Blanking turn-over device of vehicle cladding element punching product line and method thereof

A technology of automobile cover parts and turning devices, which is applied in the direction of feeding devices, positioning devices, storage devices, etc., which can solve the problems of low equipment utilization rate, high use cost, and large equipment dimensions, and achieve small footprint and low manufacturing cost. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

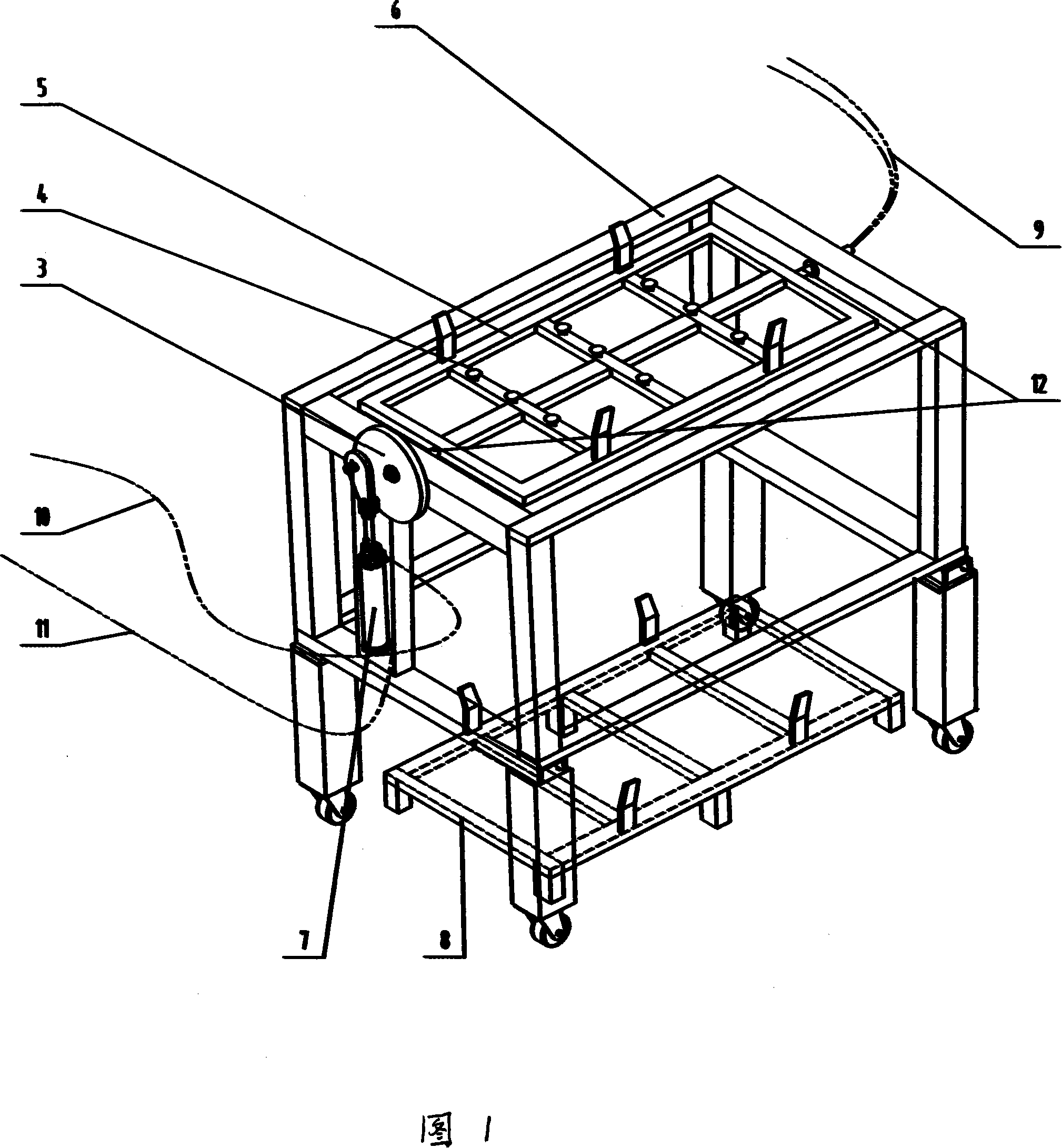

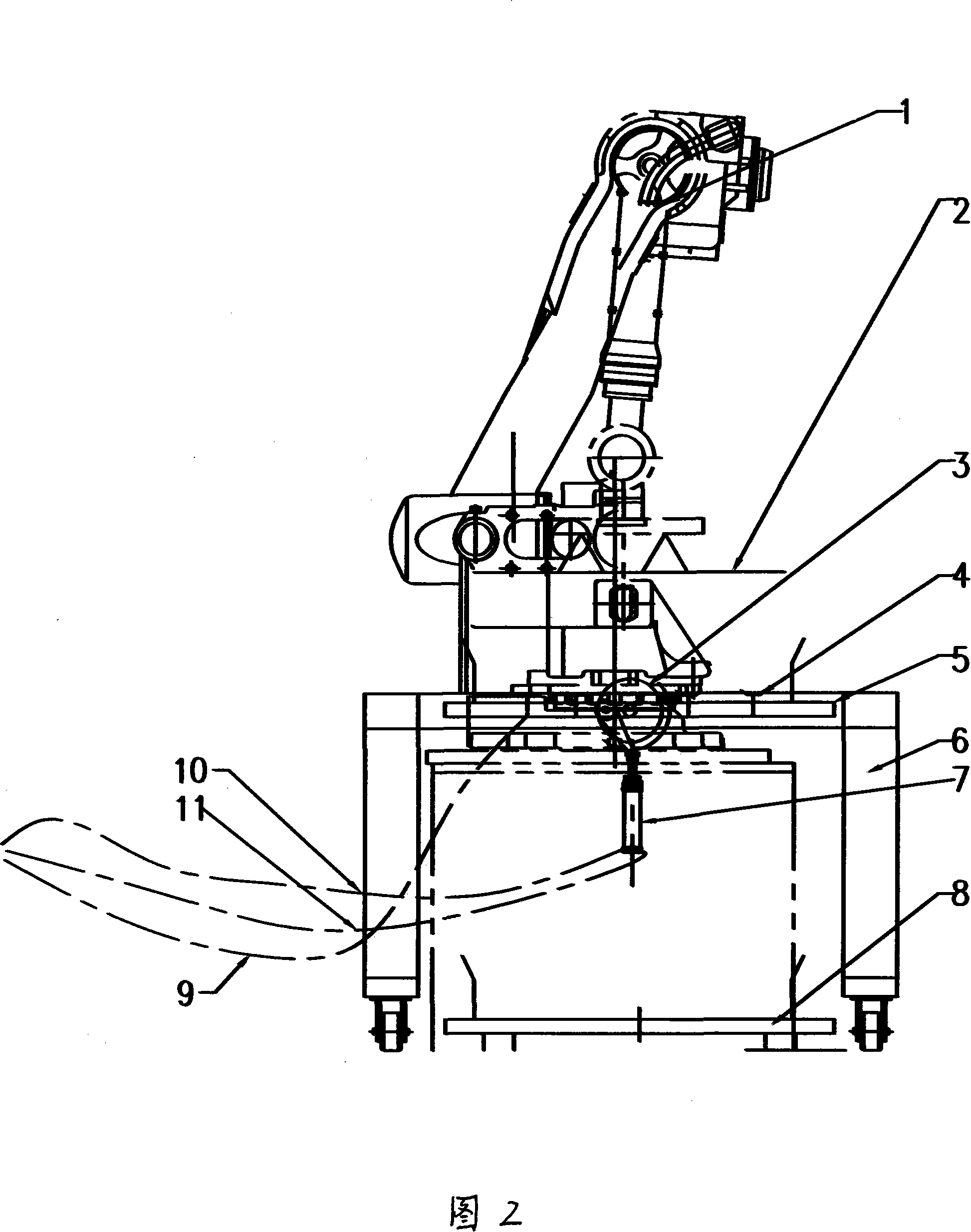

[0018] Referring to Figure 1 and Figure 2, a blanking and overturning device for the stamping production line of automobile panels, including: a main body 6 of the overturning device; The turning mechanism 3 is connected with the turning device main body 6 and the turning bracket 5 through the turning shaft 12, and is slidably connected with the turning cylinder 7; the plate sucker 4 is fixed on the turning bracket 5; the automatic air source pipelines 9, 10, 11, one end of which is connected to the automatic air source of the automatic stamping production line of the automobile cover part, the other end of the pipeline 9 passes through the turning shaft 12 to provide air for the sheet sucker 4, the other end of the pipeline 10, the other end of the pipeline 11 and the air intake of the turning cylinder 7 (outlet) mouth connection.

[0019] The blanking and turning device of the automobile panel stamping production line of the present invention is electrically connected with t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap