Continuous gradient counterflow extraction producing soybean concentrate protein method and equipment

A technology for soybean protein concentration and extraction, which is applied in the fields of protein food ingredients, protein composition of vegetable seeds, food science, etc., can solve the problems of emission, high energy consumption, poor color and flavor, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0115] 1. The low-temperature defatted soybean meal with a feeding rate of 800kg / h is transported to the raw material storage tank with a bucket elevator. There is a rotary metering and feeding device at the outlet of the lower cone of the storage tank, and the feeding is constant through frequency conversion;

[0116] 2. The material is continuously transported to the prepreg device by the scraper machine, and the material is mixed with the extract obtained in the extraction step, with a volume of 2.5m 3 , the material-solvent ratio of the pre-soaking step is 1:3, the temperature is 50°C, and the pre-soaking time is 15 minutes;

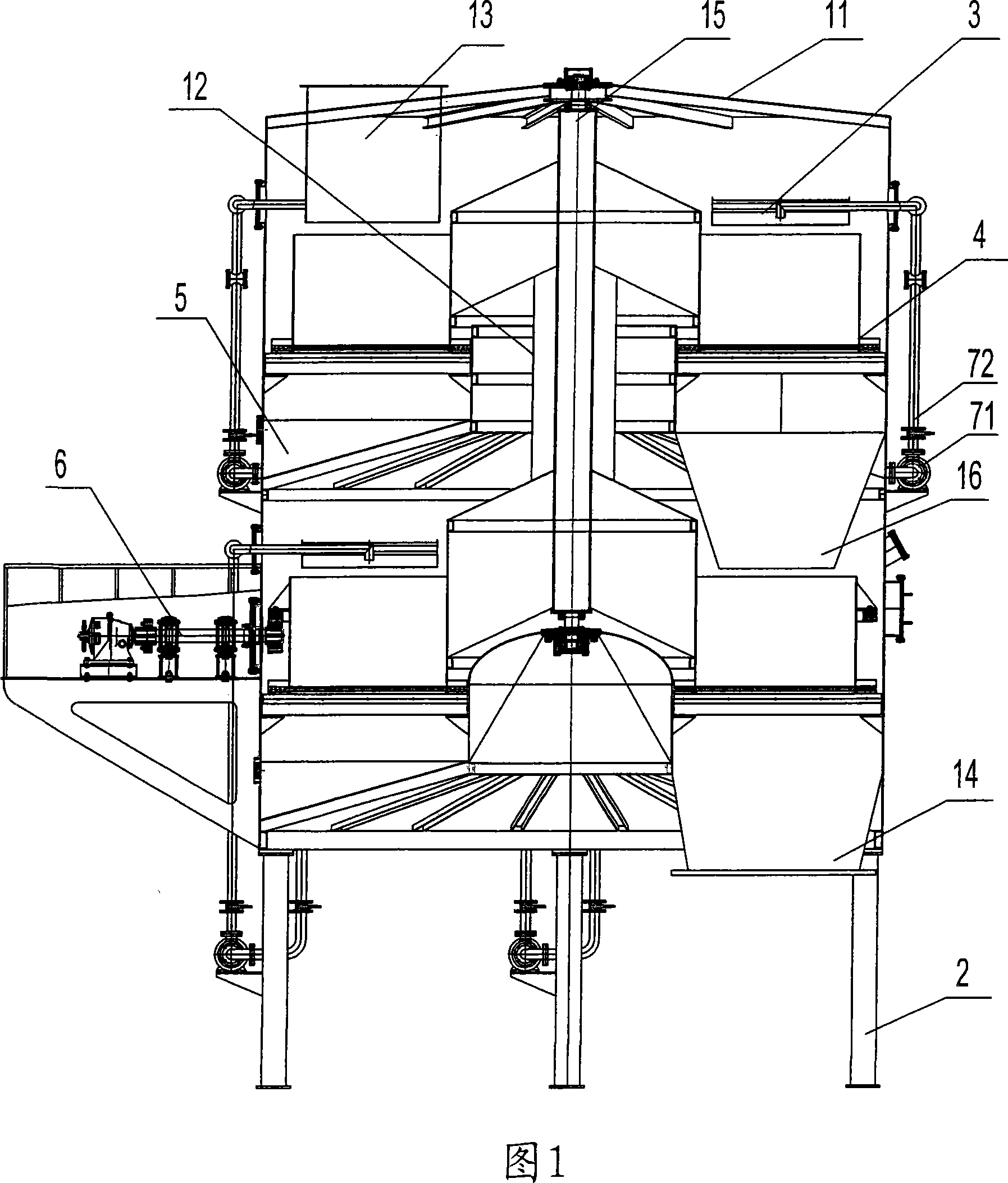

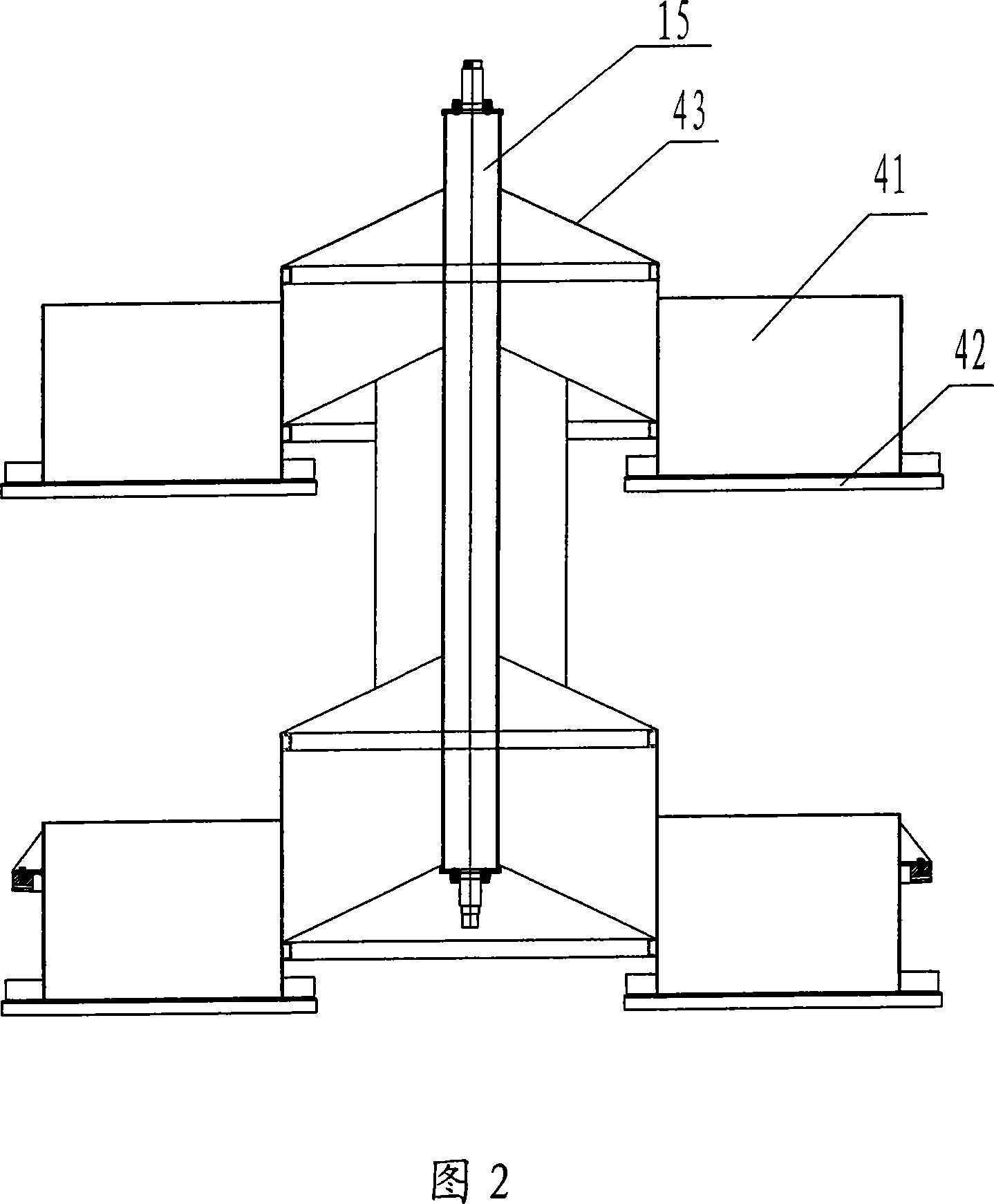

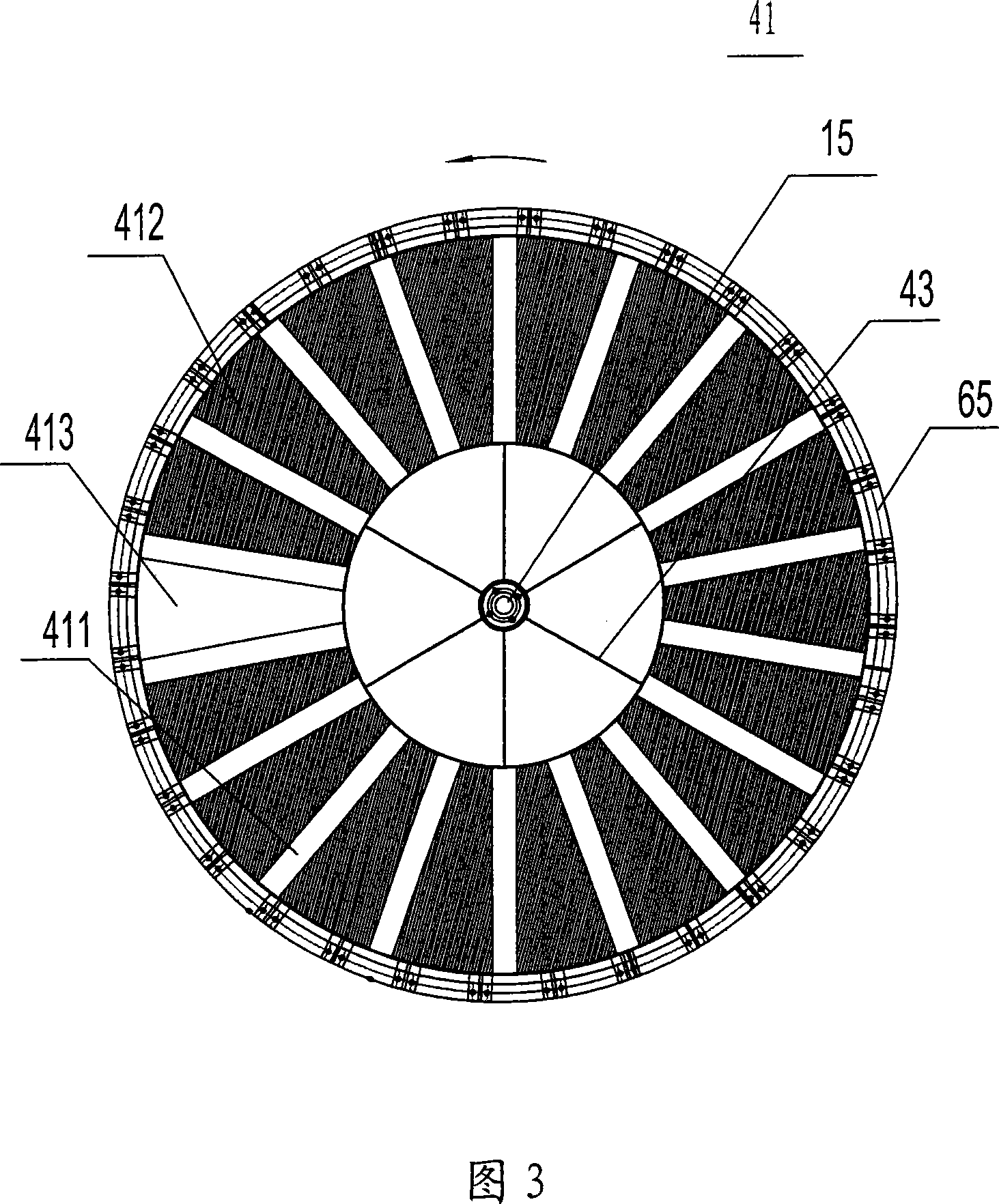

[0117] 3. The wet material corrected by the above-mentioned prepreg is transferred to the above-mentioned double-layer compound continuous extraction device of the present invention together with the extraction solvent, the extraction temperature is 50° C.; the material-solution ratio is 1: 3, and the concentration of the extraction solvent is 65% (vo...

Embodiment 2

[0124] 1. The low-temperature defatted soybean meal is transported to the raw material storage tank by a bucket elevator. There is a rotating metering and feeding device at the outlet of the lower cone of the storage tank. The feeding volume is adjusted to 800kg / h through frequency conversion speed regulation;

[0125] 2. The scraper machine transports the material to the prepreg device, where the material is mixed with the extraction solution at a temperature of 40°C and the prepreg time is 10 minutes, and then directly enters the continuous gradient countercurrent compound extraction device;

[0126] 3. Extract in a continuous gradient countercurrent compound extraction device, the operation method is the same as in Example 1, and the specific extraction conditions are: the extraction time is 210 minutes; the extraction temperature is 40 ° C; the material-solvent ratio is 1: 4, and the solvent concentration is 70%. (volume fraction), the material moisture content after extrac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com