Material for use in the manufacturing of luminous display devices

A device, oxide technology, applied in organic light-emitting diodes, materials used in organic light-emitting diodes, preparing the field of materials, can solve the problems of chemical stability and low conductivity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

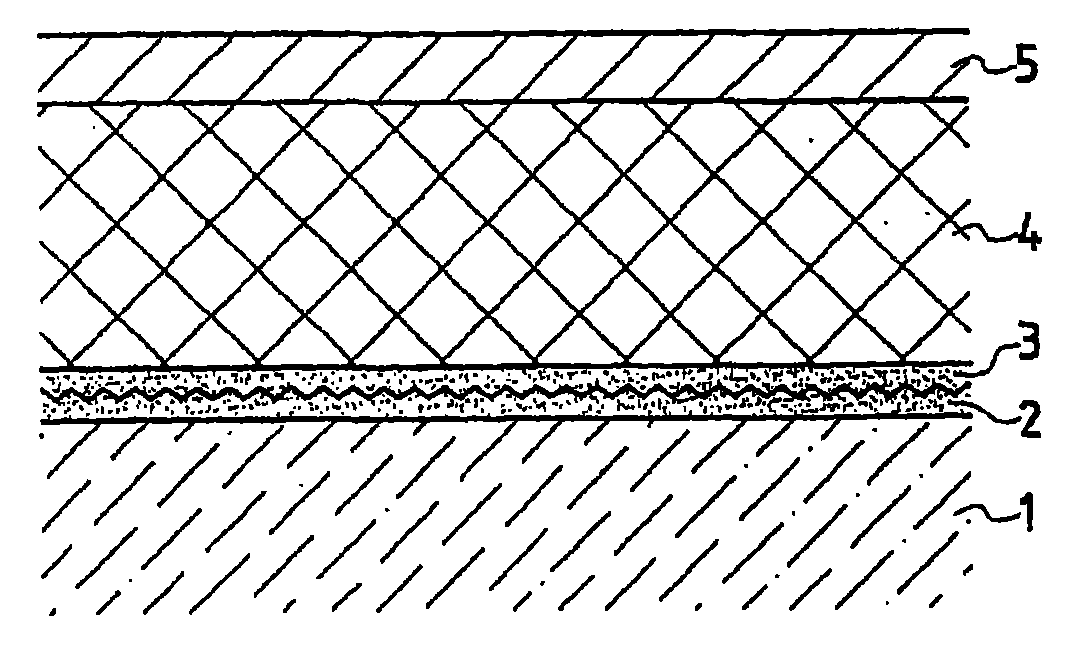

[0140] Example 1: Glass support coated with ITO layer and ATO layer

[0141] 1. A product sold by Samsung Corning Co., which uses a vacuum spraying technique to coat an ITO layer on a glass substrate of 0.7 mm was used.

[0142] This ITO layer has the following properties:

[0143] · Thickness is 192nm,

[0144] · The surface impedance is 7.6Ω / □,

[0145] · Average roughness (Rrms) measurement 5μm 2 4.7nm,

[0146] · Peak-valley roughness (Rpv) measurement 5μm 2 31.1nm,

[0147] · Working performance between 4.3-4.6eV,

[0148] · Transmittance is 83% within the visible range.

[0149] 2. The coating solution is prepared by adding tin dichlorodiacetate SnCl 2 (OAc) 2 Dissolve in ethanol with the addition of 4-hydroxy-4-methyl-pentanone (CAS 123-42-2) as a stabilizer. The relative amounts of tin and antimony were calculated to be 7 mol% for the final doping. The concentration of the stabilizer relative to tin was 2 mol%. Ethanol was added to give a final tin concentr...

Embodiment 2

[0159] Embodiment 2 (comparison)

[0160] For comparison purposes, a layer of ATO was directly deposited on a glass substrate with the same precursor solution used in Example 1 under the same deposition and heat treatment conditions, but no coated ITO layer was present on the glass substrate.

[0161] The properties of the resulting coating are:

[0162] · Surface impedance: 1890Ω / □,

[0163] · Optical transmittance: 85%,

[0164] · Working performance: 4.8 to 5.2eV,

[0165] Coating thickness: 108nm,

[0166] · Average roughness (Rrms): at 100nm 2 Measured within a square area to be 1nm,

[0167] · Peak-valley roughness (Rpv): at 100nm 2 Measured within the square area to be 3.6nm,

Embodiment 3

[0168] Embodiment 3 (comparison)

[0169] For comparison purposes, eight consecutive ATO layers were deposited directly on the substrate with the same precursor solution as used in Example 2 under the same deposition and thermal post-treatment conditions.

[0170] The properties of these coatings are:

[0171] · Surface impedance: 50 to 55Ω / □,

[0172] · Optical transmittance: 65%,

[0173]· Working performance: 4.8 to 5.2eV,

[0174] Coating thickness: 600nm,

[0175] · Average roughness (Rrms) measurement 100nm 2 The square area is 2.5nm,

[0176] · Peak-valley roughness (Rpv) measurement 100nm 2 The square area is 8nm,

[0177] The properties of supports coated only with an ITO layer, the coated supports according to inventive example 1 (ATO / ITO) and the coated supports according to comparative examples 2 and 3 are listed in the table below:

[0178] ITO

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com