An evaporation cavity heat radiator

A radiator and steam chamber technology, which is applied in the direction of instruments, instrument cooling, instrument parts, etc., can solve problems such as the inability of heat energy to dissipate rapidly, the infiltration of heat dissipation liquid, and the inability to accommodate too much heat dissipation liquid in the capillary space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

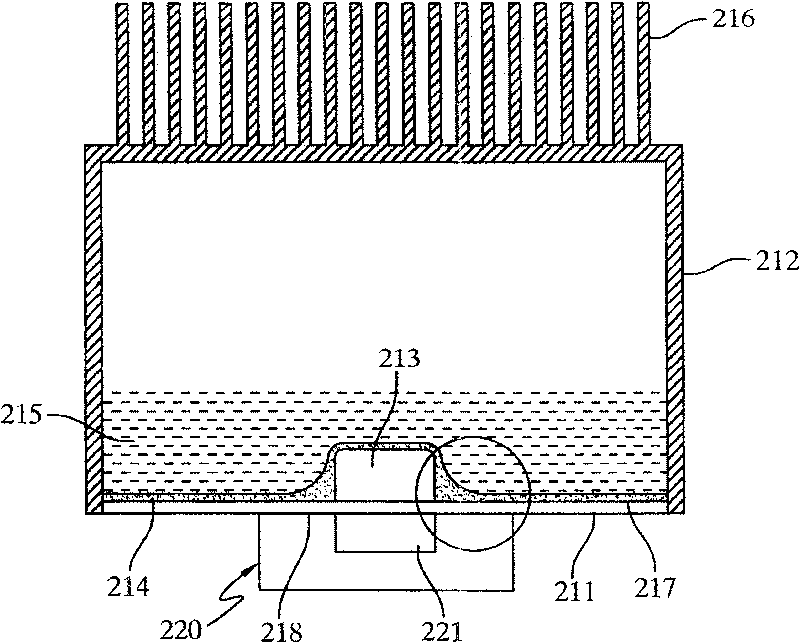

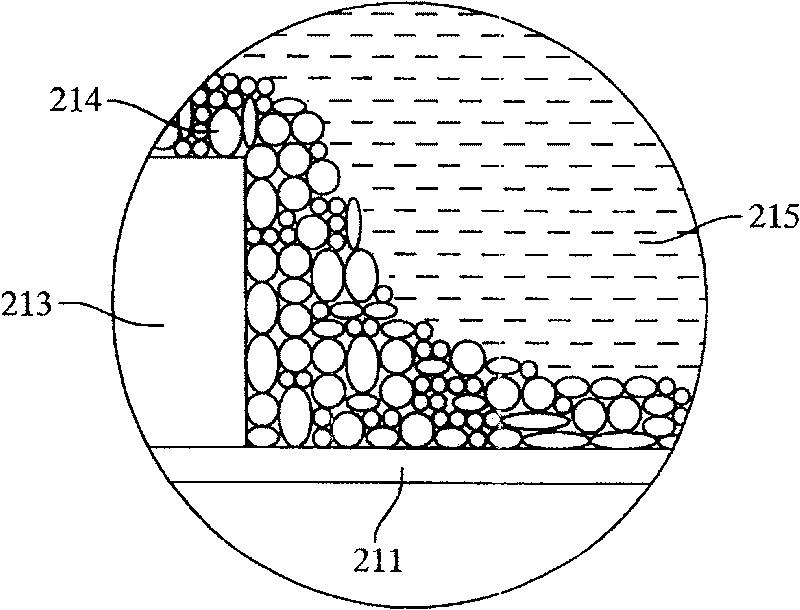

[0042] Please refer to Figure 2A and Figure 2B , which is a schematic structural diagram of the radiator and a detailed diagram of some components in the first embodiment of the present invention, which mainly includes a heat dissipation base 211, a cover body 212, a raised portion 213, a heat conduction powder 214, a heat dissipation liquid 215 and a plurality of fins 216, while the outside has a heating element 220, and the heating element 220 has a heating portion 221 that can generate heat energy.

[0043] Wherein, the heat dissipating base 211 has a base veneer 218 for bonding the heating element 220 and an inner surface 217 facing the accommodating space, and the inner surface 217 is provided with a protrusion 213 corresponding to the base veneer 218 . Moreover, when the heat dissipation base 211 is engaged with the cover body 212 , an airtight accommodating space is formed therebetween for accommodating the heat dissipation liquid 215 . And the heat conduction powde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com