Column-shape magnetron sputtering equipment

A sputter and columnar technology is applied in the field of magnetron sputtering, which can solve the problems of affecting the utilization rate of cylindrical magnetron sputtering equipment, unable to ensure long-term stable operation of the sputter, and restricting the application of cylindrical magnetron sputtering, etc. Achieve the effect of weakening the end effect, easy installation and general use, and convenient magnetic field arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

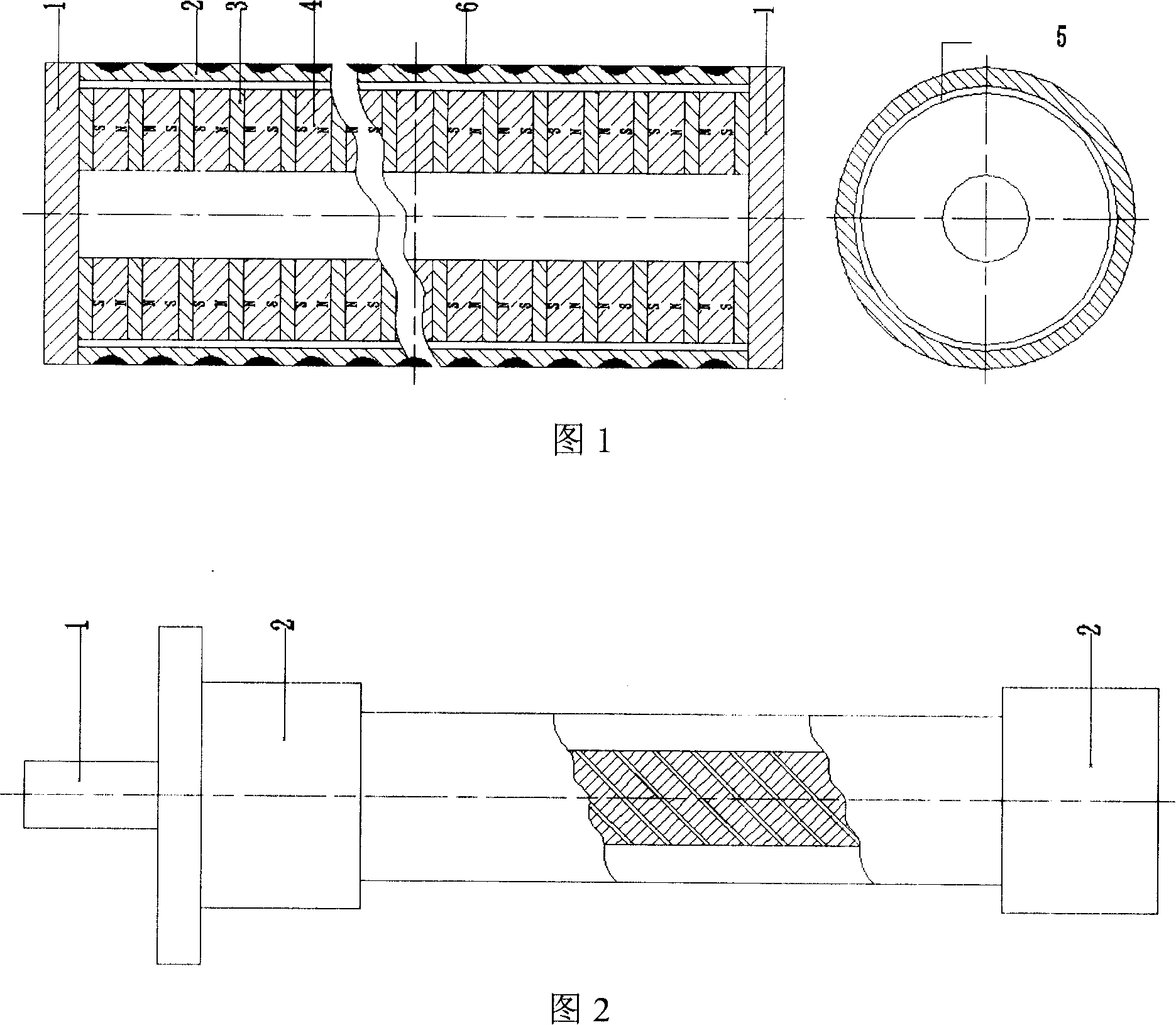

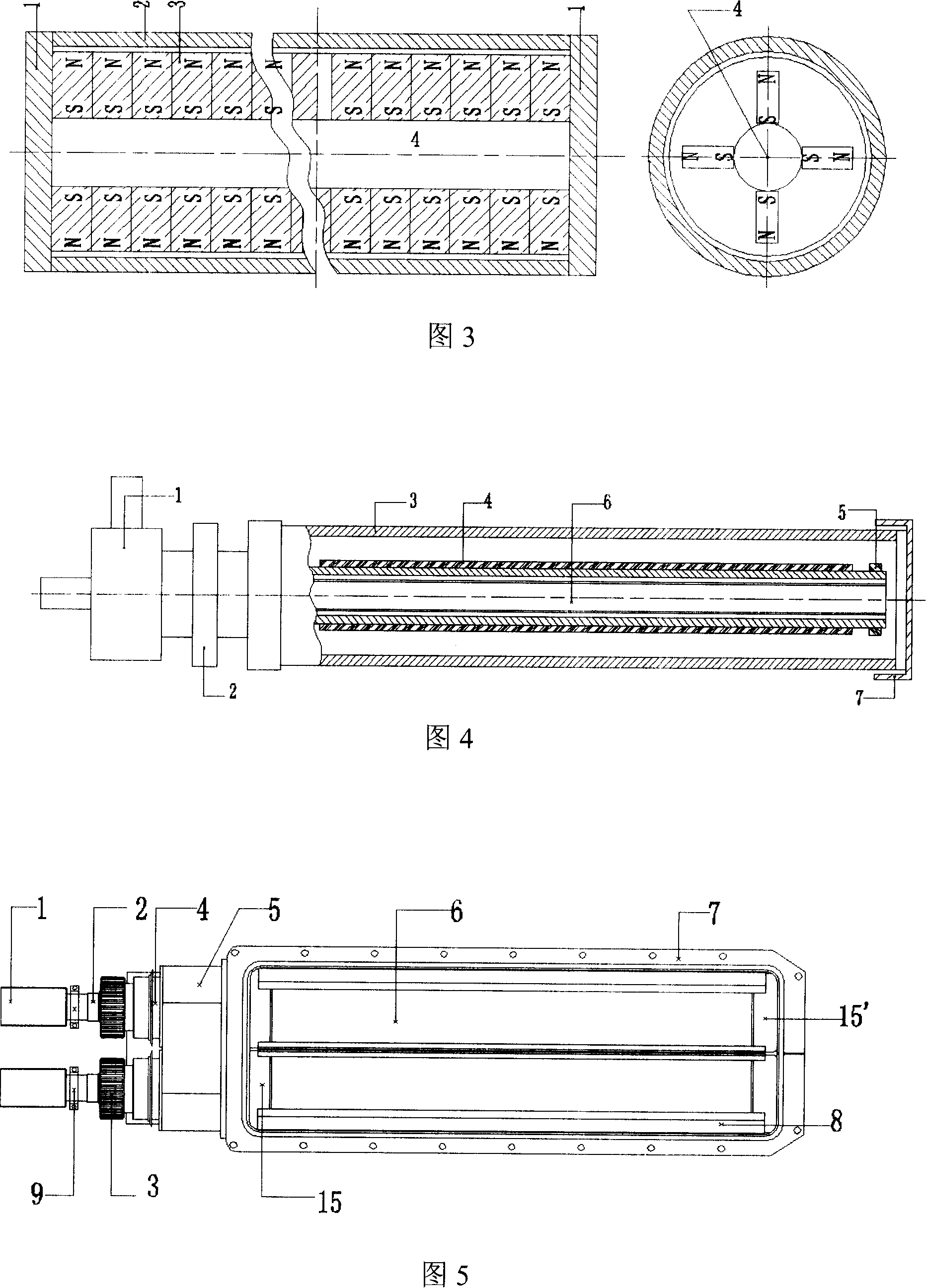

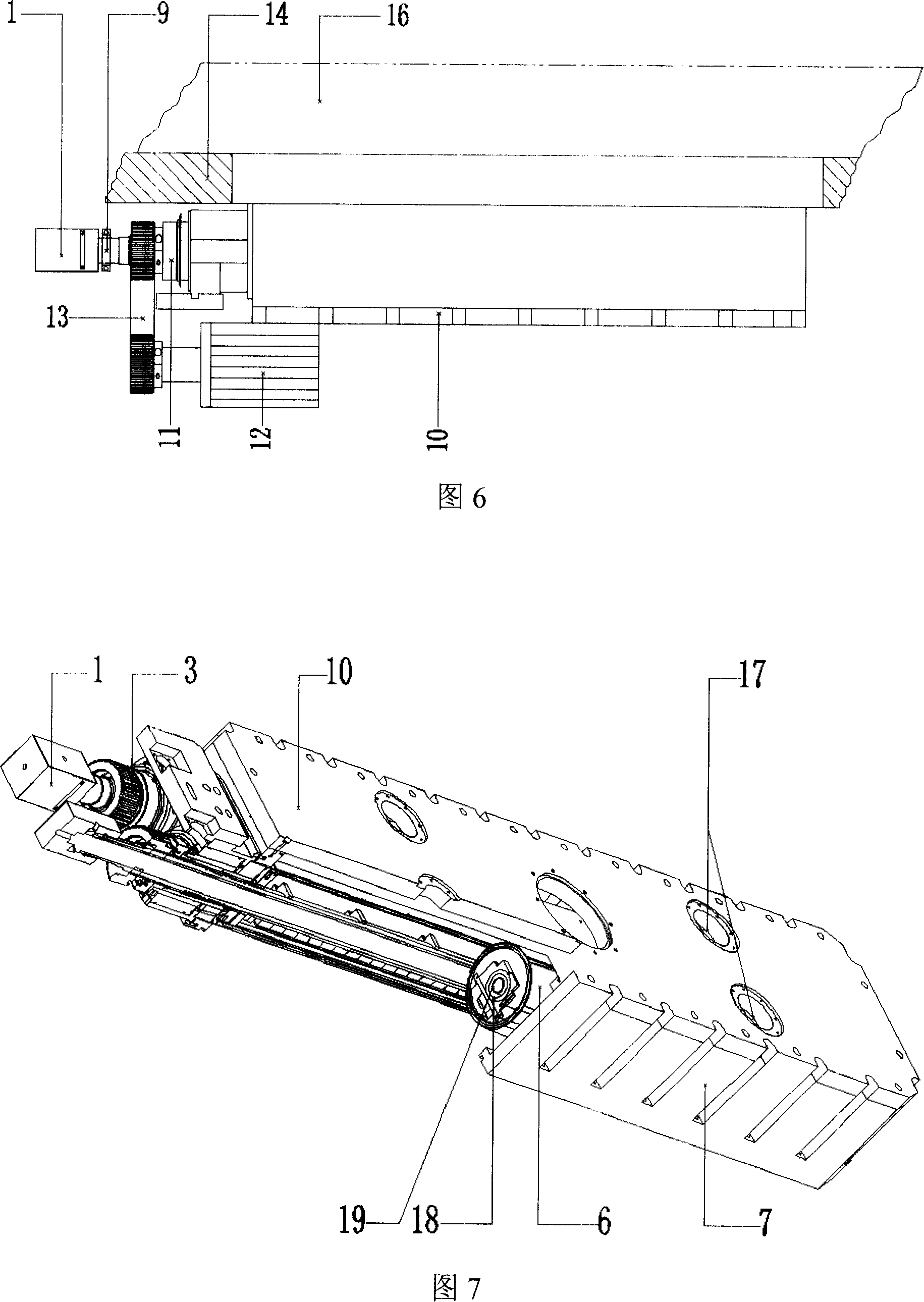

[0043] A closed columnar magnetron sputtering device, see Fig. 5-Fig. 13, includes a rotating water base 1, a rotating shaft 2, a synchronous wheel 3, a magnetic fluid device 4, a sputtering rotating base 5, a target cylinder (with a tubular target Material) 6, sputter base 7, shielding cover 8, spindle clamp 9, rear sealing plate 10, brush ring 11, frequency conversion motor 12, timing belt 13, sputter mounting seat 14, magnetic pole device 20, cooling Water conduit 19, gas distribution introduction hole 17, sputtering working chamber 15, main shaft 18 and upper and lower sealing end caps (15, 15') of the target cylinder.

[0044]Referring to Fig. 5-Fig. 8, a pair of target cylinder 6 and magnetic pole arrangement 20 (seeing Fig. 7 and Fig. 8) with tubular target material are installed in the sputter base 7, and the target cylinder 6 facing away from the magnetic pole arrangement 20 Shielding cover 8 is installed on the side. The synchronous wheel 3 and the rotating shaft 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com