Synchronous generator and method for constructing mutual feedback system of synchronous motor

A synchronous motor and synchronous generator technology, applied in motor generator control, motor/generator/inverter limiter, control system, etc., can solve the problems of wasting energy and high cost of reducer power-load test system, Achieve the effect of saving energy, novel design ideas, and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

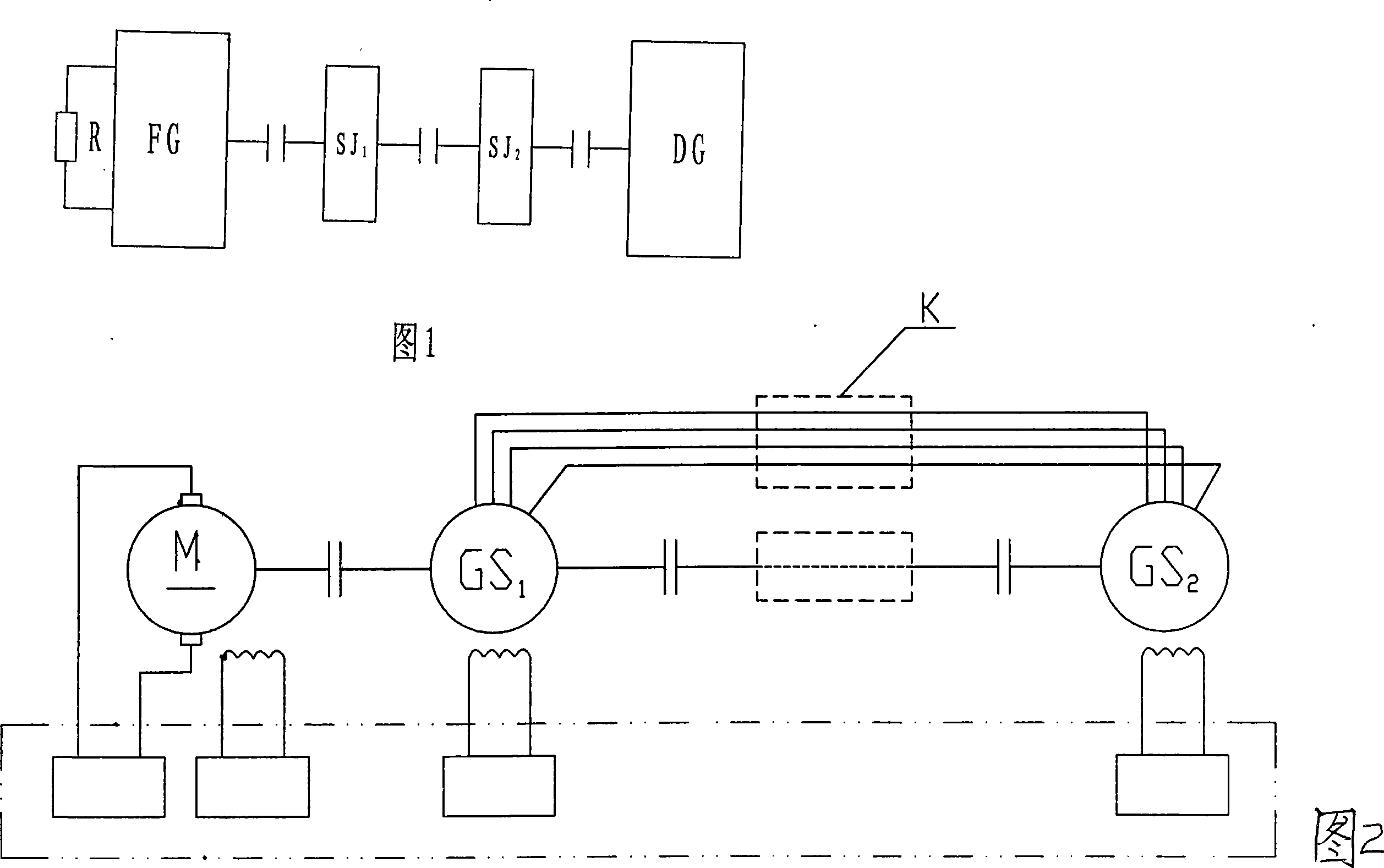

[0010] As shown in Figure 2, the construction method of the synchronous generator and synchronous motor mutual feed system, select two synchronous motors GS1 and GS2 with the same performance parameters (such as number of poles, rated voltage, etc.), and make one of the synchronous motors GS1 The stator can rotate relative to the rotor. The conventional method is to make the synchronous motor a biaxial extension and support the biaxial extension through the bearing; keep the mechanical phase of the rotor of the two synchronous motors (that is, the mechanical position of the rotor relative to the stator) the same In the case of coaxial connection; a motor M is coaxially connected with two synchronous motors (the motor M can be located on one side of a synchronous motor or between two synchronous motors. From the perspective of structural rationality, the motor M is usually located in a synchronous motor. One side of the synchronous motor); start the motor M to drive the two sync...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com