Logging-while-drilling orientation measurement error compensation method based on micro-quartz angular rate sensor

An angular rate sensor and measurement error technology, applied in the field of detection, can solve the problems of large measurement error, large zero drift, affecting the accuracy of azimuth angle measurement while drilling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solution of the present invention will be described in detail below with reference to the drawings and specific embodiments.

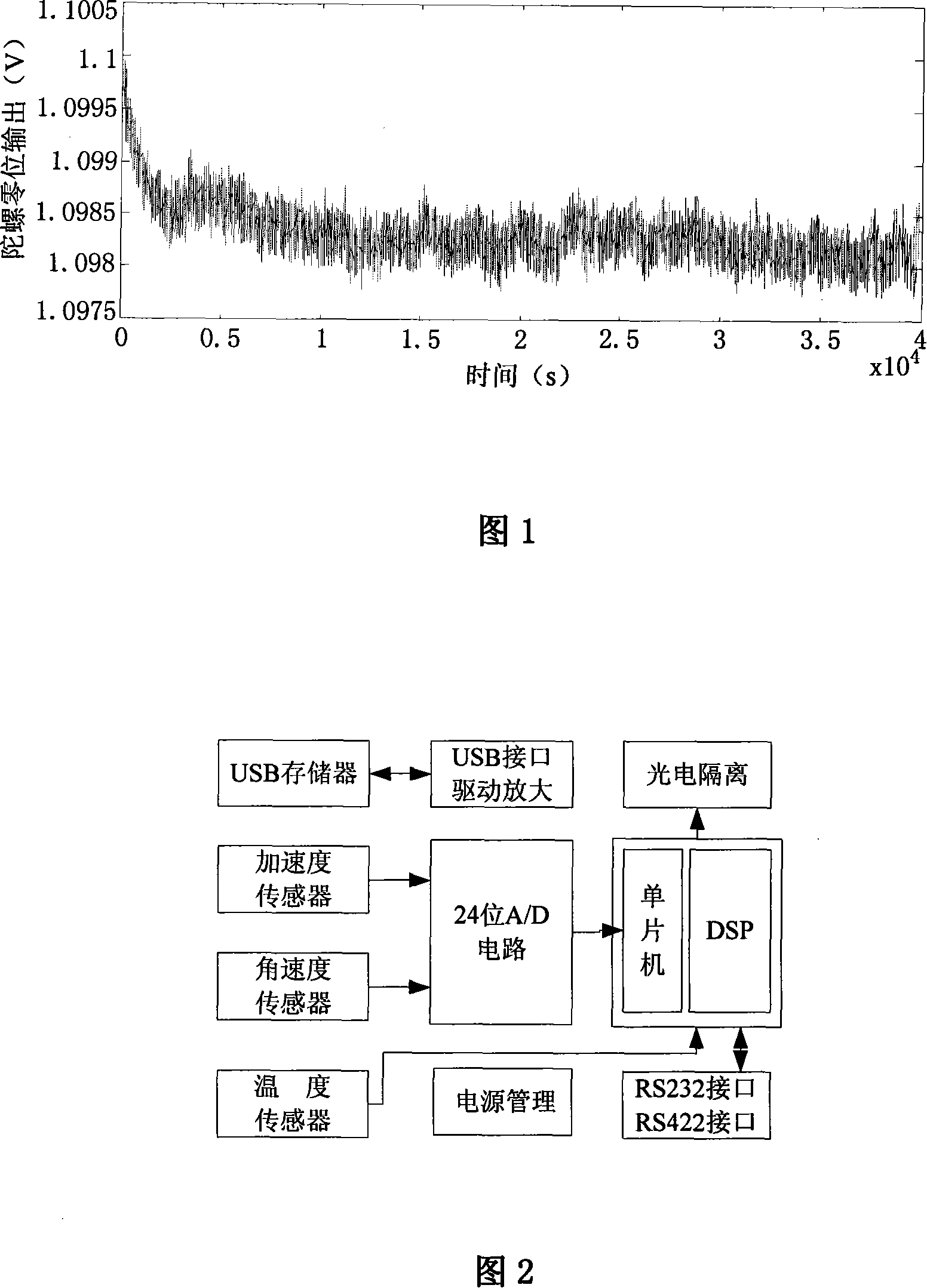

[0016] Figure 1 shows the zero output curve of the micro-quartz angular rate sensor. It can be seen from Figure 1 that the zero drift and scale factor change of the angular rate sensor is a complex nonlinear change process, which is difficult to describe with an accurate model . It is not only related to the running time of the system, but also related to the ambient temperature of the system running, and these two parameters have an effect on the zero output signal and scale factor of the angular rate sensor at the same time. At different system working time points, even if the system operating temperature is the same, there is a large deviation in the angular rate sensor zero output and scale factor results; similarly, when the angular rate sensor is started at different system operating temperatures, the angular rate sensor zero...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com