Heat expansion valve

A thermal expansion valve and valve core technology, applied in the field of thermal expansion valves, can solve the problems of complex assembly, many parts, high cost, etc., and achieve the effect of simple assembly operation, reducing the increase in the number of parts, and reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Specific embodiments of the present invention will be described below with reference to the drawings.

[0021] Since the basic structure of the thermal expansion valve of the present invention is the same as that of the previous patent document 2, it will not be repeated here.

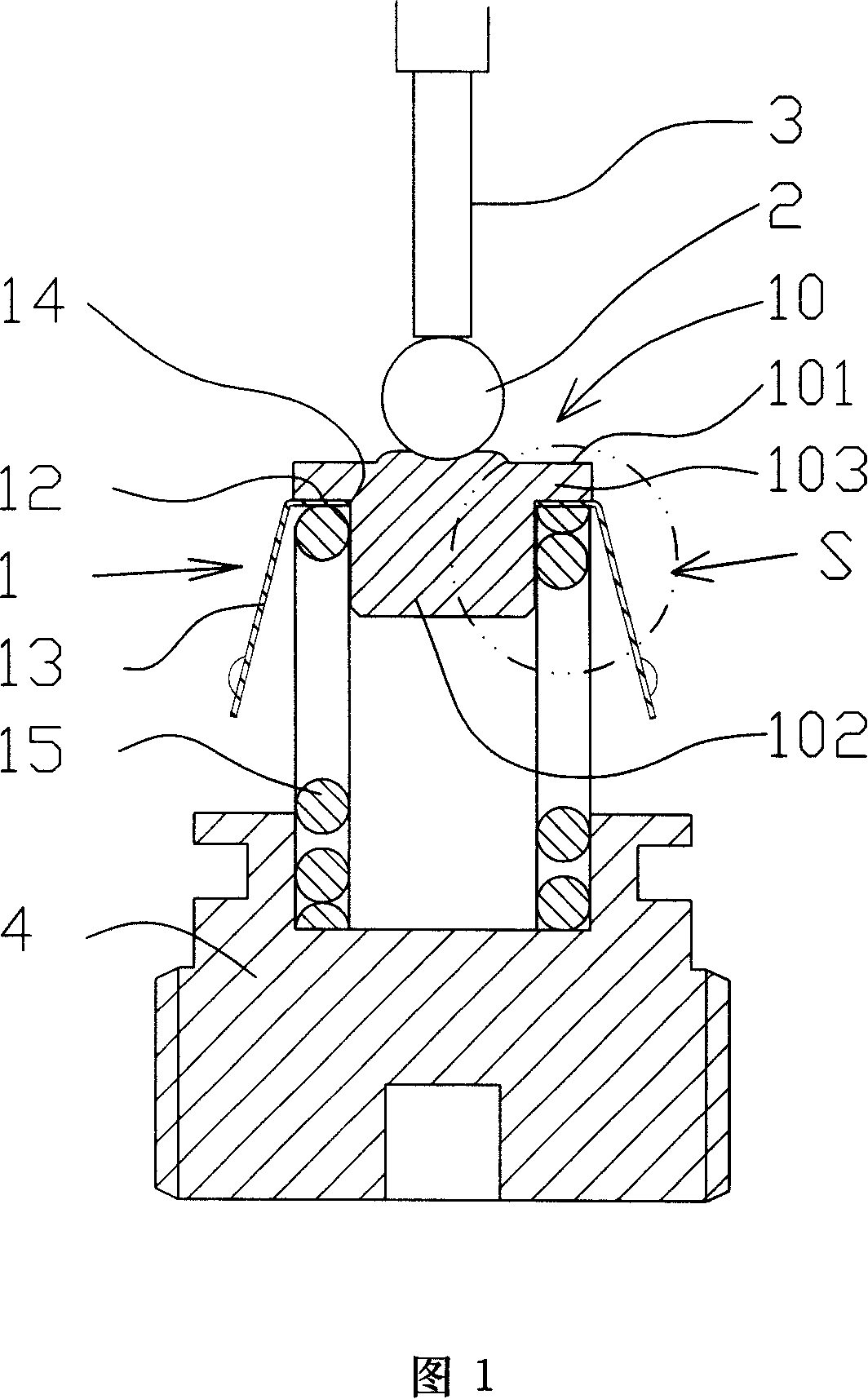

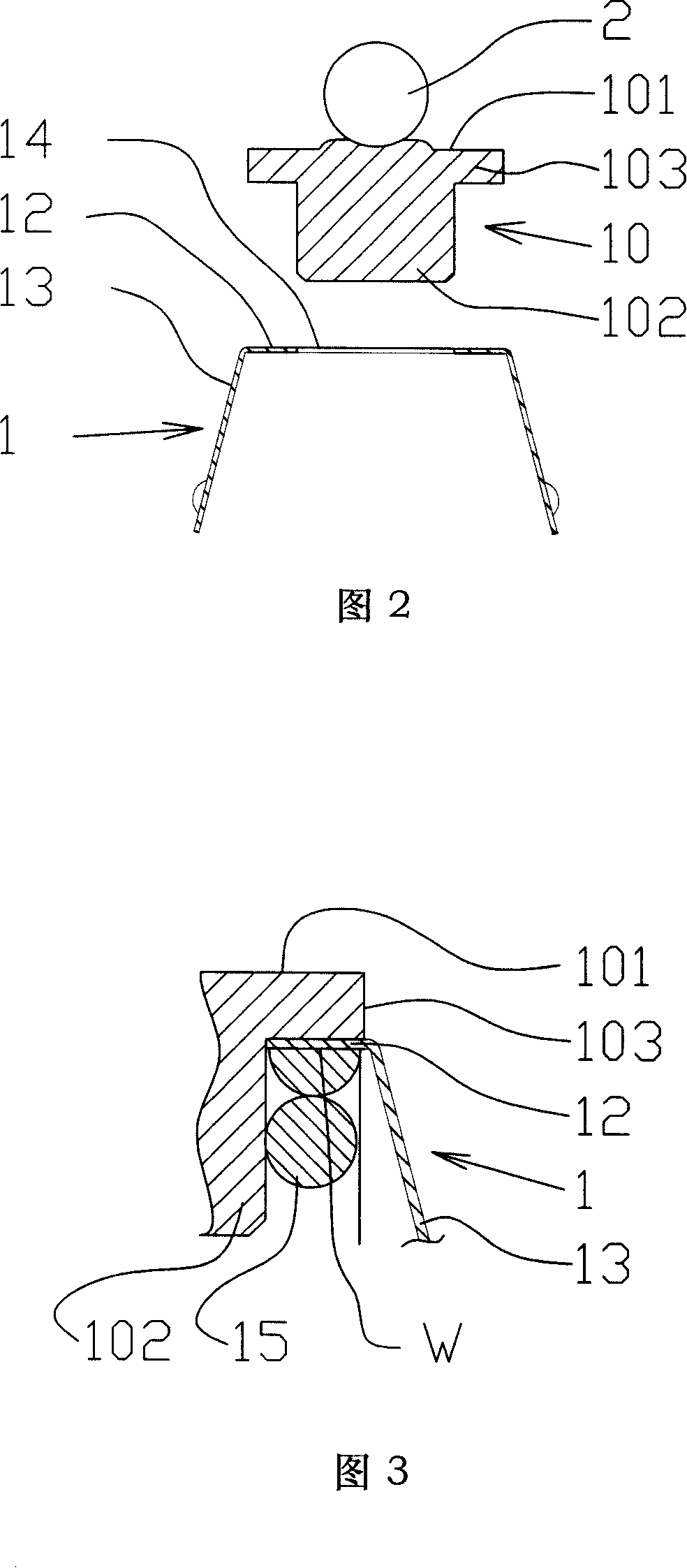

[0022] The components for preventing movement of the spool will be described with reference to FIG. 1 , FIG. 2 and FIG. 3 .

[0023] First of all, the thermal expansion valve is mainly composed of the following structure: the orifice formed between the high-pressure flow path and the low-pressure flow path of the high-pressure refrigerant that flows into the evaporator in the valve body, and the orifice is opposite to the upstream side of the refrigerant at the above-mentioned orifice. The spool placed in the opposite direction, the spool frame that transmits the pre-tightening force of the compression spring to the spool, the air box head part that moves with the temperature of the low-pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com