Conveying belt part, method for making belt data for conveying belt part and method for making conveying belt part

A production method and conveyor belt technology, applied in the direction of electrical components, electrical components, packaging, etc., can solve the problems of low operating rate of installation devices, prevent the reduction of operating efficiency, reduce the number of times to replace conveyor belts, and improve efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

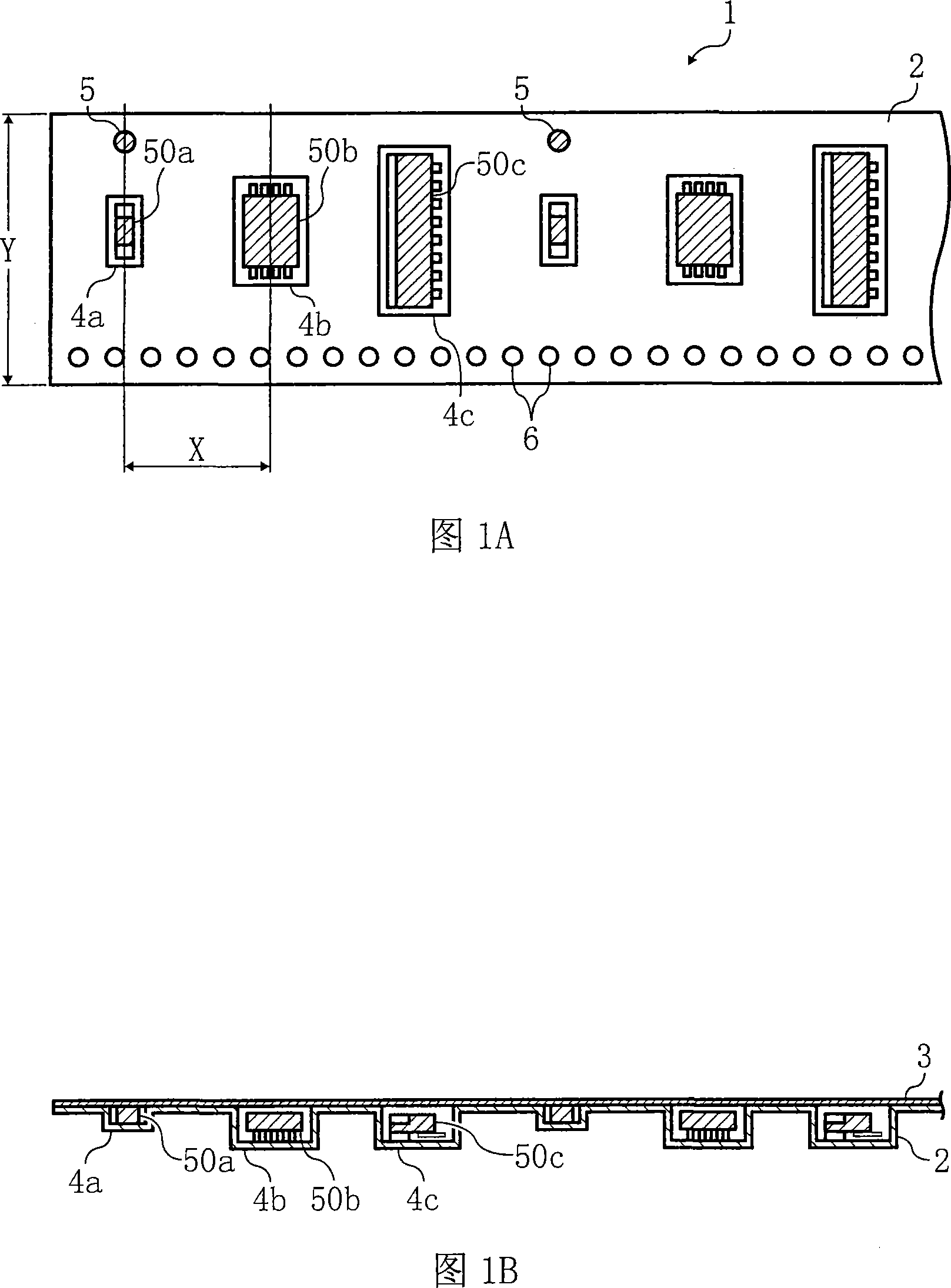

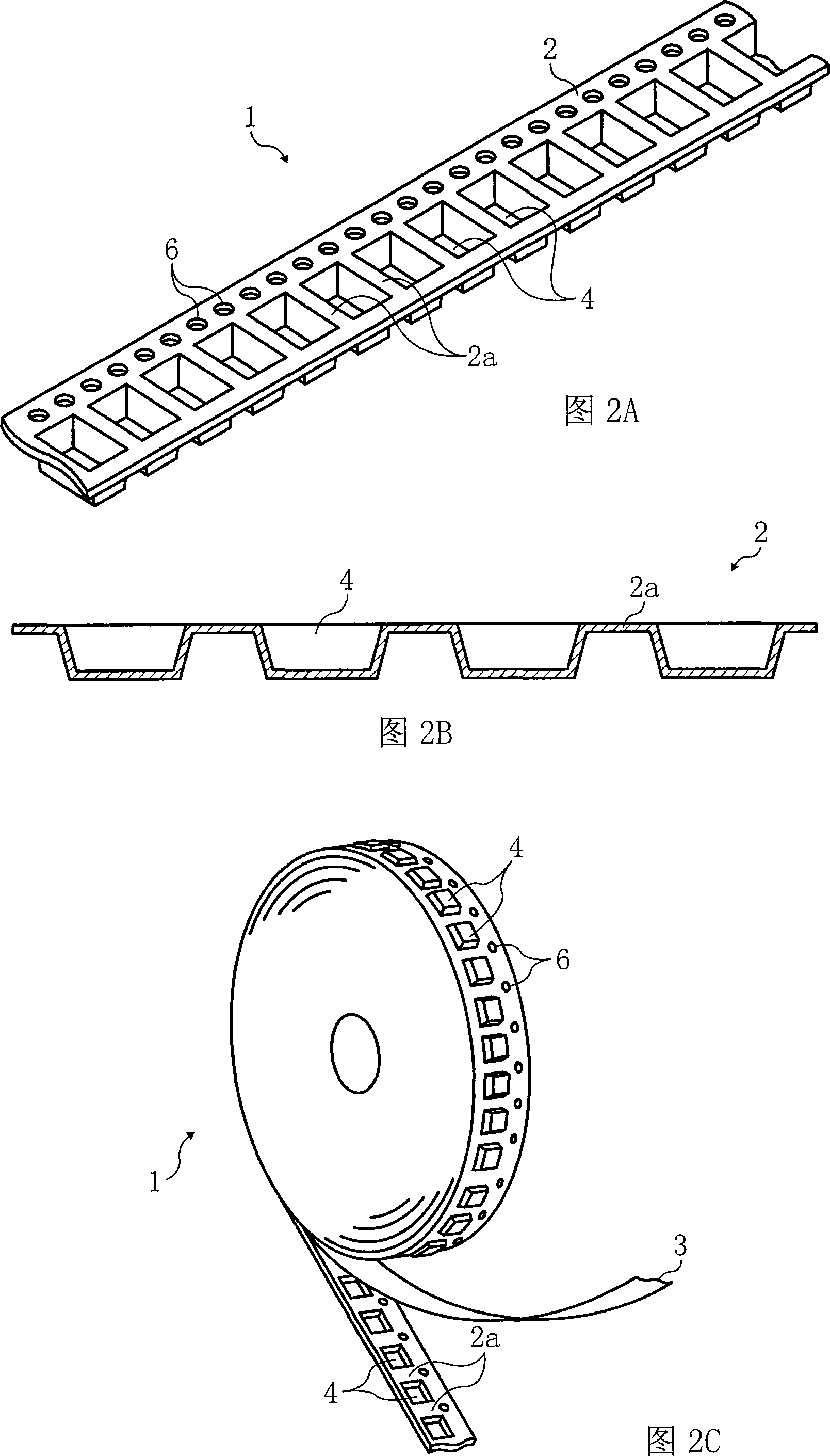

[0048] 1A and 1B are structural diagrams of a conveyor belt member according to a first embodiment of the present invention. FIG. 1A is a plan view; FIG. 1B is a cross-sectional view. In addition, the cover tape is omitted in FIG. 1A .

[0049]The conveyor belt member 1 shown in FIGS. 1A and 1B is composed of a carrier belt 2 and a cover belt 3 covering the carrier belt 2 . On the carrier tape 2, there are storage portions 4a, 4b, and 4c that can respectively store various electronic components 50a, 50b, and 50c to be mounted on a printed circuit board. The storage parts 4a, 4b and 4c correspond to the stored electronic components 50a, 50b and 50c, and have different shapes. The structure of the conveyer belt member 1 comprised in this way is a reel which can be wound up. That is, the carrier tape 2 and the cover tape 3 can be wound together.

[0050] Generally spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com