Active array base board for plane display and its repair method

A flat-panel display and active array technology, which is applied in the manufacture of electric solid-state devices, semiconductor devices, and semiconductor/solid-state devices, etc., can solve the problems of increased load, abnormal picture, slow response speed, etc., and achieve the effect of reducing resistance and reducing load.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

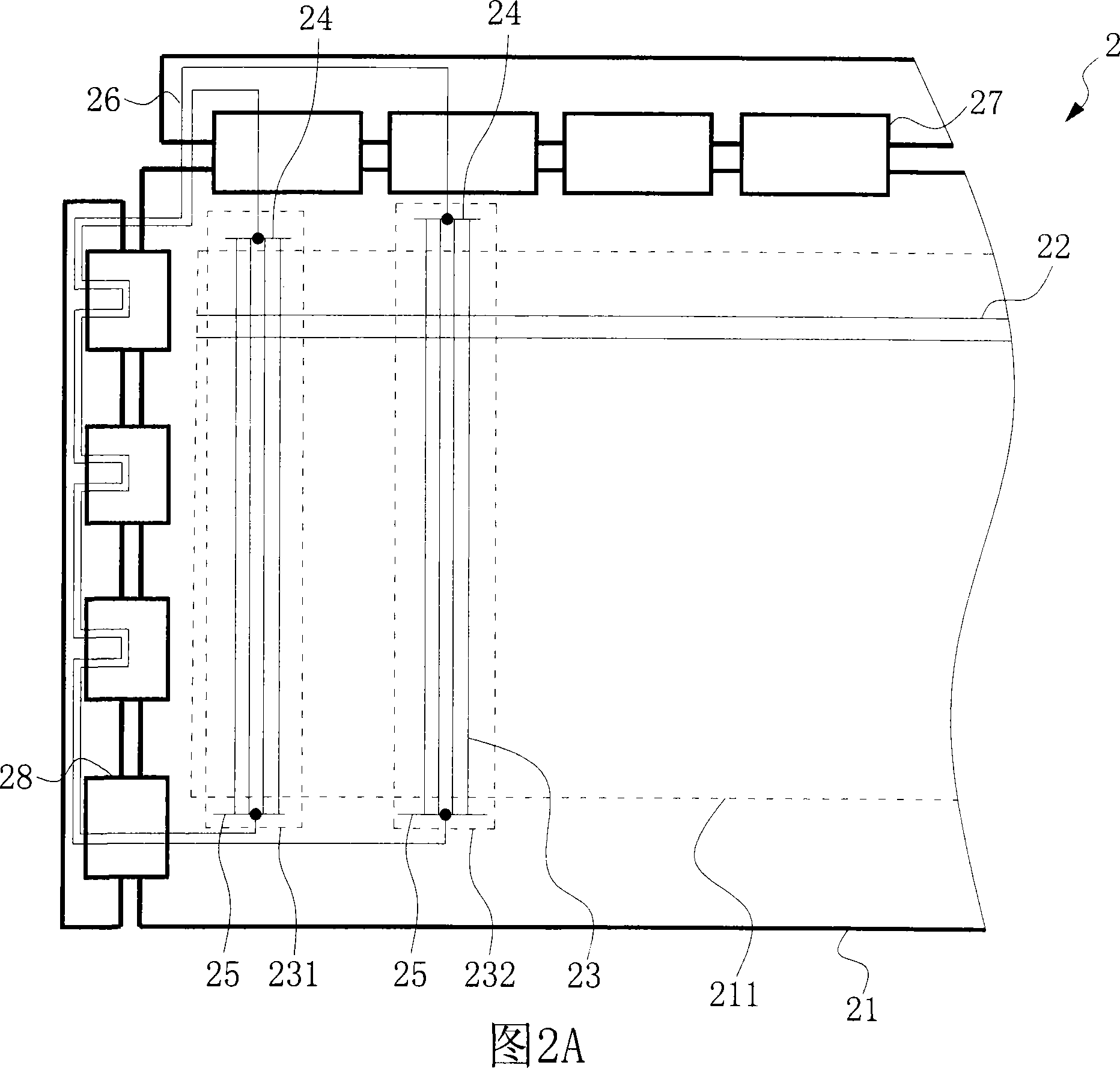

[0083] FIG. 2A is a schematic diagram of an active array substrate for a flat panel display according to a first preferred embodiment of the present invention. The active array substrate 2 for a flat panel display according to the first preferred embodiment of the present invention includes: a substrate 21, a plurality of scanning lines 22, a plurality of data lines 23, a plurality of first repair lines 24, a plurality of second repair lines 25 and A plurality of third repair lines 26. The substrate 21 has a display area 211 , and a plurality of scan lines 22 and a plurality of data lines 23 are arranged on the substrate 21 and cross each other in the display area 211 but are not electrically connected. On the other hand, a plurality of first repairing lines 24 and a plurality of second repairing lines 25 are arranged on the substrate 21, respectively intersecting with the plurality of data lines 23 on the upper side and the lower side of the display area 211, but in general, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com