Dead steam reclaiming method and equipment thereof

A waste steam recovery and equipment technology, applied in lighting and heating equipment, drying, furnace types, etc., can solve the problems of wasting heat, not easy to recycle, pollute the environment, etc., and achieve the effect of increasing power load and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

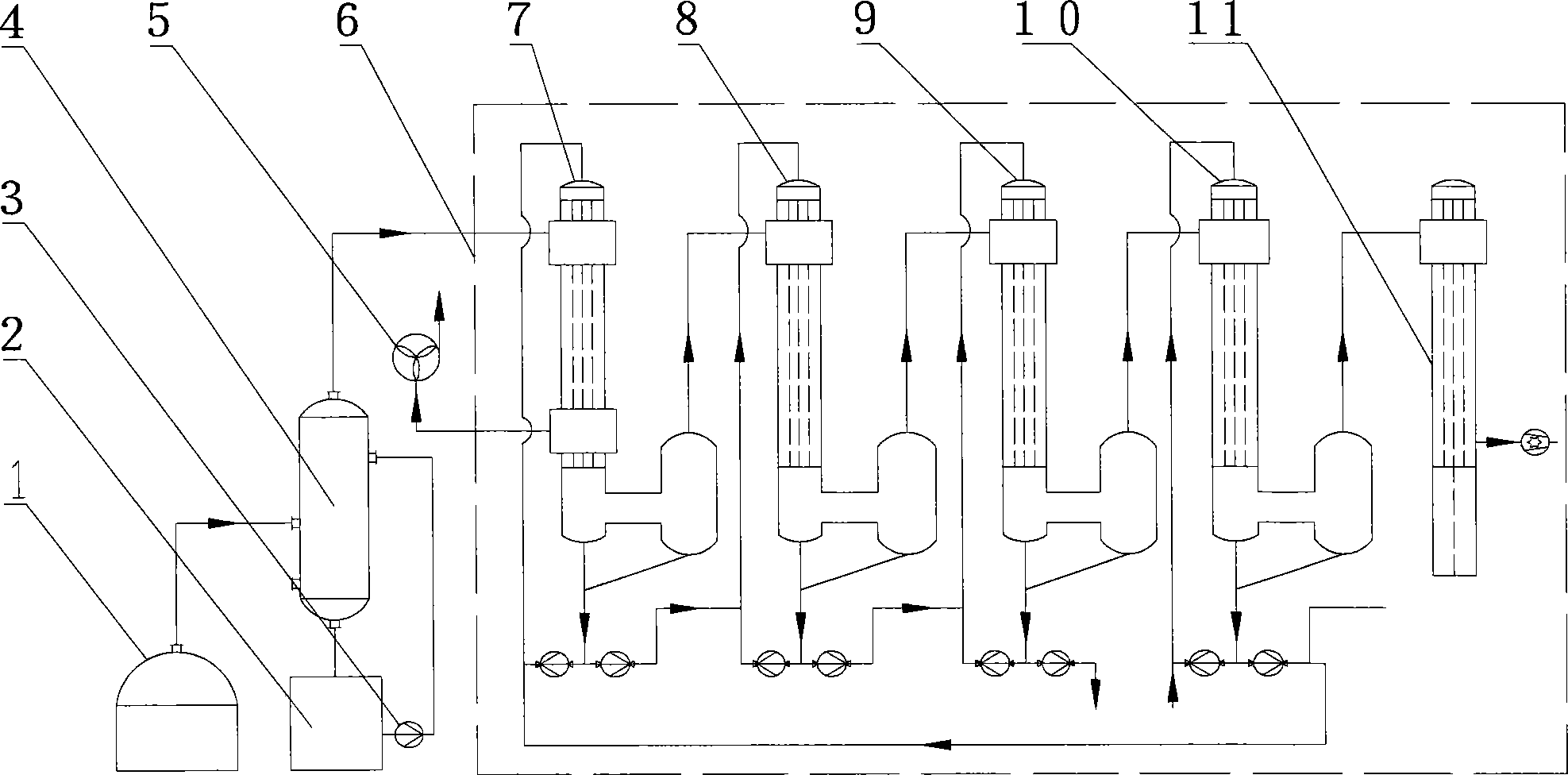

[0019] As shown in the drawings: the present invention includes a tube bundle dryer 1, a steam washing tower 4, corn steep liquor concentration equipment 6, a waste steam outlet is provided on the tube bundle dryer 1, and corn steep liquor concentration equipment includes a zero-effect evaporator 7, one-effect evaporation器8, two-effect evaporator 9, three-effect evaporator 10, condenser 11. The tube bundle dryer 1 is provided with an exhaust gas outlet, the top of the steam scrubber 4 is provided with a steam outlet, and the bottom of the tower is provided with a water outlet, the upper part of the steam scrubber 4 is provided with a water inlet, and the lower part is provided with a steam inlet , Sewage outlet, the exhaust steam outlet on the tube bundle dryer 1 is connected to the steam inlet on the steam scrubber 4 through the pipeline, and the steam outlet on the steam scrubber 4 is connected to the zero effect of the corn steeping equipment 6 through the pipeline The shell si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com