Stitching type jaw single and bidirectional over running clutch

An overrunning clutch, one-way overrunning technology, applied in one-way clutches, clutches, mechanical equipment, etc., can solve the problems of insufficient size, collision transmission torque, no slippage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0093] Necessary note: In the text of this manual and all drawings, the same or similar components and their characteristic parts use the same symbols, so this manual only gives detailed descriptions when they appear for the first time, and will be used when they appear again later. No repeated elaboration will be given.

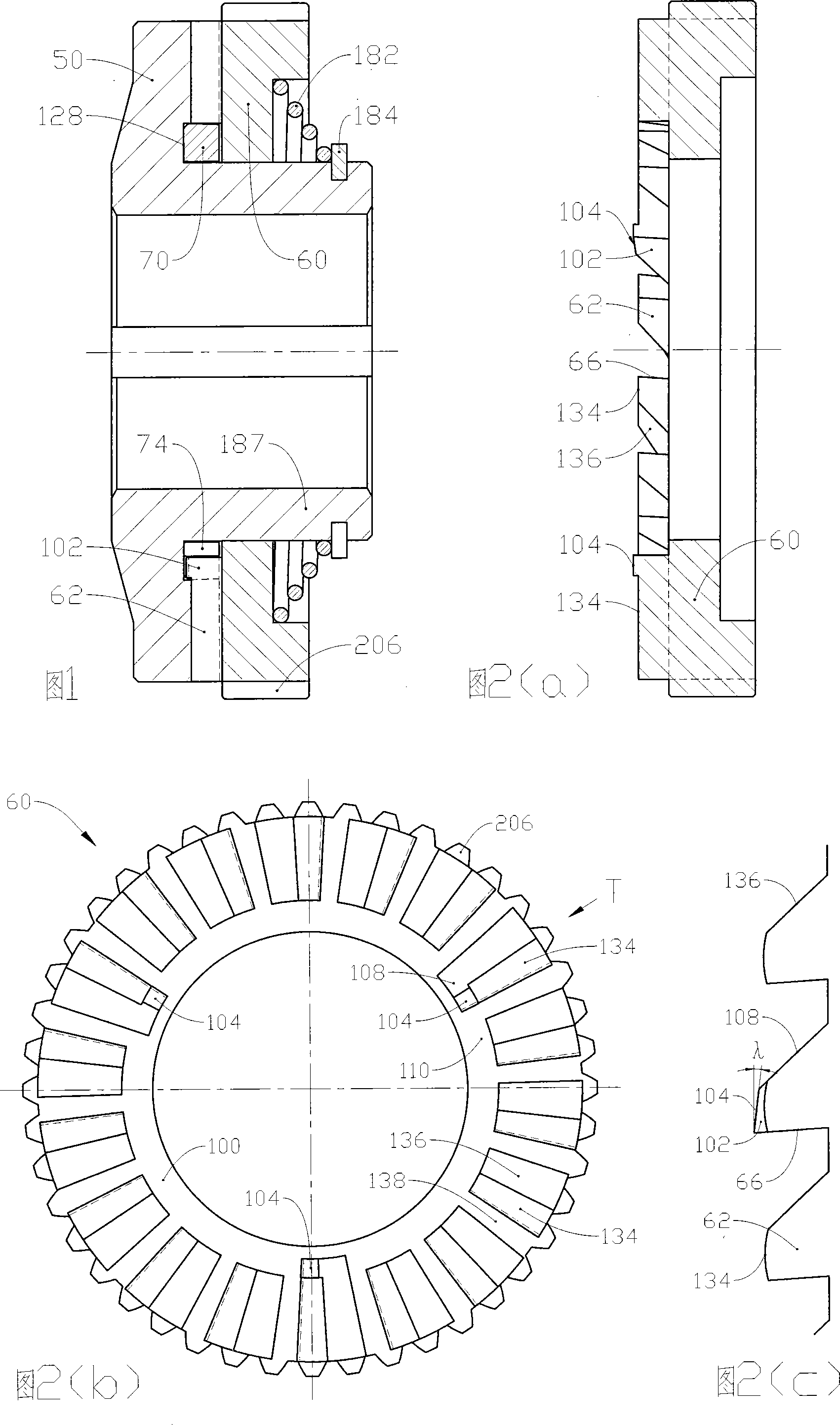

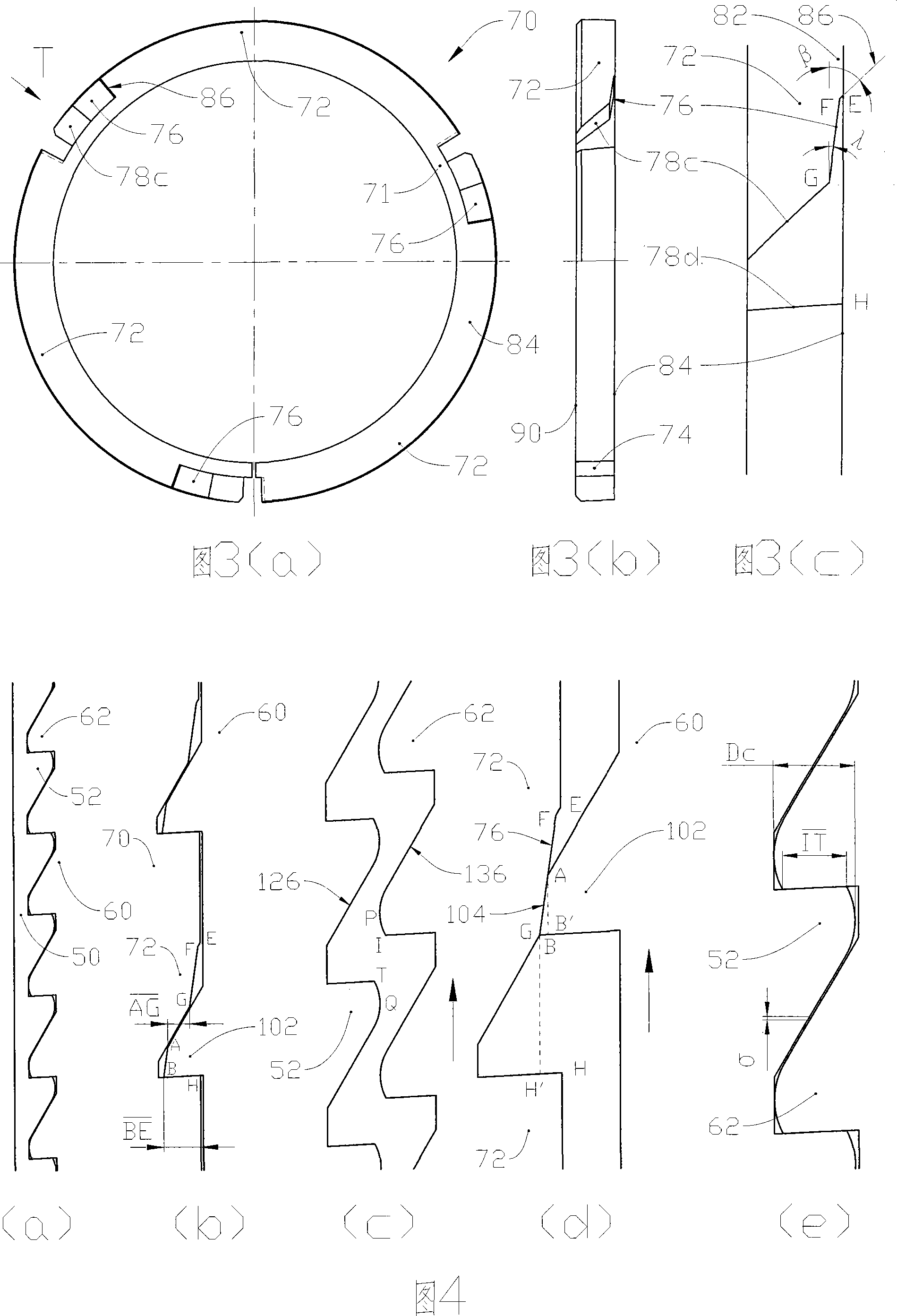

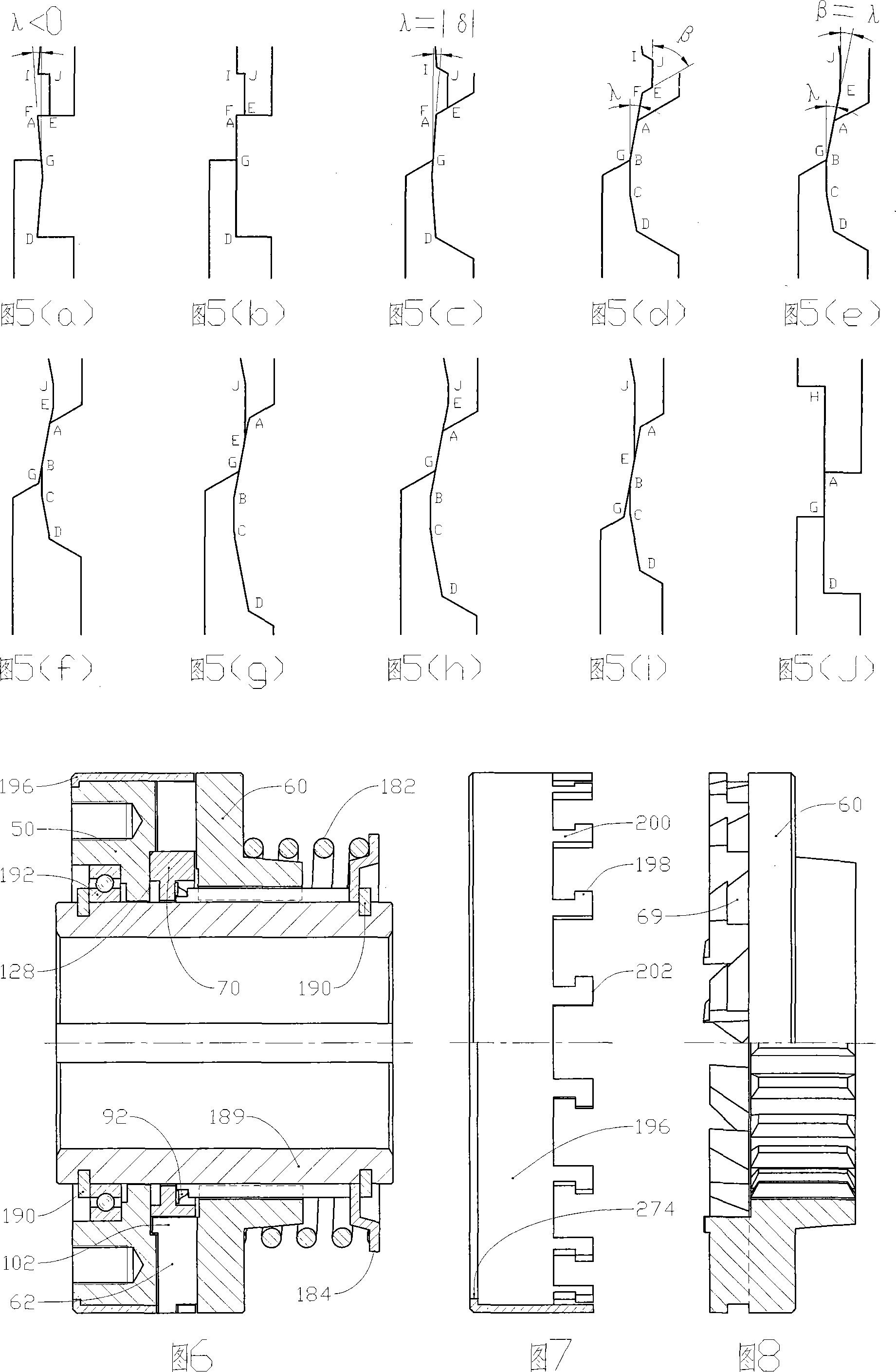

[0094] The simplest embodiment of the one-way overrunning clutch of the present invention is shown in Figures 1 to 4, which is in the form of wheel-shaft transmission. The first engaging element 50 is rigidly integrated with the first bushing 187 , and the second engaging element 60 is fitted on the first bushing 187 with its mating ends facing each other, and forms a working fitting mechanism with the first engaging element 50 . The gear teeth 206 are integrally formed on the outer cylindrical surface of the second engagement element 60 . The compression spring 182 is mounted between the non-fitting end surface of the second engaging element 60 and a sprin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com