Stretching core head for hollow metal pipe

A technology of hollow metal tubes and core heads, applied in the direction of the mandrel, etc., can solve the problems of poor internal and external surface quality, scrapping of drawing dies, high friction, etc., to improve service life and processing rate of drawing passes, and ensure dimensional accuracy , good lubricating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

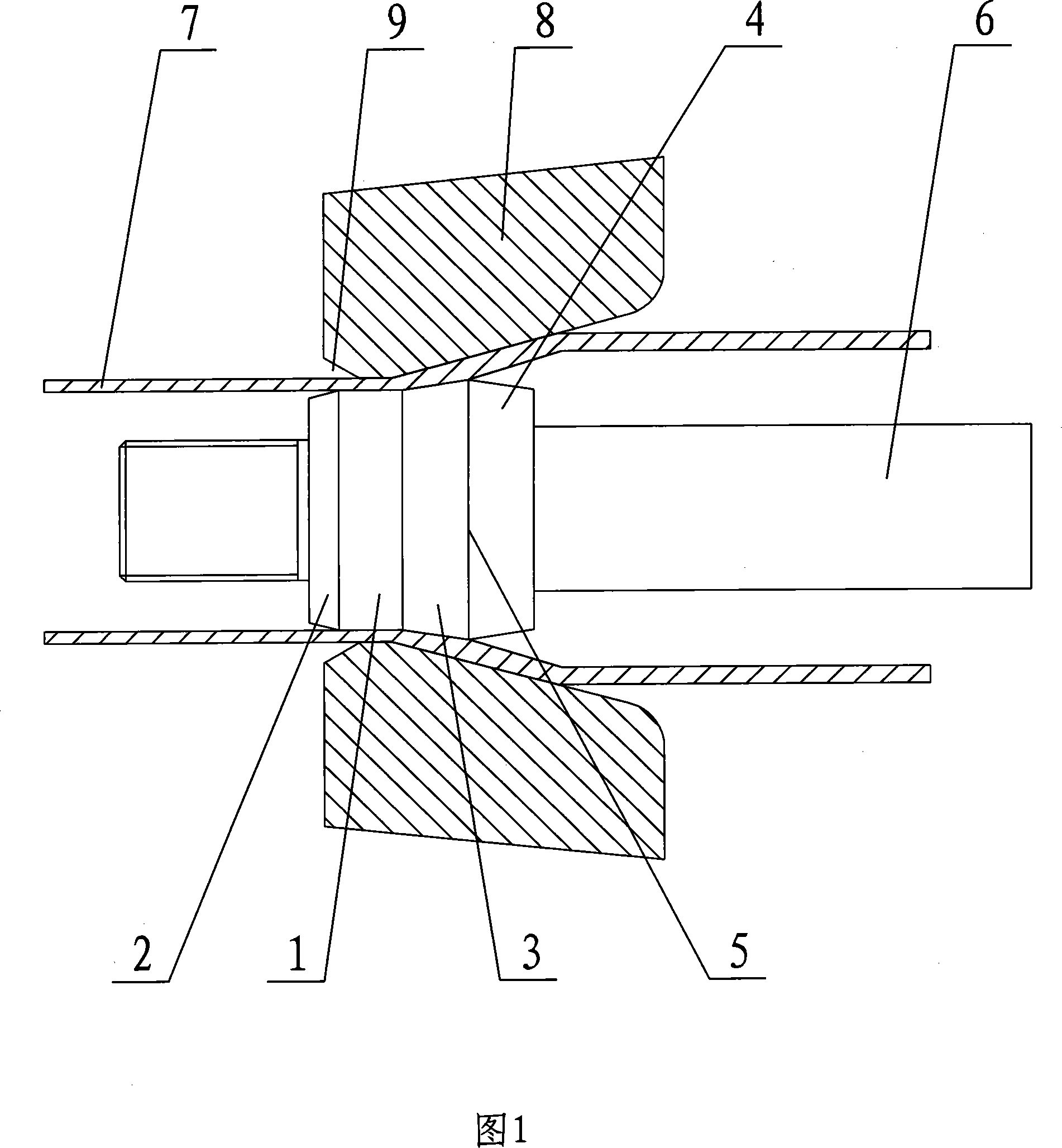

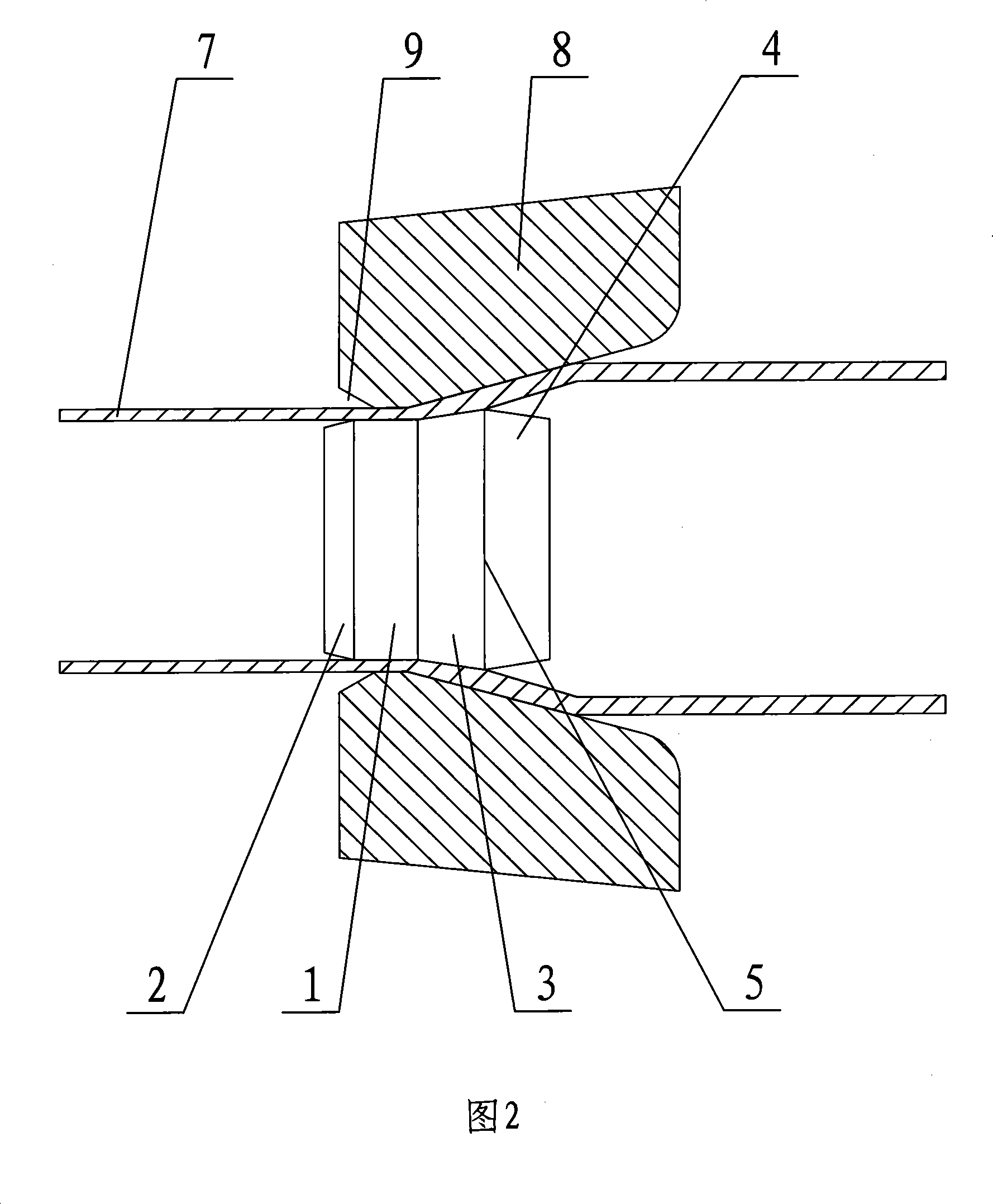

[0012] As shown in Figure 1, the drawing core 5 of the hollow metal pipe includes a sizing section 1, an outlet chamfering section 2 arranged on one side of the sizing section 1, and a Deformation section 3 inclined upwards. The sizing section 1 is conical with a certain taper, and the end close to the deformation section 3 is a large diameter end. On the other side of the deformation section 3 there is also an inlet chamfer section 4 .

[0013] The drawing core head 5 of the hollow metal pipe of the above structure is used for the working process of straight drawing: firstly, the drawing core head 5 of the hollow metal pipe is fixed on the core rod 6, and is inserted into the hollow metal pipe 7 with a collet. Inject lubricating oil, then put the hollow metal pipe 7 on the core rod 6, put the chuck end of the hollow metal pipe 7 into the drawing outer mold 8, and place it 30-60mm behind the drawing core 5 of the hollow metal pipe The hollow metal pipe 7 is pitted, and then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com