Plastic net film, continuous production, method and apparatus thereof

A technology of production equipment and production method, which is applied in the field of plastic film products, can solve problems such as not being able to meet the use requirements of high-strength plastic film, and achieve the effects of simple production method and equipment structure, high-efficiency continuous production, and expanded application fields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

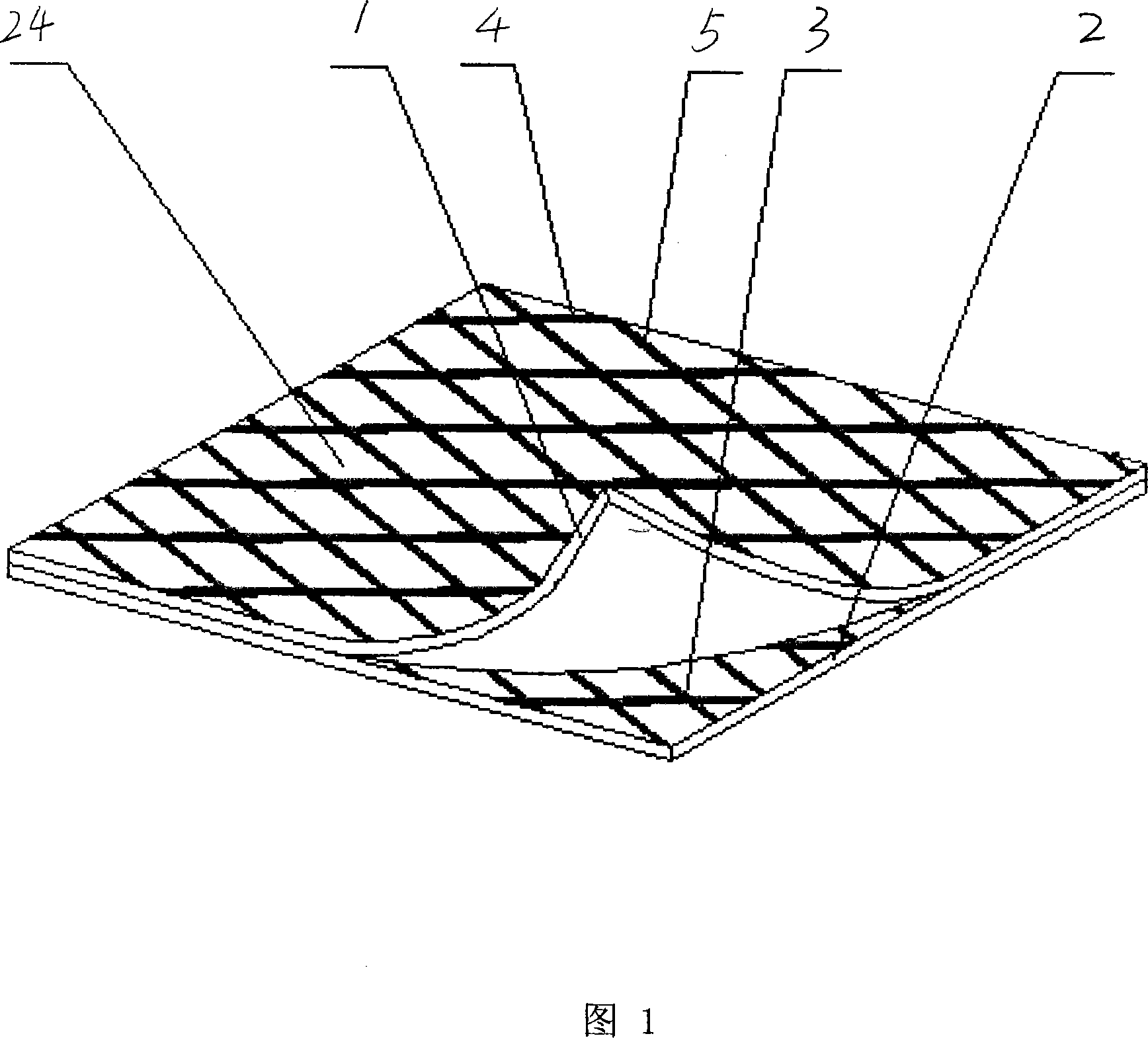

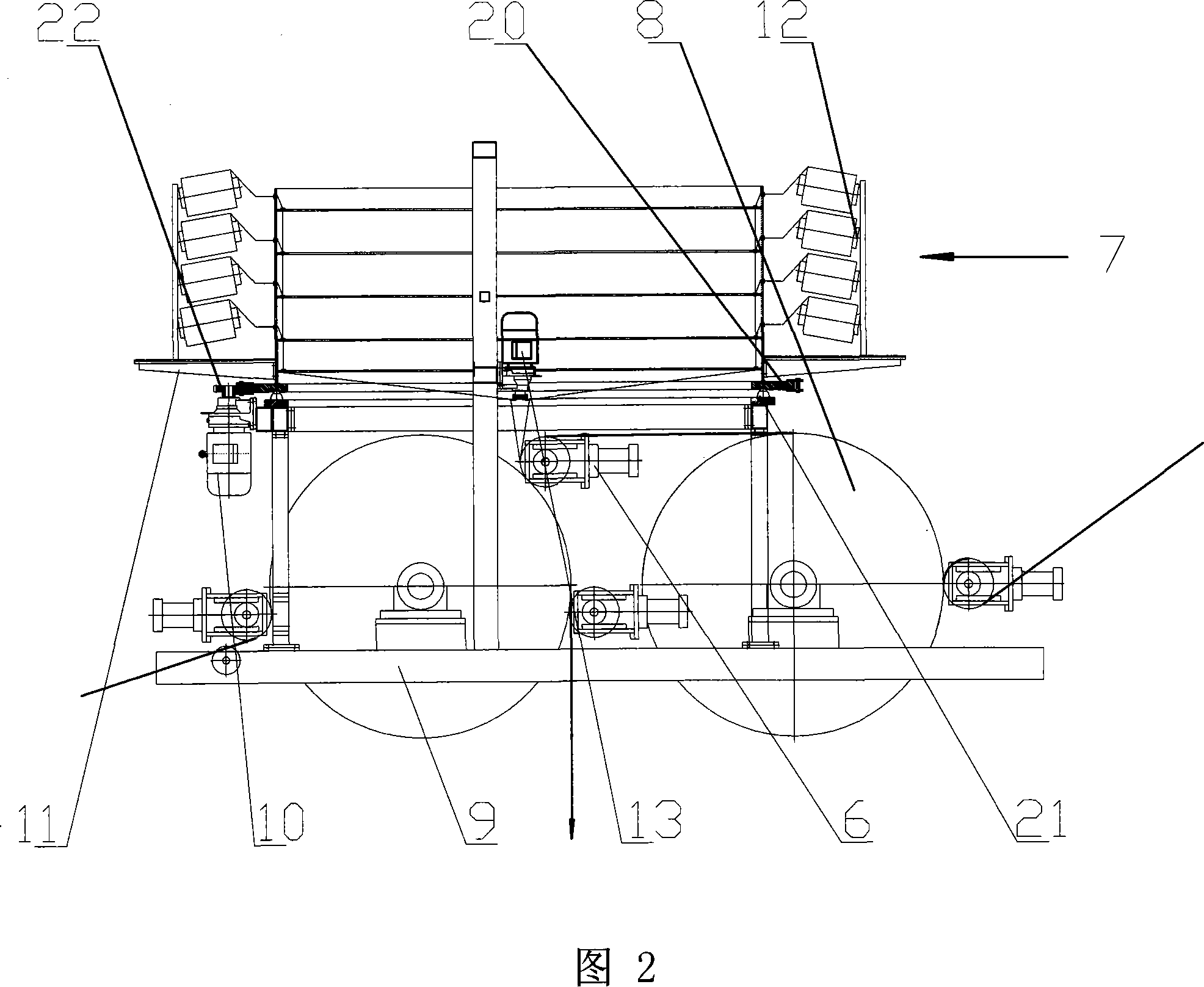

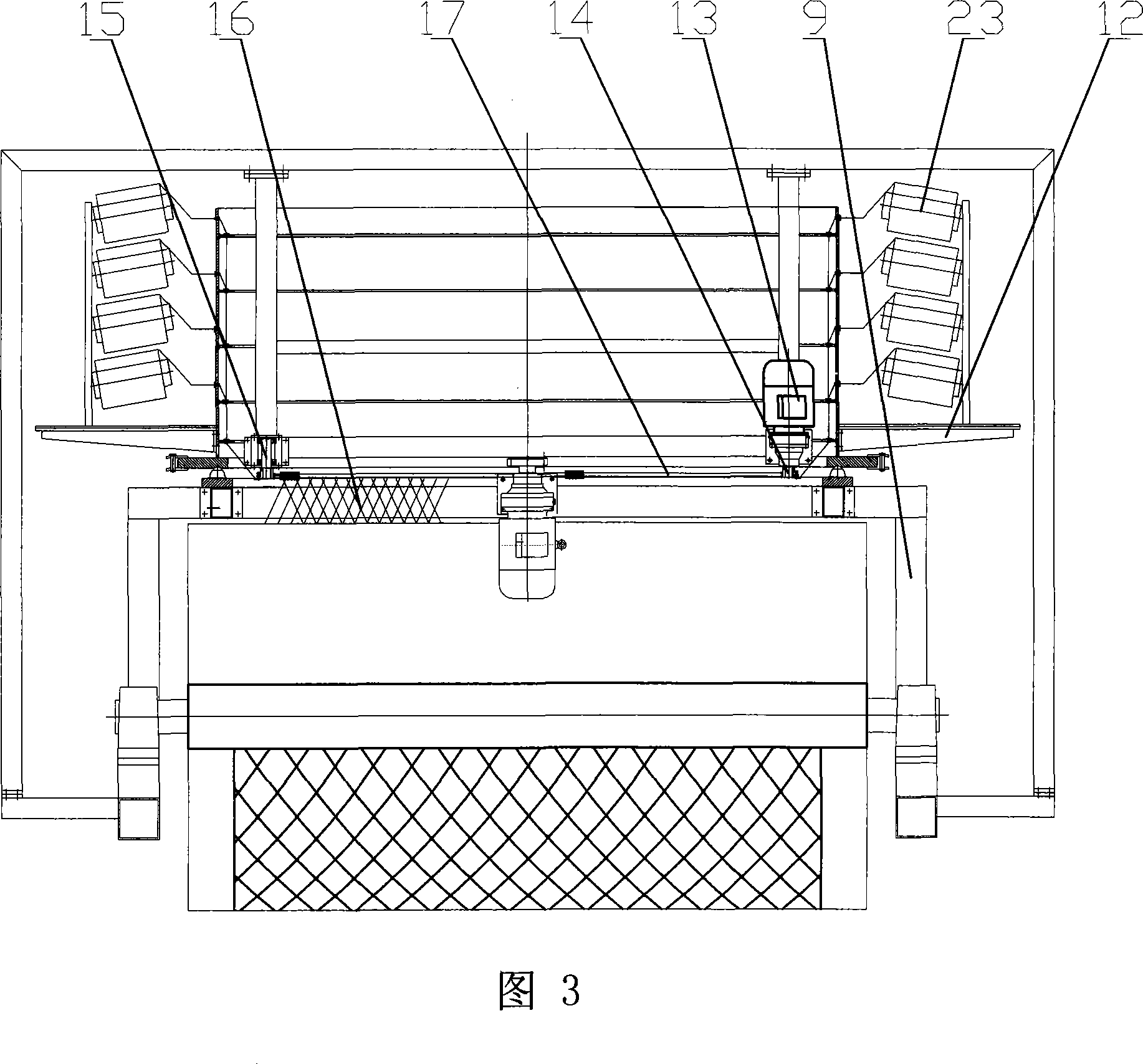

[0022] The structure of the production equipment of the embodiment of the present invention is shown in Figures 2, 3, 4 and 5: there is a web forming device 7 and a plastic compounding device 8, and the plastic compounding device 8 adopts the prior art. The structure of the web forming device 7 is to be provided with a frame 9, on which a rotary creel 11 driven by a driving device (drive device such as a variable frequency motor, a reducer) 10 is arranged, and a plurality of Yarn fixing shaft 12 arranged horizontally and vertically in an orderly manner; on frame 9, also be fixed with drive sprocket 14, driven sprocket 15 driven by driving device (drive devices such as variable frequency motor, reducer) 13, and driving sprocket 14. The driven sprocket 15 is engaged with a chain 16, and the chain 16 is placed in the chain guide rail 17 fixed on the frame 9; a plurality of evenly arranged yarn guide plates 18 are fixed on the chain 16, and the yarn guide plate 18 Yarn guide hole ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com