Glue used for floor veneer film immersion and construction method thereof

A veneer and glue technology, applied in the direction of adhesives, adhesive types, aldehyde/ketone condensation polymer adhesives, etc., can solve problems such as affecting the appearance, achieve the effect of color coordination and improve the appearance of the surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] In this embodiment, the impregnated phenolic glue used has a solid content of 44-48%, a pH of 9-10, and a viscosity of 23-30cp / 30°C (centipoise). Titanium dioxide contains more than 93% titanium. Iron oxide yellow is a 220 mesh powder with a purity of 98%. Oleic acid is refined industrial oleic acid, acid value: 190-220mgKOH / g saponification value: 190-220mgKOH / g. The dispersant is a common dispersant, preferably sodium methylene dinaphthalene sulfonate. The toughening agent is polyvinyl acetate emulsion.

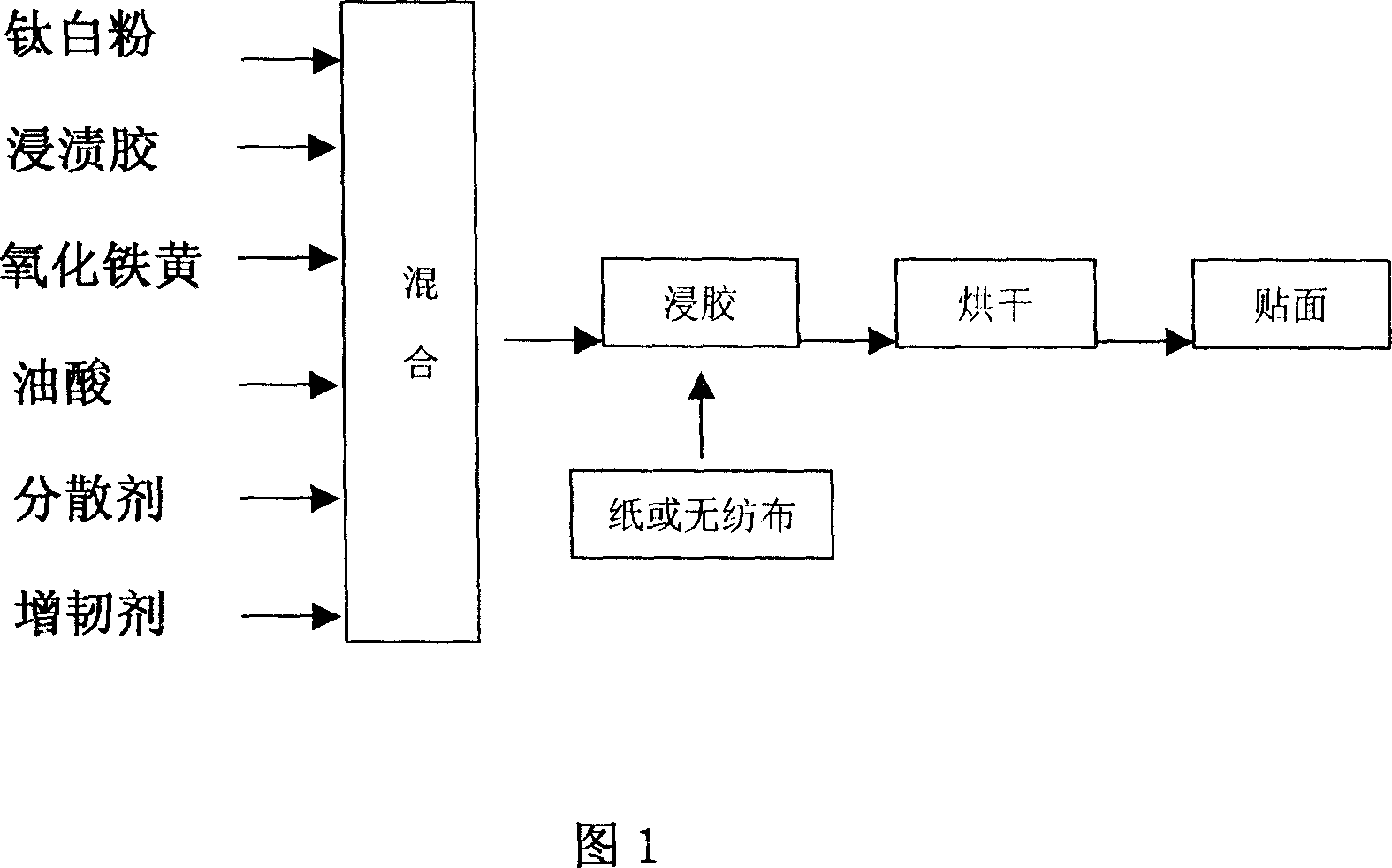

[0014] As shown in Figure 1, impregnate 100 parts of phenolic glue, 20 parts of titanium dioxide, 1.2 parts of oleic acid, 1.5 parts of iron oxide yellow, 0.2 parts of dispersant, and 0.3 parts of toughening agent. Stir and mix the above materials for 25 minutes to obtain a light yellow liquid Viscous glue, then impregnated in the above glue with non-woven fabric, squeezed by double rubber rollers, dried to remove 35% of the water to a semi-dry state, and pasted o...

Embodiment 2

[0016] In this embodiment, the impregnated phenolic glue used has a solid content of 44-48%, a pH of 9-10, and a viscosity of 23-30cp / 30°C (centipoise). Titanium dioxide contains more than 93% titanium. Iron oxide yellow is a 320 mesh powder with a purity of 98%. Oleic acid is refined industrial oleic acid, acid value: 190-220mgKOH / g saponification value: 190-220mgKOH / g. The dispersant is a common dispersant, preferably sodium methylene dinaphthalene sulfonate. The toughening agent is polyvinyl acetate emulsion.

[0017] As shown in Figure 1, impregnate 100 parts of phenolic glue, 15 parts of titanium dioxide, 1.4 parts of oleic acid, 1.5 parts of iron oxide yellow, 0.3 parts of dispersant, and 0.3 parts of toughening agent. Stir and mix the above materials for 30 minutes to obtain a light yellow liquid Viscous glue, then impregnated in the above glue with non-woven fabric, squeezed by double rubber rollers, dried to remove more than 35% of the water, and then it was semi-d...

Embodiment 3

[0019] In this embodiment, the dispersant used is a common dispersant, preferably sodium methylene dinaphthalenesulfonate. The toughening agent is polyvinyl acetate emulsion.

[0020] As shown in Figure 1, impregnate 80 parts of phenolic glue, 20 parts of titanium dioxide, 1.0 part of oleic acid, 1 part of iron oxide yellow, 0.1 part of dispersant, and 0.2 part of toughening agent. Stir and mix the above materials for 20 minutes to obtain a light yellow liquid Viscous glue, then impregnated in the above glue with non-woven fabric, squeezed by double rubber rollers, dried to remove 35% of the water, and then it was semi-dry, and pasted on the wooden floor of the container to get the same light yellow surface effect as wood .

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com