Hollowed-out flower striped sock diaphanous and breathable shell fabric provided with composite layer

A composite fabric and composite layer technology, applied in the field of textile fabrics and fabrics, can solve the problems of lack of three-dimensional sense, unable to meet the needs of modern people, and lack of light transmission and ventilation, and achieve the effect of enhancing three-dimensional sense.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

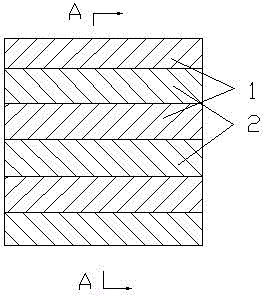

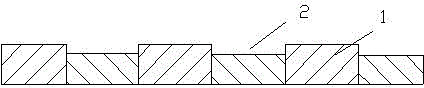

[0011] see figure 1 and figure 2 , The present invention relates to a hollow flower striped sock light-transmitting and air-permeable fabric with a composite layer, comprising a hollow flower part 1 and a colored stripe part 2. Both the hollow flower part 1 and the colored stripe part 2 are bar-shaped and have the same width. The hollow flower part 1 and the colored stripe part 2 are on the same plane, interlaced and connected in parallel. Due to the different shrinkage properties of the materials of the hollow flower part 1 and the color stripe part 2, a concave-convex structure is formed in which the hollow flower part 1 protrudes and the color stripe part 2 is concave.

[0012] The hollow flower part 1 is made of fabric, and the fabric adopts a composite fabric, and the composite fabric is composed of a bottom layer, a middle layer and a surface layer, and the bottom layer and the surface are connected as a whole by the middle layer, wherein the surface layer is mesh clo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com