Dual-side luminescent type organic LED and its making method

A light-emitting diode, double-sided light-emitting technology, used in semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc., can solve problems such as poor penetration of transparent electrodes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

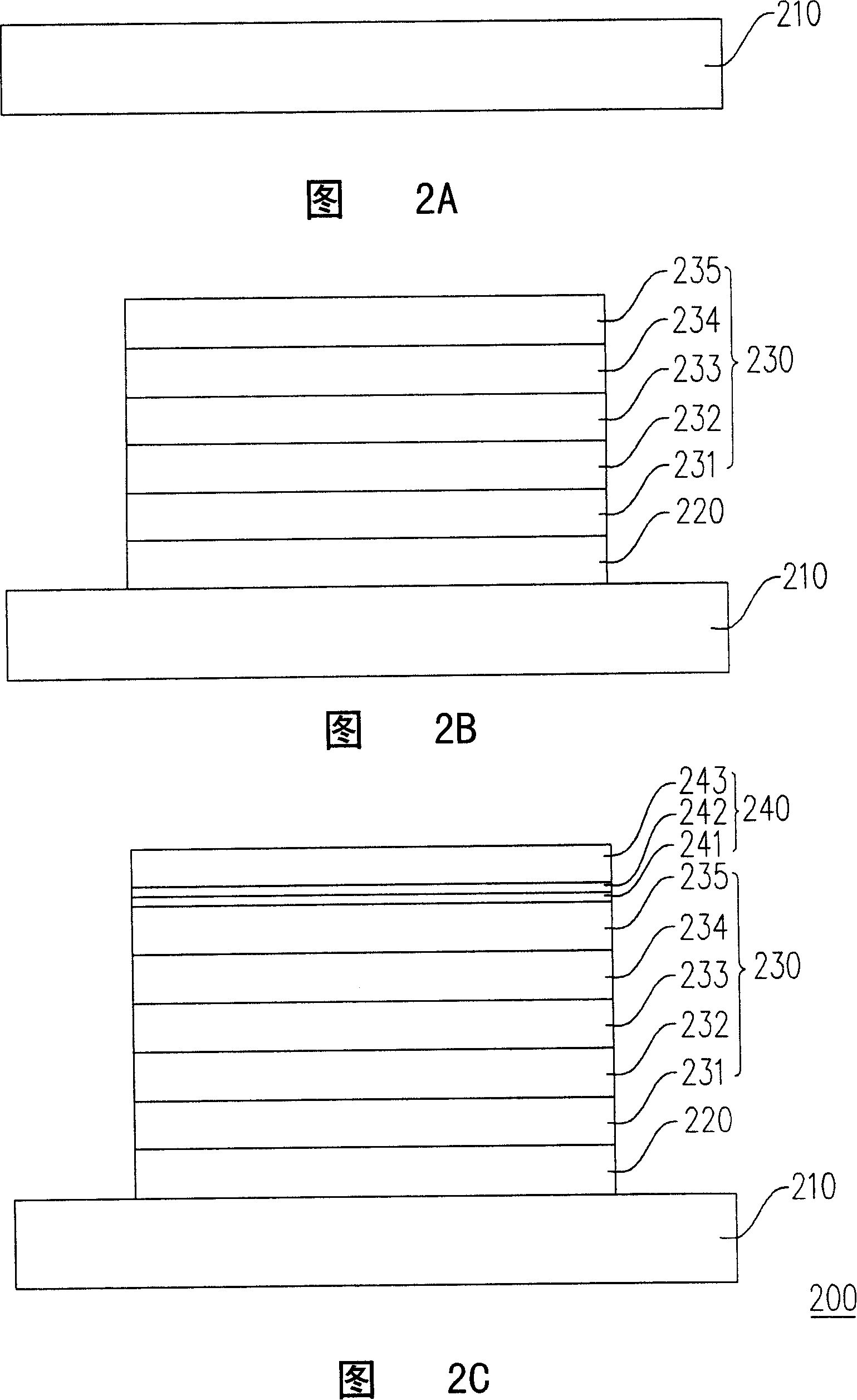

[0040]2A to 2C are cross-sectional schematic diagrams of the manufacturing process of a double-sided light-emitting organic light-emitting diode in a preferred embodiment of the present invention. First, please refer to FIG. 2A , a transparent substrate 210 is provided. In an embodiment of the present invention, the transparent substrate 210 may be a glass substrate or a substrate made of other suitable transparent materials. Next, please refer to FIG. 2B , a first transparent electrode 220 and an organic light emitting layer 230 are sequentially formed on the transparent substrate 210 . Generally speaking, the material of the first transparent electrode 220 can be indium tin oxide, indium zinc oxide, aluminum zinc oxide, antimony tin oxide, zinc oxide, indium oxide or tin oxide. In addition, in an embodiment of the present invention, the manufacturing method of the organic light-emitting layer 230 includes the following steps: firstly, a layer of hole injection layer 231 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com