Secured fixing screw

A technology of anti-loosening and screw shank, which is applied in the direction of bolts, nuts, threaded fasteners, etc., and can solve problems such as high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

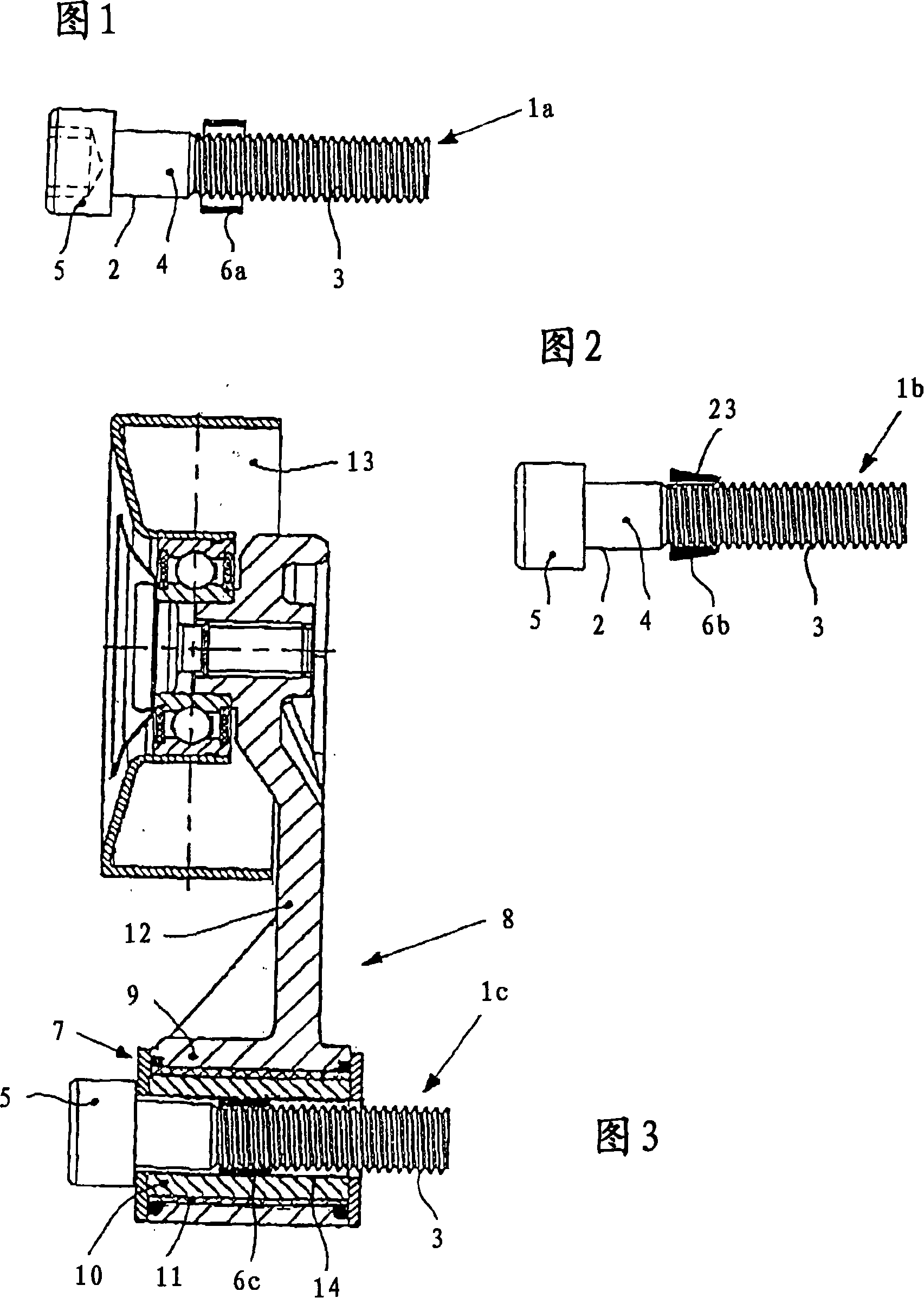

[0017] FIG. 1 shows a hexagon socket head cap screw, which can be used as a connecting screw 1a for a structural part of a traction tool drive. A screw shank 2 has a threaded section 3 and a further smooth-surfaced section 4 which extends between the screw head 5 and the threaded section 3 . The threaded section 3 is provided with a cylindrical sleeve 6a, which serves to secure the connecting screw 1a, on this threaded section, for example, a sleeve is inserted into the receiving hole for the connecting screw 1a and thus locally narrows the receiving diameter. Due to the narrowed diameter and the elastic sleeve 6a, the connecting screw 1a is fastened in the receiving opening in a loose-fixed manner.

[0018] FIG. 2 shows the connection screw 1b in combination with a sleeve 6b shrink-fitted using thermal technology. This type of fixing ensures that the sleeve 6b is immovably fixed on the threaded section 3 of the connecting screw 1b. In order to allow the connecting screw 1b ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com