Hollow compound insulator for 1100kV combined electrical appliance and its making method

A technology of composite insulators and combined electrical appliances, applied in insulators, lead-in/through-type insulators, circuits, etc., can solve the problems of low yield of large-scale porcelain sleeves, easy damage to other equipment, complicated firing process, etc., and achieve reliable performance. , The effect of uniform laying and high connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1

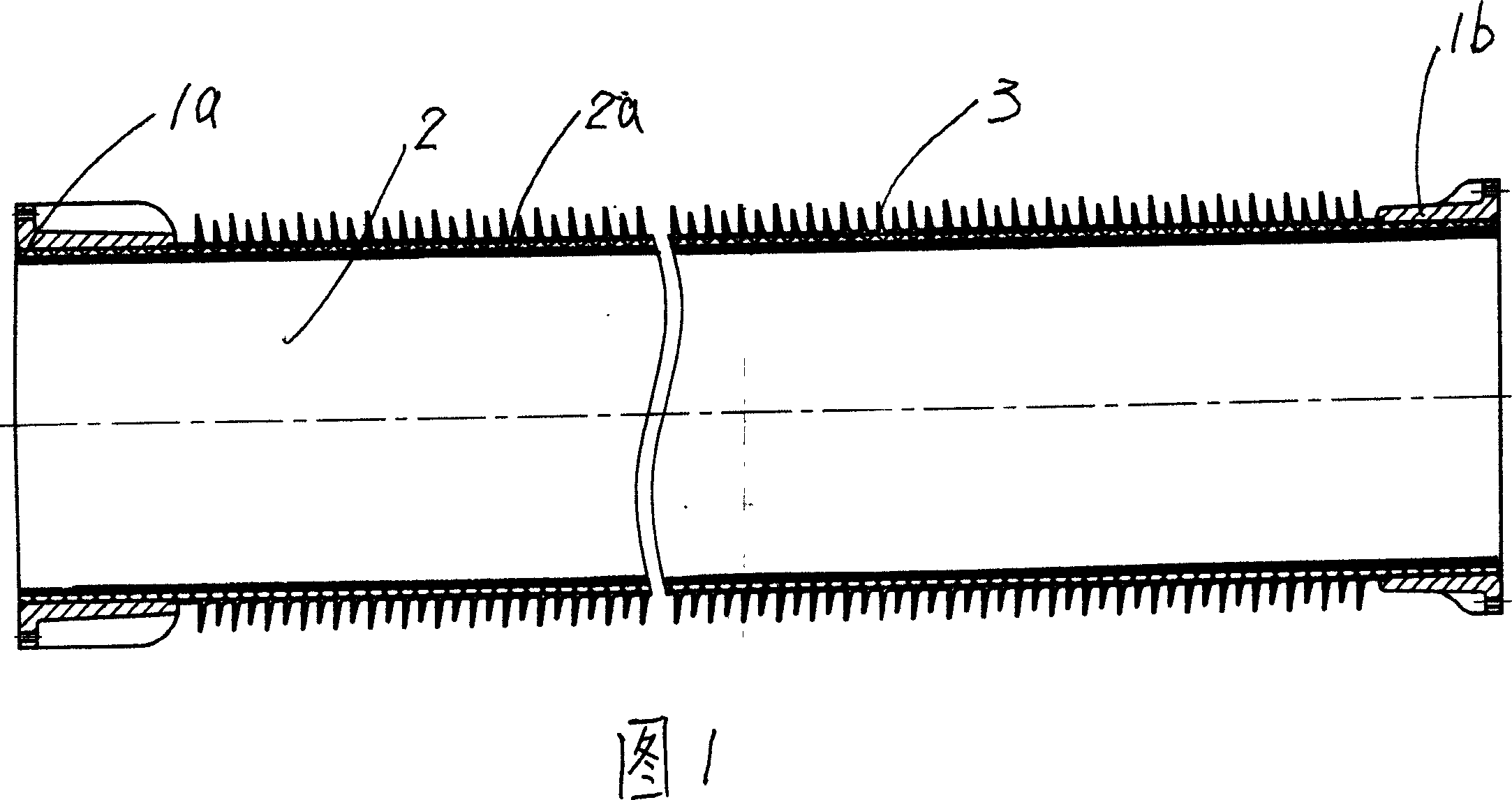

[0037] The umbrella body 3 is made of high-temperature vulcanized silicone rubber, and its components by weight are: 25% methyl vinyl silicone rubber, 35% white carbon black, 35% aluminum hydroxide, 4% silicone oil, and 1% vulcanizing agent.

[0038] Manufacturing steps:

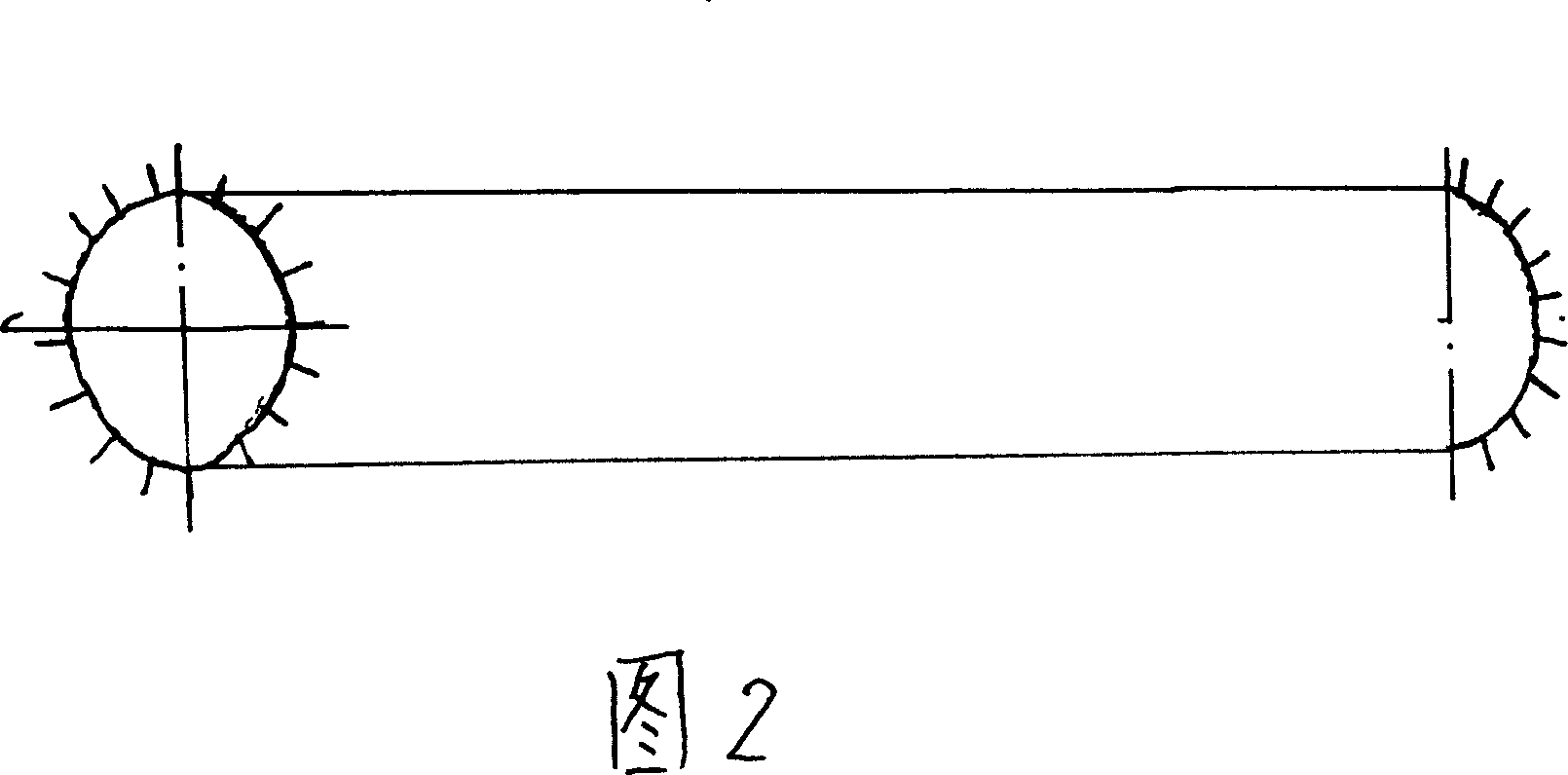

[0039] ① On the mold core of the insulating tube 2 to be wound, fix pins at both ends of the axis of the simulated trajectory;

[0040] ②Apply epoxy resin glue and SF evenly on the mold core of the insulating tube 2 to be wound 6 A mixture of decomposed products to form the lining layer 2a;

[0041] ③ On the basis of step ②, the glass fiber yarn impregnated with epoxy resin glue is evenly wound on the mold core through a constant tension control mechanism to form a hollow tube body to a preset thickness;

[0042] ④ curing the hollow tube made in step ③ at high temperature;

[0043] ⑤ Machining the hollow tube made in step ④ to make the insulating tube 2;

[0044] ⑥Apply the coupling agent evenly on the o...

manufacture example 2

[0052] The umbrella body 3 is made of high-temperature vulcanized silicone rubber, and its components by weight are: 30% methyl vinyl silicone rubber, 33% white carbon black, 33% aluminum hydroxide, 3% silicone oil, and 1% vulcanizing agent.

[0053] Manufacturing steps:

[0054] ① On the mold core of the insulating tube 2 to be wound, fix pins at both ends of the axis of the simulated trajectory;

[0055] ②Apply epoxy resin glue and SF evenly on the mold core of the insulating tube 2 to be wound 6 A mixture of decomposed products to form the lining layer 2a;

[0056] ③ On the basis of step ②, the glass fiber yarn impregnated with epoxy resin glue is evenly wound on the mold core through a constant tension control mechanism to form a hollow tube body to a preset thickness;

[0057] ④ curing the hollow tube made in step ③ at high temperature;

[0058] ⑤ Machining the hollow tube made in step ④ to make the insulating tube 2;

[0059]⑥Apply the coupling agent evenly on the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com