Aluminum nitride/borosilicate glass low-temperature co-fired ceramic substrate material and preparation method thereof

A technology of low-temperature co-fired ceramics and borosilicate glass, which is applied in the direction of circuit substrate materials, printed circuit components, etc., can solve the problems of high cost and achieve the effects of low price, cost reduction and loss reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

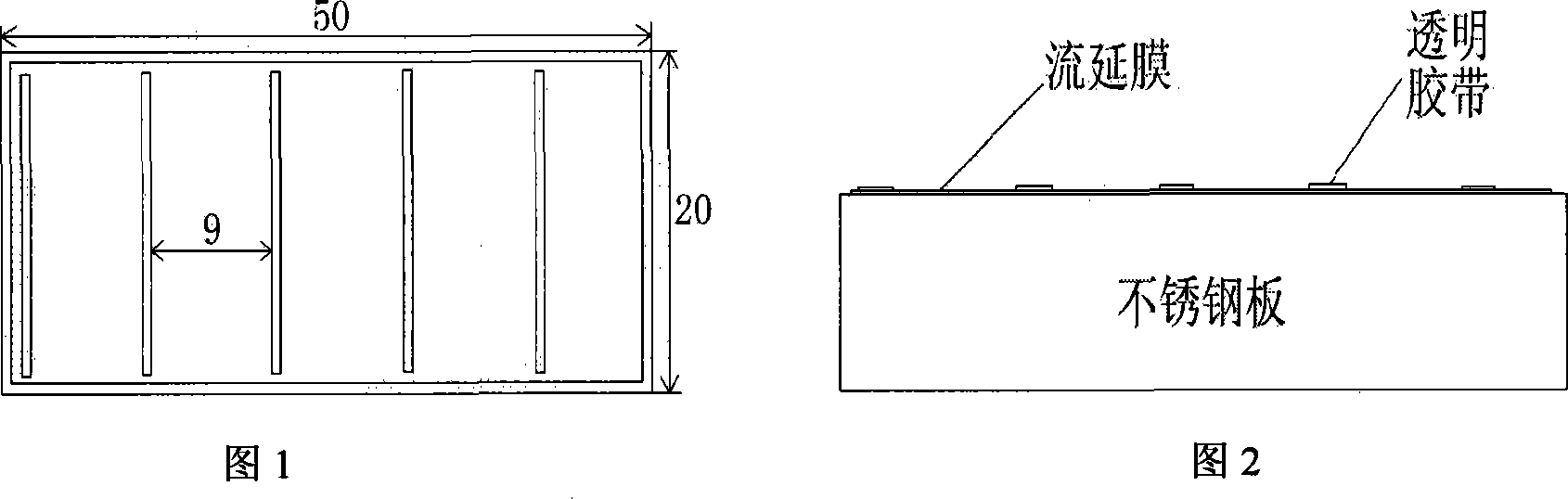

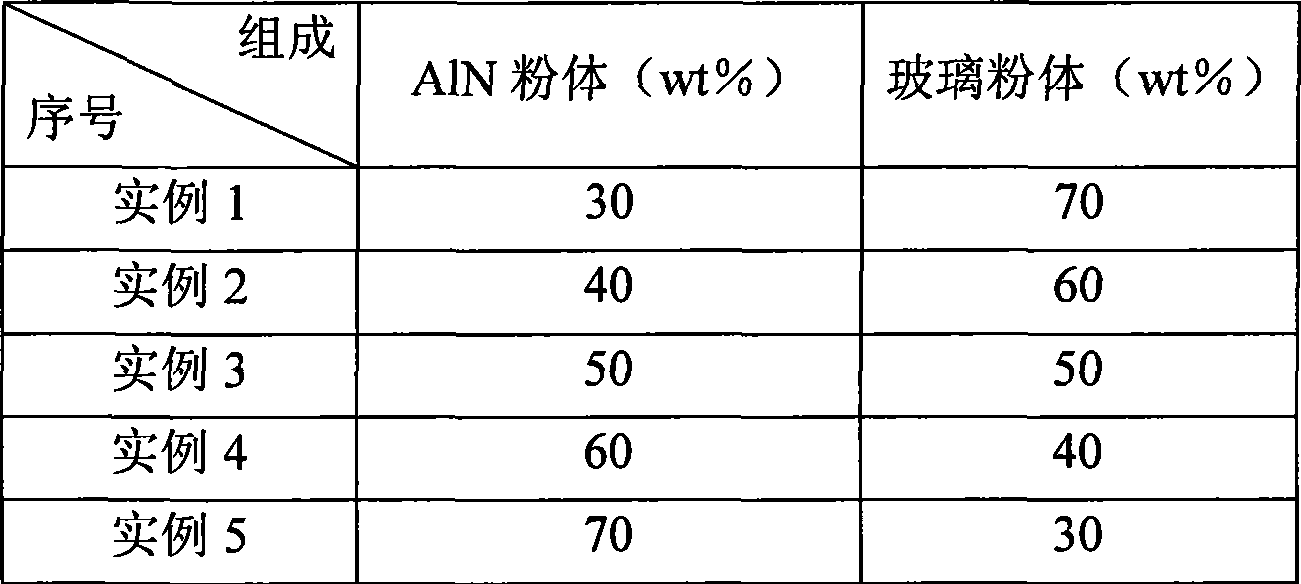

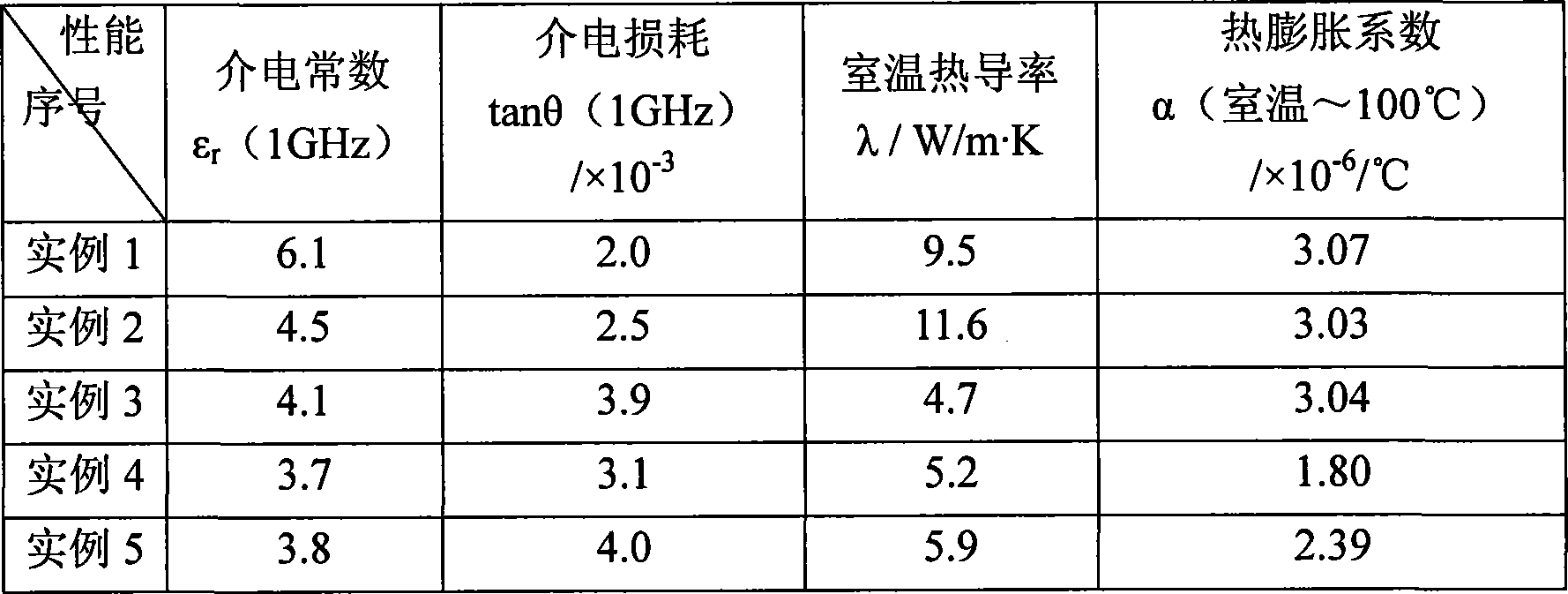

[0037] The present invention will be further described below in conjunction with examples. AlN / SiO of the present invention 2 -B 2 O 3 -ZnO-Al 2 O 3 -Li 2 O low-temperature co-fired ceramic substrate material formulations are shown in Table 1 and Table 2.

[0038] Table 1 Glass formula

[0039] Oxide name

SiO 2

B 2 O 3

ZnO

Al 2 O 3

Li 2 O 3

Mole percentage

12%

24%

54%

5%

5%

[0040] Table 2 Substrate material formula

[0041] Table 3 Performance parameters of AlN powder

[0042] Purity

Total oxygen content

Average particle size

Specific surface area

>99.0%

<40ppm

<0.8%

0.5μm

>10.2m 2 / g

0.13g / cm 3

Exterior color

Decomposition temperature

Dielectric constant

Off-white

3.26g / cm 3

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com