Konjak portuguese gansu polyose gel microsphere and method for preparing same

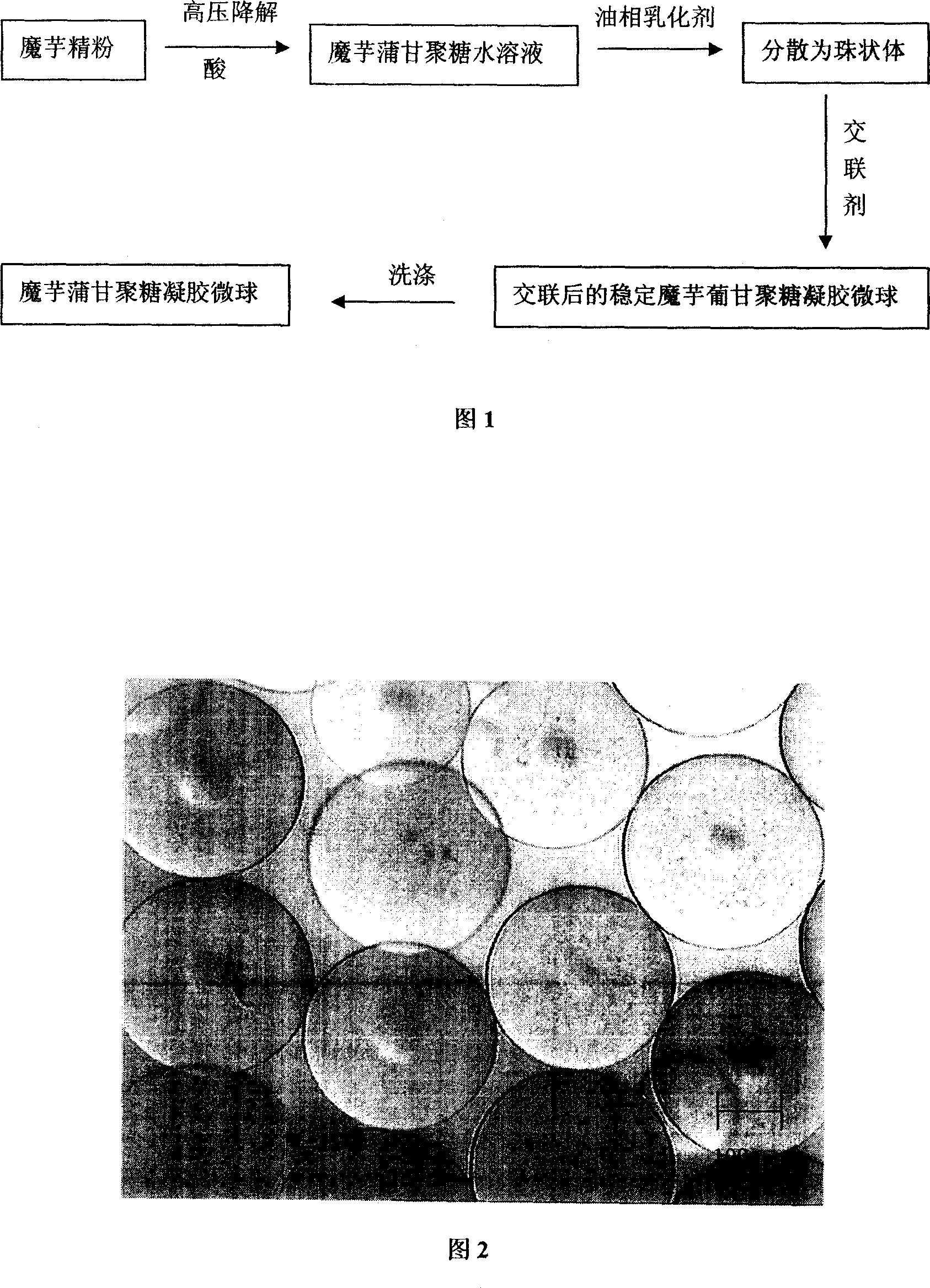

A technology of konjac glucomannan and gel microspheres, which is applied in the preparation of microspheres, microcapsule preparations, etc., can solve the problems of complex operation, strict requirements, and complex reaction equipment in the reaction process, and achieve simplified sphere-forming process steps, The effect of shortening the production cycle and expanding the separation range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Preparation of aqueous solution of konjac glucomannan.

[0035] In a 1000ml reactor, mix 45.6ml of 0.5M HCl and 272.7g of water evenly, pour 56.7084g of commercially available konjac fine powder into the mixture, and stir evenly. Seal the reactor, put it in an autoclave, and degrade it at 113°C for 40 minutes. After the degradation is complete, take out the reactor. After the temperature drops to room temperature, pour 125g of 40% NaOH into it to dissolve it. Yellow 10% solid content konjac glucomannan aqueous solution. According to this method, an aqueous solution of konjac glucomannan with a solid content of 6% and 15% can be prepared for future use.

Embodiment 2

[0037] Preparation of konjac glucomannan gel microspheres in xylene system.

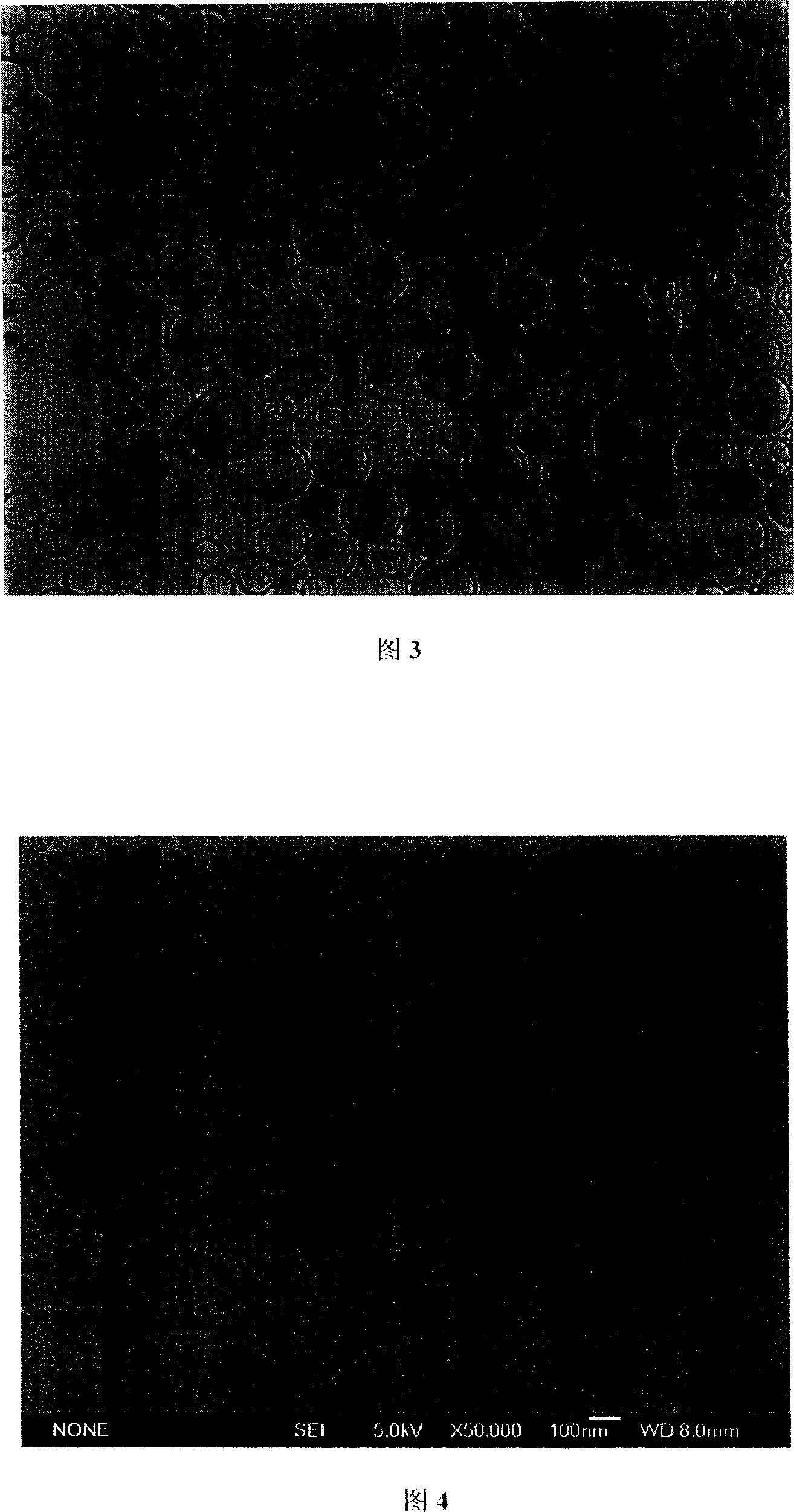

[0038] In a 250ml reactor with a stirring device, add 235ml of xylene mixed with 1.67g of ethyl cellulose and 0.83g of Span 60, heat up to 50°C, and add a 6% glucomannan aqueous solution under stirring 100g, dropwise add 50ml of cross-linking agent epichlorohydrin, dropwise for 2 hours. After the dropwise addition, the temperature was raised to 60° C. for 8 hours, and the microspheres solidified. The microspheres are filtered out, the dispersion medium is recovered, and the microspheres are washed repeatedly with a large amount of water. Light round microspheres with a particle size of 200-300um. The optical microscope photos of the gel microspheres are shown in Figure 2.

Embodiment 3

[0040] Preparation of Konjac Glucomannan Gel Microspheres in Liquid Paraffin System.

[0041]In a 250ml reactor with a stirring device, add 150ml of liquid paraffin mixed with 1.5g of Span 80, raise the temperature to 50°C, add 50g of glucomannan aqueous solution with a concentration of 6% under stirring, and add the crosslinking agent dropwise Add 25ml of epichlorohydrin dropwise for 1 hour. After the dropwise addition is completed, heat up to 60°C for 8 hours. The microspheres solidify, filter out the microspheres, and wash the microspheres repeatedly with a large amount of water to obtain a particle size of 120-200um. between the microspheres.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com