Full-degradation lactic acid polymer spun-bonded continuous yarn non-woven fabrics and preparation method thereof

A technology of lactic acid polymer and filament non-woven fabric, which is applied in the direction of single-component polyester artificial filament, filament molding treatment, and melting of filament raw materials, which can solve the problem of high cost, impossible preparation of polylactic acid fiber, Inability to adapt to issues such as affordability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

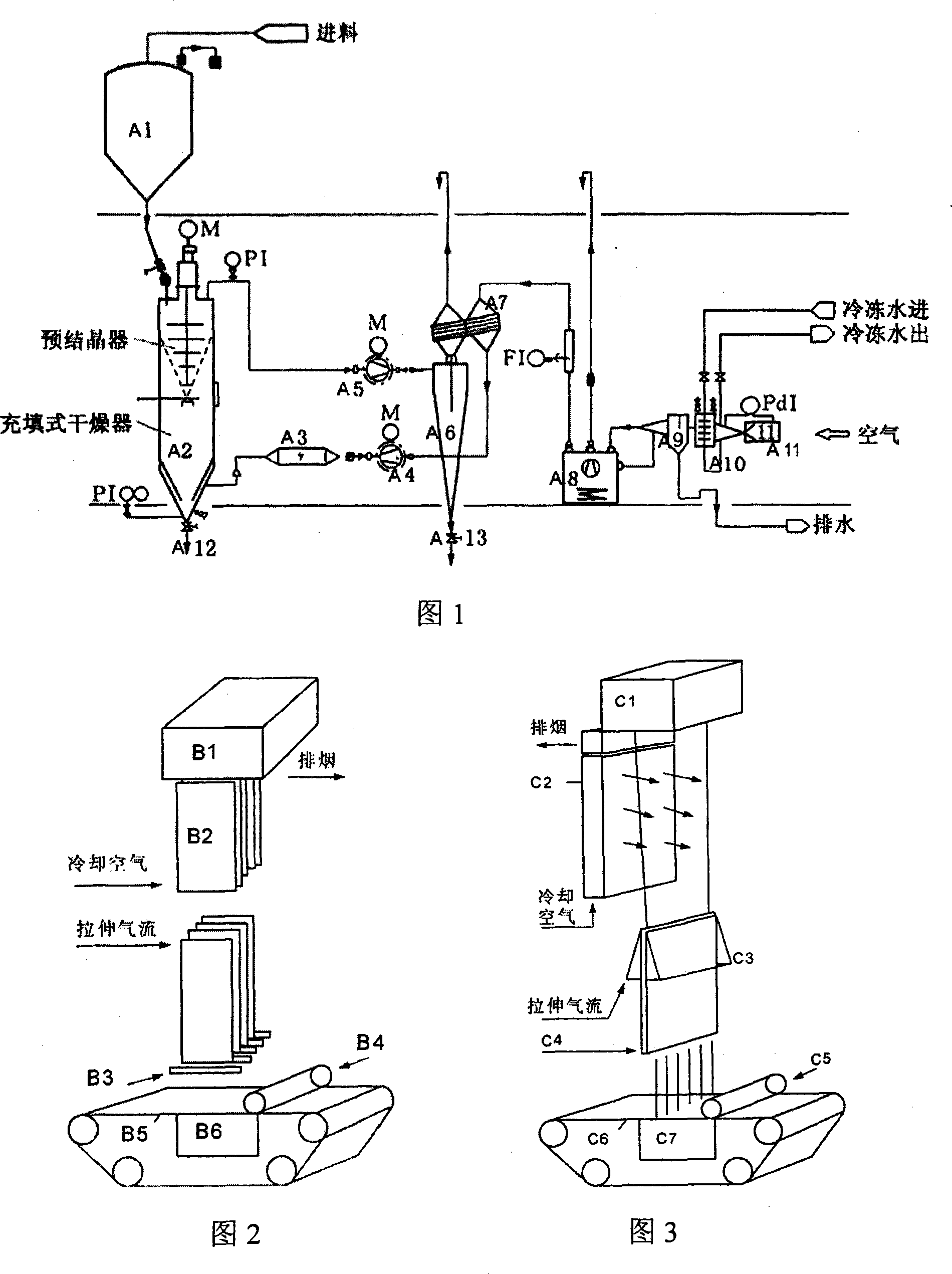

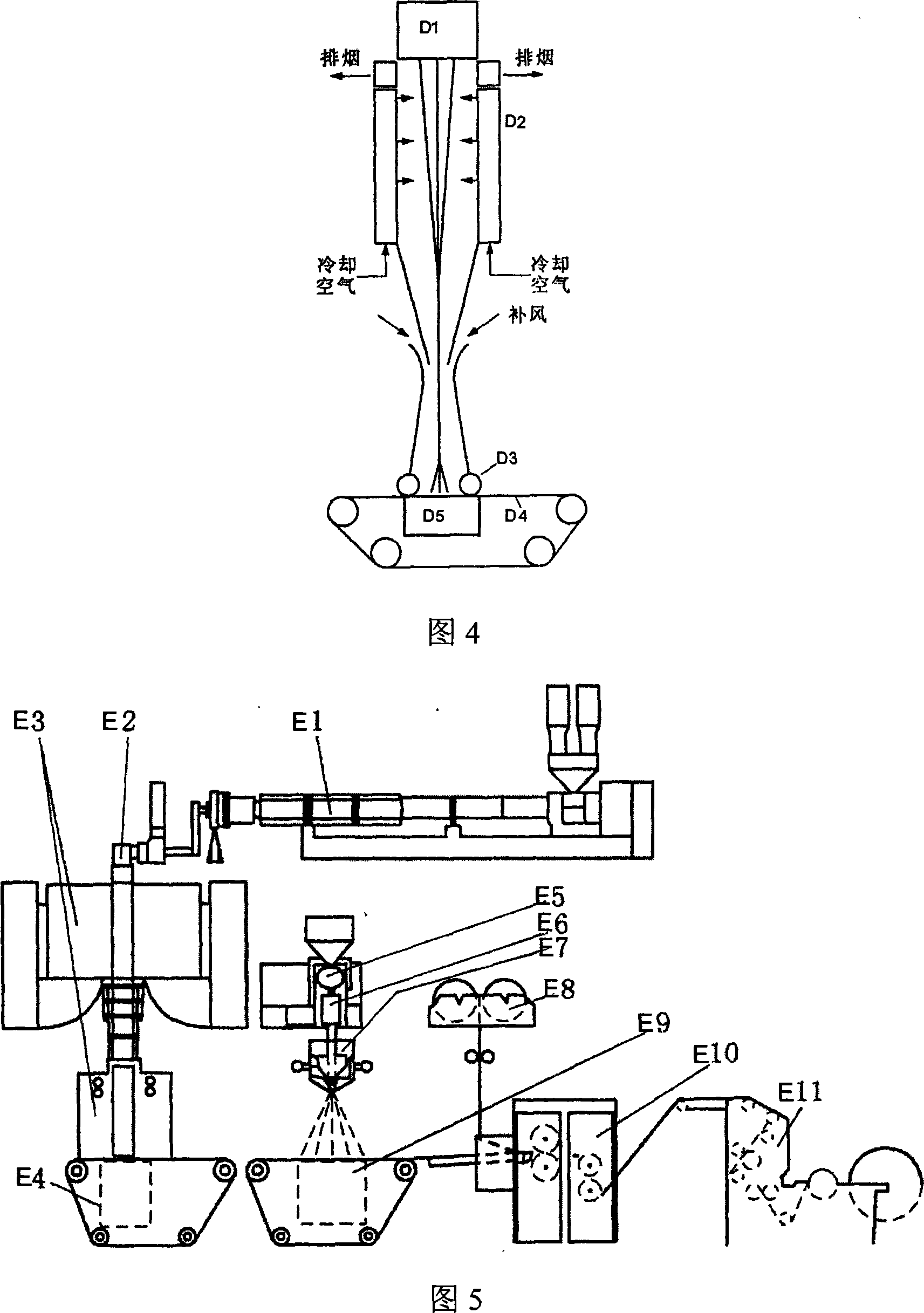

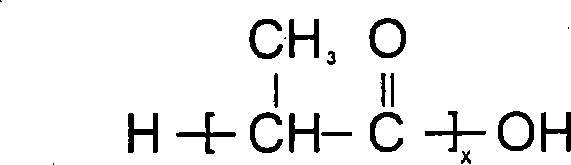

Method used

Image

Examples

Embodiment 1

[0040]Polylactic acid (PLA) slices (molecular weight of 100,000, melt index of 20-25, melting point of 180°C, thermal cracking temperature of 300°C) are fully dried through continuous drying equipment, and the slices are sucked from the trough to the The pre-spinning hopper, the feeding process is intermittent automatic feeding. Chips fall from the pre-spinning hopper into the screw extruder by its own weight, and the sleeve of the extruder is heated in different regions. The slices are extruded and melted in the extruder, then enter the continuous pre-filter, and then enter the spinning box. The melt enters the spinning head through the metering pump, and is accurately metered by the metering pump, and the melt is quantitatively transported to the spinneret, and forms a continuous melt stream through the 0.2mm spinneret hole, that is, the primary fiber. The screw extrusion temperature is 180°C, the box temperature is 160-220°C, the spinning speed is 800m / min, and the as-spun...

Embodiment 2

[0042] Fully dry polylactic acid (PLA) slices (molecular weight 130,000, melt index 20-25, melting point 170°C, thermal cracking temperature 280°C) through continuous drying equipment, and the slices are sucked from the trough to the The pre-spinning hopper, the feeding process is intermittent automatic feeding. Chips fall from the pre-spinning hopper into the screw extruder by its own weight, and the sleeve of the extruder is heated in different regions. The slices are extruded and melted in the extruder, then enter the continuous pre-filter, and then enter the spinning box. The melt enters the spinning head through the metering pump, and is accurately metered by the metering pump, and the melt is quantitatively transported to the spinneret, and forms a continuous stream of melt through the 1mm spinneret hole, that is, the primary fiber. The extrusion temperature of the screw is 150°C, the temperature of the box is 160-220°C, the spinning speed is 550m / min, and the as-spun f...

Embodiment 3

[0044] Polylactic acid (PLA) slices (molecular weight 80,000, melt index 20-25, melting point 200°C, thermal cracking temperature 350°C) are fully dried through continuous drying equipment, and the slices are sucked from the trough to the spinning machine by a fan. The front hopper, the feeding process is intermittent automatic feeding. Chips fall from the pre-spinning hopper into the screw extruder by its own weight, and the sleeve of the extruder is heated in different regions. The slices are extruded and melted in the extruder, then enter the continuous pre-filter, and then enter the spinning box. The melt enters the spinning head through the metering pump, and is accurately metered by the metering pump, and the melt is quantitatively transported to the spinneret, and forms a continuous stream of melt through the 0.3mm spinneret hole, that is, the primary fiber. The extrusion temperature of the screw is 200°C, the temperature of the box is 160-220°C, the spinning speed is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| cracking temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com