Electric welding rod automatic dryer

A technology for welding electrodes and dryers, applied in dryers, drying, progressive dryers, etc., can solve problems such as heat loss, energy waste, inconvenient installation and maintenance, etc., to reduce heat loss and save energy , Easy installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

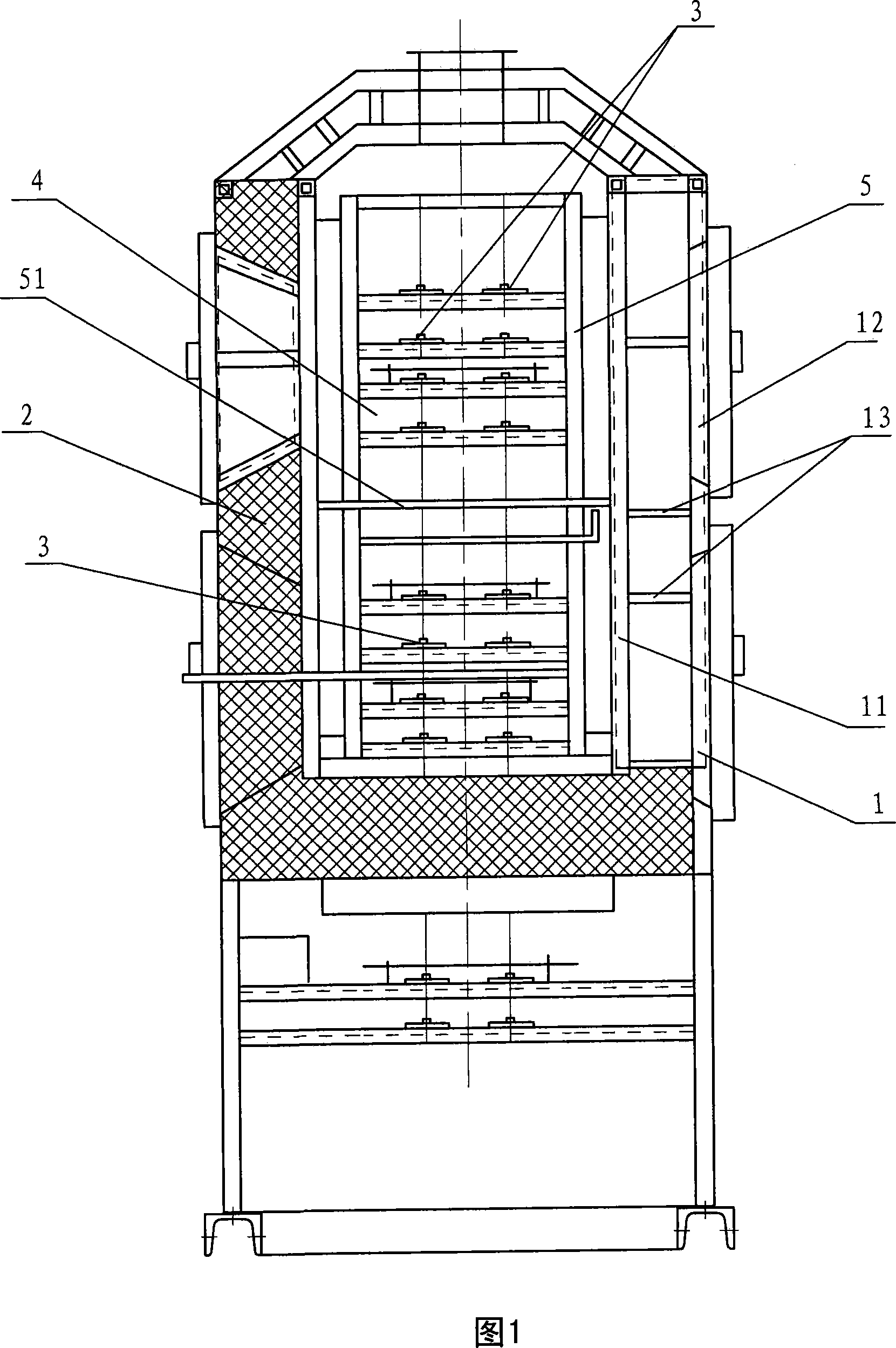

[0009] As shown in the figure, the furnace body of the welding rod drying furnace of the present invention includes a metal frame 1 and a refractory insulation material 2 filled in the metal frame. The metal frame is composed of an inner frame 11 and an outer frame 12, two layers The frames are connected and fixed by connecting bridges 13 arranged at intervals. A movable frame 5 that can be removed from the furnace body is arranged in the heating chamber 4 in the furnace body. A multi-layer conveying track 3 for transporting welding electrodes is installed on the movable frame. The heating chamber is divided into upper and lower parts by a partition 51 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com