Method for preparing polyphenylene oxide sulfide

A technology of polyphenylene ether and dihalogenated diphenyl sulfide, which is applied in the field of preparation of polyphenylene ether sulfide, can solve the problems of low melting point of PPSE, poor PPSE purity, long reaction time, etc., and achieves easy raw materials and short polymerization reaction time. , good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

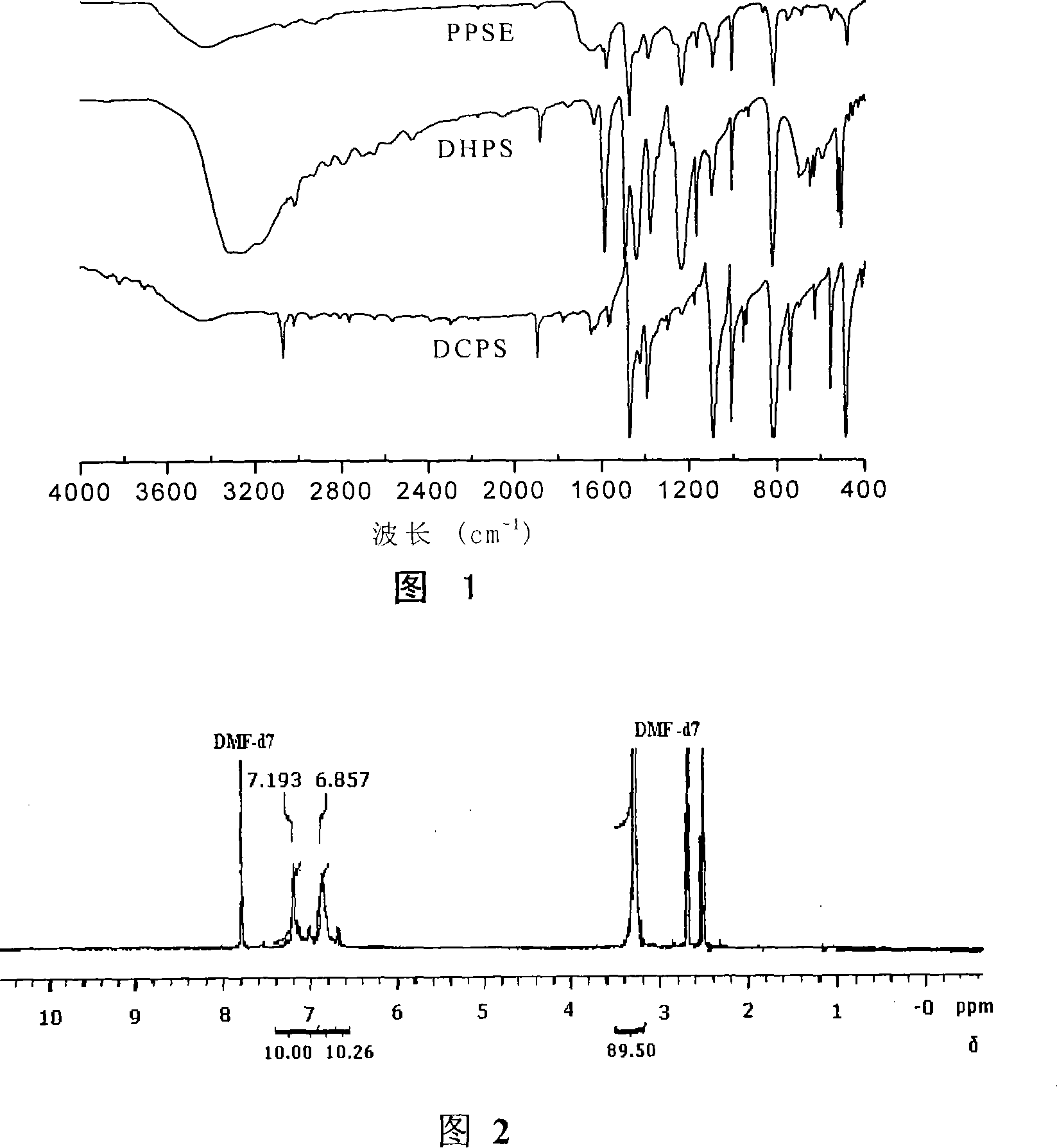

[0041] 1. Raw material and its formula

[0042] Reactive monomer 4,4'-dihydroxydiphenyl sulfide (DHPS) 109g (0.5mol)

[0043] Reactive monomer 4,4'-dichlorodiphenylsulfide (DCPS) 127.5g (0.5mol)

[0044] Anhydrous Na 2 CO 3 21.2g (0.2mol)

[0045] Anhydrous K 2 CO 3 55.2g (0.4mol)

[0046] Sodium benzoate 7.5g (0.052mol)

[0047] Zinc powder 6.5g (0.1mol)

[0048] Sulfolane 200mL

[0049] Toluene 100mL

[0050] 2. Process steps

[0051] (1) Polymerization reaction

[0052] Under the protection of nitrogen at room temperature (28 ° C), the above reaction monomer 4,4'-dihydroxydiphenyl sulfide and 4,4'-dichlorodiphenyl sulfide, auxiliary agent anhydrous Na 2 CO 3 and anhydrous K 2 CO 3 , composite catalyst sodium benzoate and zinc powder, solvent sulfolane, and azeotropic dehydrating agent toluene are added to the reaction kettle equipped with agitator, thermometer, and water separator, and the temperature is raised to 140 ° C ~ 150 ° C under stirring. Azeotropic ...

Embodiment 2

[0056] 1. Raw material and its formula

[0057] Reactive monomer 4,4'-dihydroxydiphenyl sulfide (DHPS) 109g (0.5mol)

[0058] Reactive monomer 4,4'-dichlorodiphenylsulfide (DCPS) 127.5g (0.5mol)

[0059] Anhydrous Li 2 CO 3 60g (0.81mol)

[0060] Trisodium phosphate 8.2g (0.05mol)

[0061] Hydrazine hydrate 10mL (0.2mol)

[0062] Cuprous oxide 7.2g (0.05mol)

[0063] N,N'-Dimethylacetamide 250mL

[0064] Chlorobenzene 100mL

[0065] 2. Process steps

[0066] (1) Polymerization reaction

[0067] Under the protection of nitrogen at room temperature (25 ° C), the above reaction monomer 4,4'-dihydroxydiphenyl sulfide and 4,4'-dichlorodiphenyl sulfide, auxiliary agent anhydrous Li 2 CO 3 , the composite catalyst trisodium phosphate, hydrazine hydrate and cuprous oxide, the solvent N, N'-dimethylacetamide, and the azeotropic dehydrating agent chlorobenzene are added to the reaction kettle equipped with a stirrer, a thermometer and a water separator. Under stirring, heat ...

Embodiment 3

[0071] 1. Raw material and its formula

[0072] Reactive monomer 4,4'-dihydroxydiphenyl sulfide (DHPS) 109g (0.5mol)

[0073] Reactive monomer 4,4'-dichlorodiphenylsulfide (DCPS) 127.5g (0.5mol)

[0074] KOH 72.8g (1.3mol)

[0075] Sodium acetate 10g (0.12mol)

[0076] Hydrosulfite 5.2g (0.03mol)

[0077] N,N'-Dimethylformamide 350mL

[0078] Xylene 200mL

[0079] 2. Process steps

[0080] (1) Polymerization reaction

[0081] Under nitrogen protection at room temperature (21 ° C), the above reaction monomer 4,4'-dihydroxydiphenyl sulfide and 4,4'-dichlorodiphenyl sulfide, auxiliary agent KOH, composite catalyst sodium acetate and sodium hydrochloride , the solvent N, N'-dimethylformamide, and the azeotropic dehydrating agent xylene are added to a reaction kettle equipped with a stirrer, a thermometer, and a water separator, and the temperature is raised to 140°C to 150°C under stirring to azeotropically reflux, Azeotropic reflux for 4 hours (moisture and azeotropic deh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com