Acoustic surface wave microhydrogen sensor and its production process

A surface acoustic wave and manufacturing process technology, used in the analysis of solids using sonic/ultrasonic/infrasonic waves, material analysis using sonic/ultrasonic/infrasonic waves, instruments, etc., can solve the problem of low sensitivity of hydrogen sensors, and achieve absolute concentration measurement. , enhance the sensitivity, reduce the effect of the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

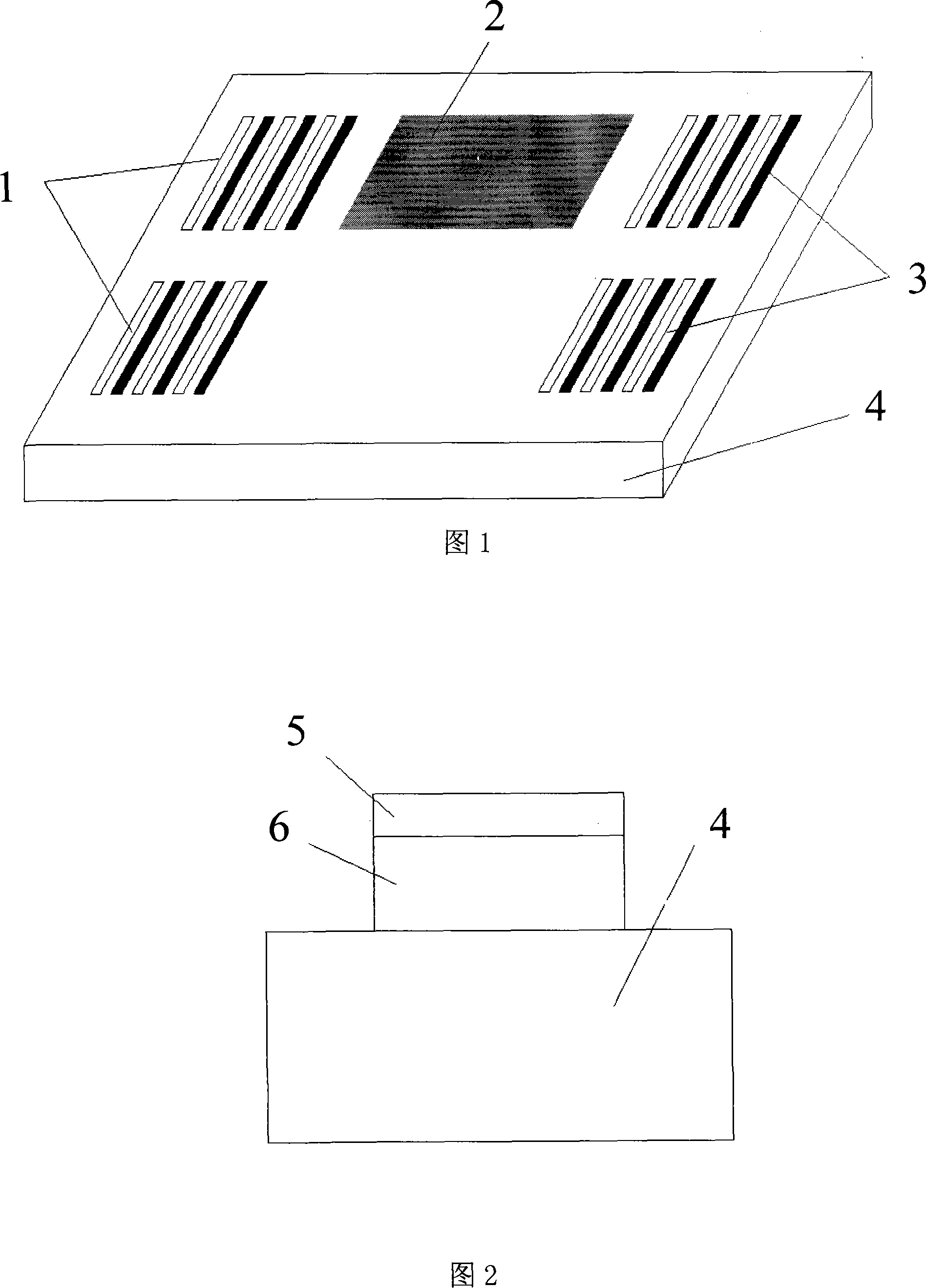

[0026] As shown in Figure 1 and Figure 2, the surface acoustic wave micro-hydrogen sensor of the present invention mainly includes: piezoelectric substrate, input interdigital transducer, output interdigital transducer and hydrogen sensitive film, input interdigital transducer and The aluminum interdigital electrode in the output interdigital transducer is attached to the piezoelectric substrate (PZT4), and the hydrogen-sensitive film is composed of a palladium-silver alloy film and a tin dioxide film. The tin dioxide film is attached to the piezoelectric substrate, and the palladium The silver alloy film is attached to the tin dioxide film to form a double-layer sensitive film. The tin dioxide nano film is 50nm thick, the length and width are 200 and 128μm respectively, the palladium-silver alloy film is 20nm thick, and the palladium / silver mass ratio is 75 / 25, the length and width of the interdigital electrodes in the interdigital transducer are 12 and 128 μm, respectively, ...

Embodiment 2

[0038] As shown in Figure 1 and Figure 2, the surface acoustic wave micro-hydrogen sensor of the present invention mainly includes: piezoelectric substrate, input interdigital transducer, output interdigital transducer and hydrogen sensitive film, input interdigital transducer and The aluminum interdigital electrode in the output interdigital transducer is attached to the piezoelectric substrate (PZT4), and the hydrogen-sensitive film is composed of a palladium-silver alloy film and a tin dioxide film. The tin dioxide film is attached to the piezoelectric substrate, and the palladium The silver alloy film is attached to the tin dioxide film to form a double-layer sensitive film. The tin dioxide nano film is 100nm thick, the length and width are 200 and 128μm respectively, the palladium-silver alloy film is 20nm thick, and the palladium / silver mass ratio is 75 / 25, the length and width of the interdigital electrodes in the interdigital transducer are 12 and 128 μm, respectively,...

Embodiment 3

[0050] As shown in Figure 1 and Figure 2, the surface acoustic wave micro-hydrogen sensor of the present invention mainly includes: piezoelectric substrate, input interdigital transducer, output interdigital transducer and hydrogen sensitive film, input interdigital transducer and The aluminum interdigital electrode in the output interdigital transducer is attached to the piezoelectric substrate (PZT4), and the hydrogen-sensitive film is composed of a palladium-silver alloy film and a tin dioxide film. The tin dioxide film is attached to the piezoelectric substrate, and the palladium The silver alloy film is attached to the tin dioxide film to form a double-layer sensitive film. The tin dioxide nano film is 50nm thick, the length and width are 200 and 128μm respectively, the palladium-silver alloy film is 40nm thick, and the palladium / silver mass ratio is 75 / 25, the length and width of the interdigital electrodes in the interdigital transducer are 12 and 128 μm, respectively, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com