solve the problems of platform vibration, uneconomical installation method of riser casing, affecting normal production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

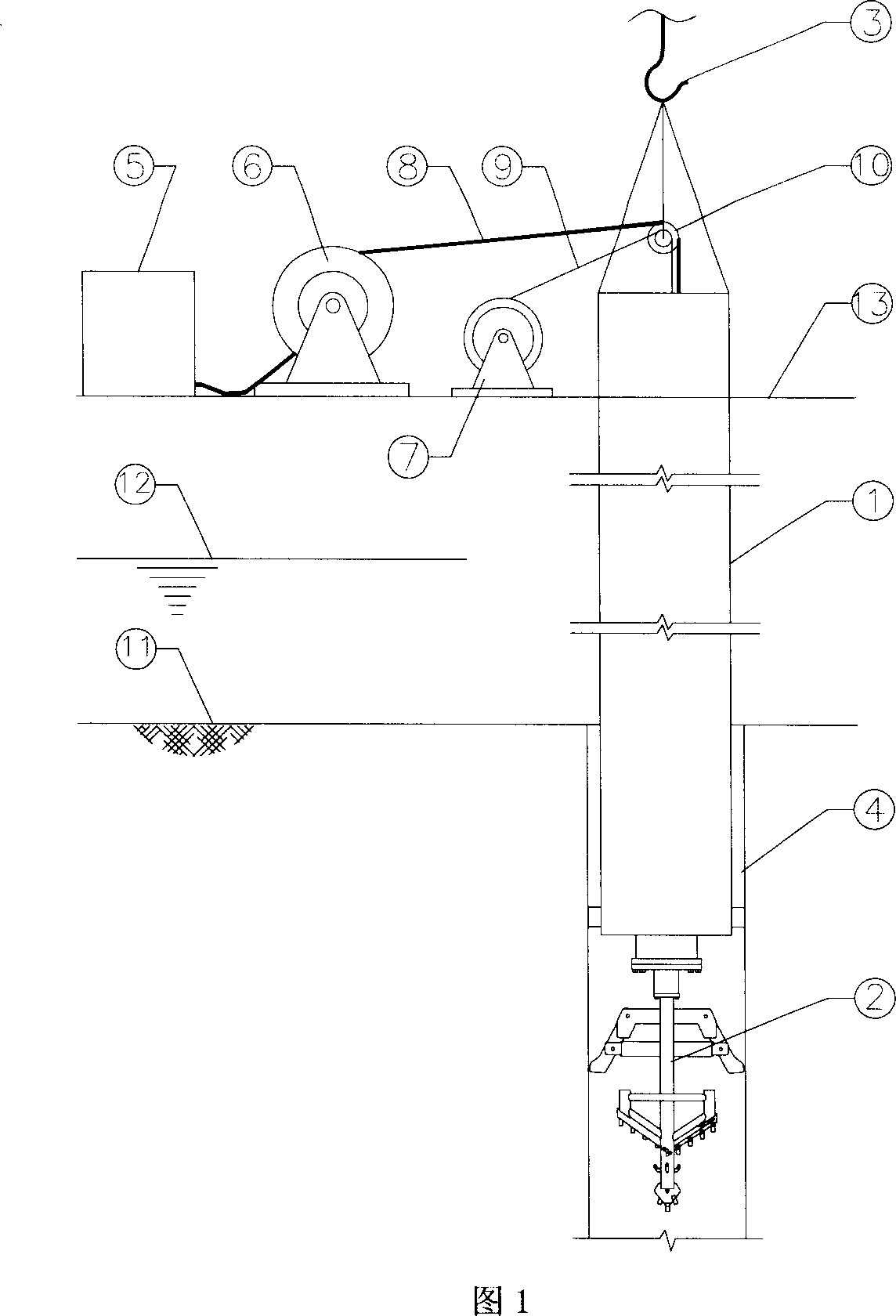

[0010] As shown in Figures 1-3, the means for carrying out the method reflected in the invention are illustrated by reference numerals. The waterproof casing (1) is suspended on the hook (3) of the platform drilling (workover) rig. In order to facilitate the installation and use of drilling tools, grout return and grouting, the lower end and outer wall of the riser need special treatment or additional pipelines. Four longitudinally evenly distributed torsion-limiting strips (18) and a limiting ring (19) are arranged on the inner wall of the lower end of the water-resistant casing (1) to resist the rotational torque of the drilling tool placed therein, and limit the rotation torque of the drilling tool in the water-resistant casing. The lowest position in the pipe; the outer wall of the lower end of the waterproof sleeve (1) is provided with a retaining ring (17), an inflation pipe (20), an air-dispersing ring pipe (21) and a grouting pipe (22), and the retaining ring (17) has ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com