Mining environment reconstructed continuous mining afterwards filling mining method

A filling mining method and environmental technology, applied in surface mining, underground mining, special mining, etc., can solve the problems of high dry ton cutting ratio, inability to realize safe, efficient, continuous and low-cost mining, and difficulty in mastering small and medium-sized mines. The recovery rate and productivity increase, the mining environment is safe and reliable, and the effect of reducing the ore dilution rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

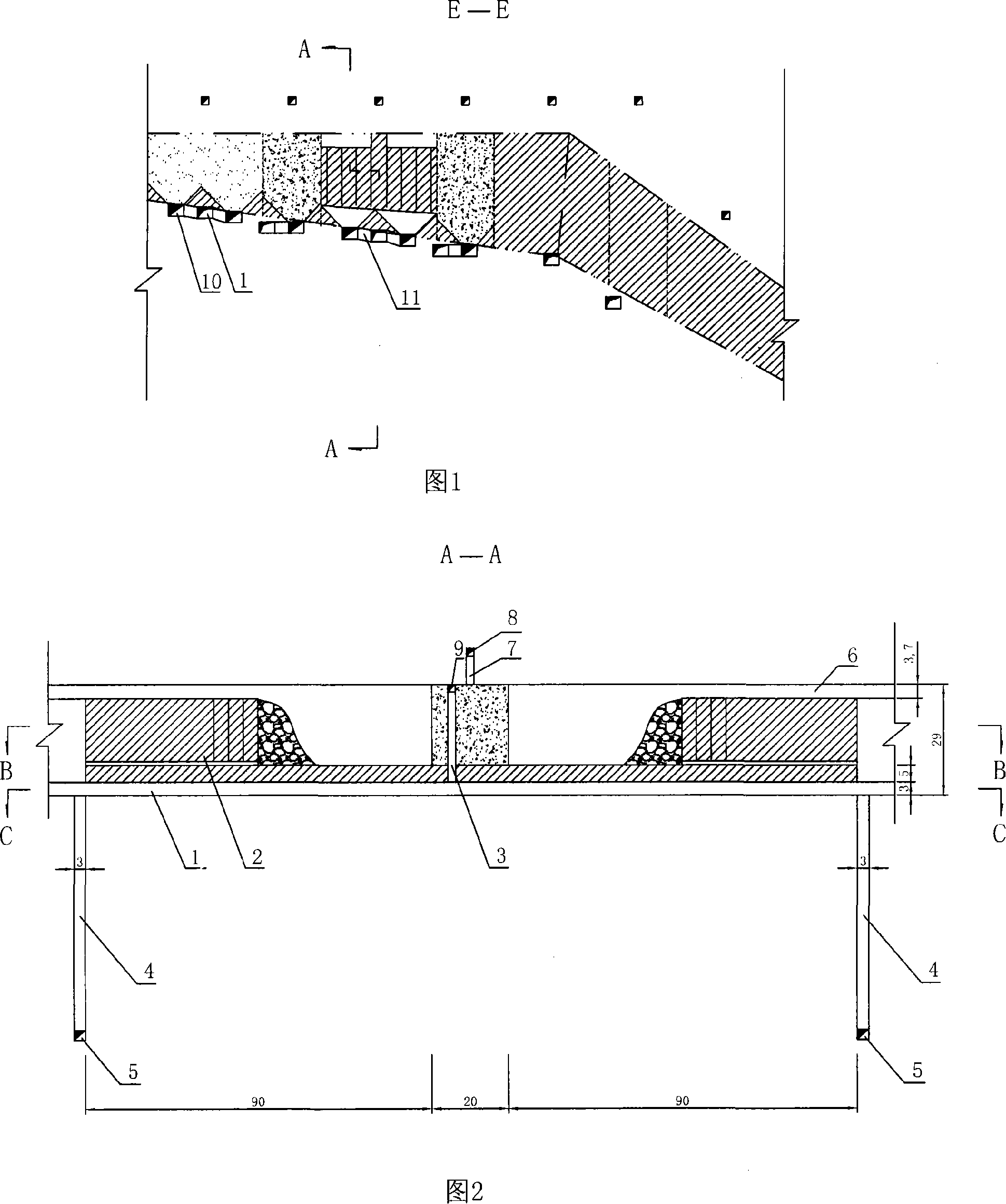

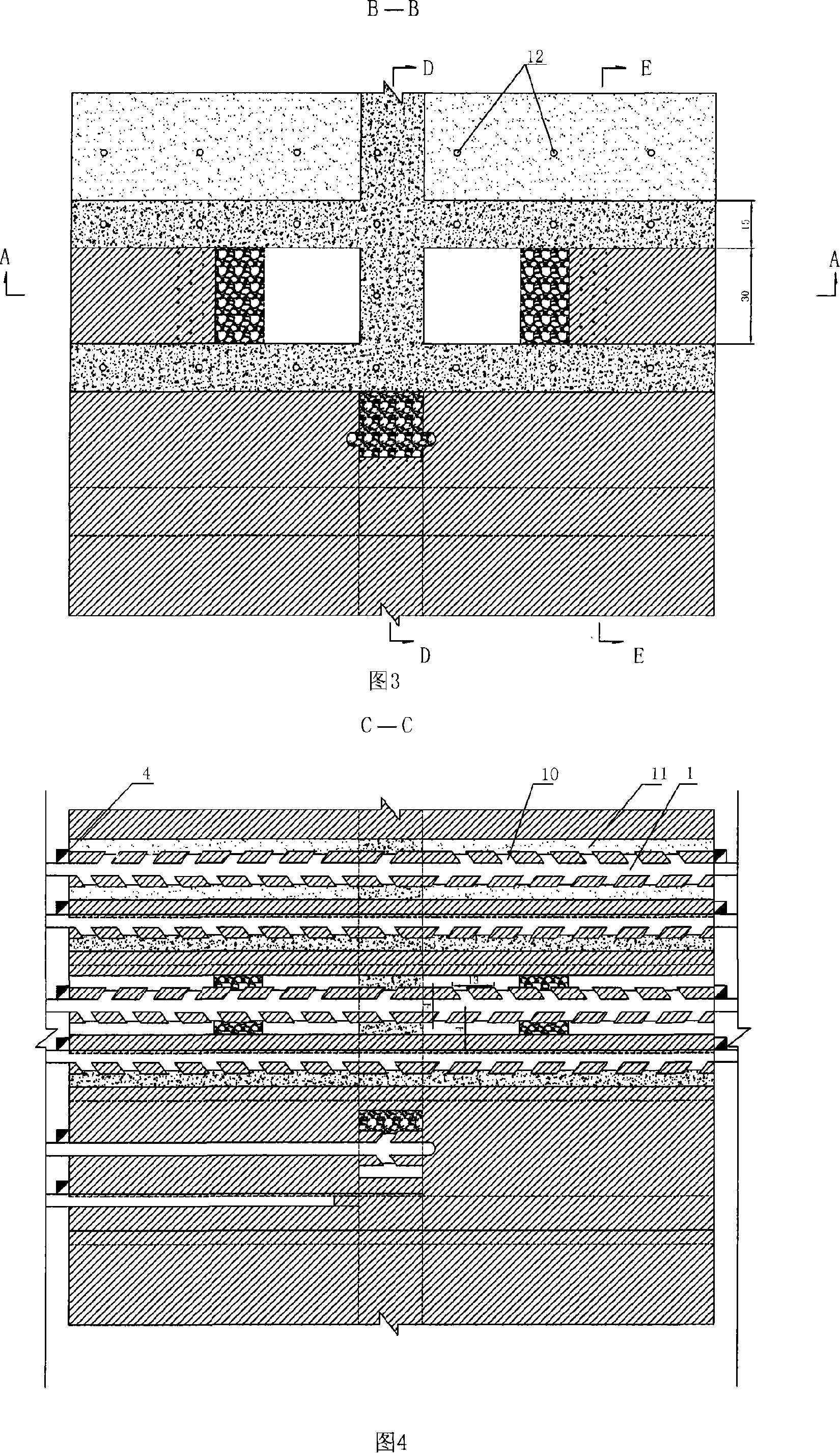

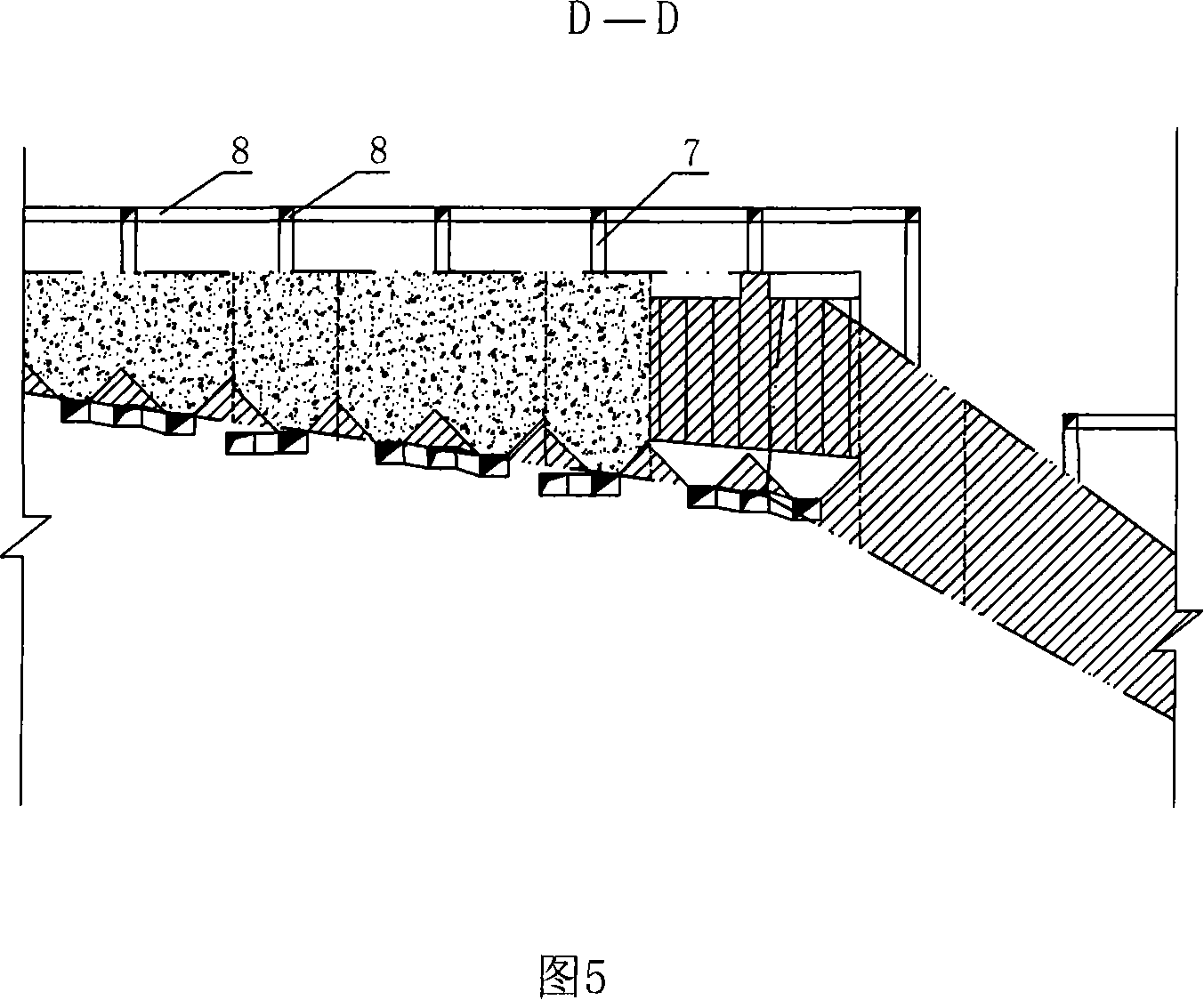

[0022] The specific use case of the mining method proposed by the present invention is: along the ore body inclination direction, mining a strip-shaped ore section in the middle of the ore body, with a width of 20 meters, and mining a 15-meter-wide ore section at an interval of 30 meters perpendicular to the ore section; Firstly, a rock-drilling roadway is excavated in the upper part of the mine section, and perpendicular to this direction, a rock-drilling roadway is excavated at an appropriate distance on both sides of the ore body and communicated in the middle to form a ventilation circuit, and a rock-drilling cavern is formed by expanding the side of the rock-drilling roadway. Excavate the mine exit roadway at the bottom of the ore body, cut and pull the bottom from the middle to both sides to construct the bottom structure of the trench. The 30m wide ore block adopts double trench trenches for ore exit, and the mine exit roadway is arranged in the center of the two trenches...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com