Technique for forming rubber dam

A molding process and rubber dam technology, which is applied to household components, household appliances, and other household appliances, can solve the problems of high probability of water seepage, difficulty of leveling, and affecting the overall appearance of the rubber dam, so as to achieve easy leveling, The effect of uniform force and reducing the chance of water seepage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

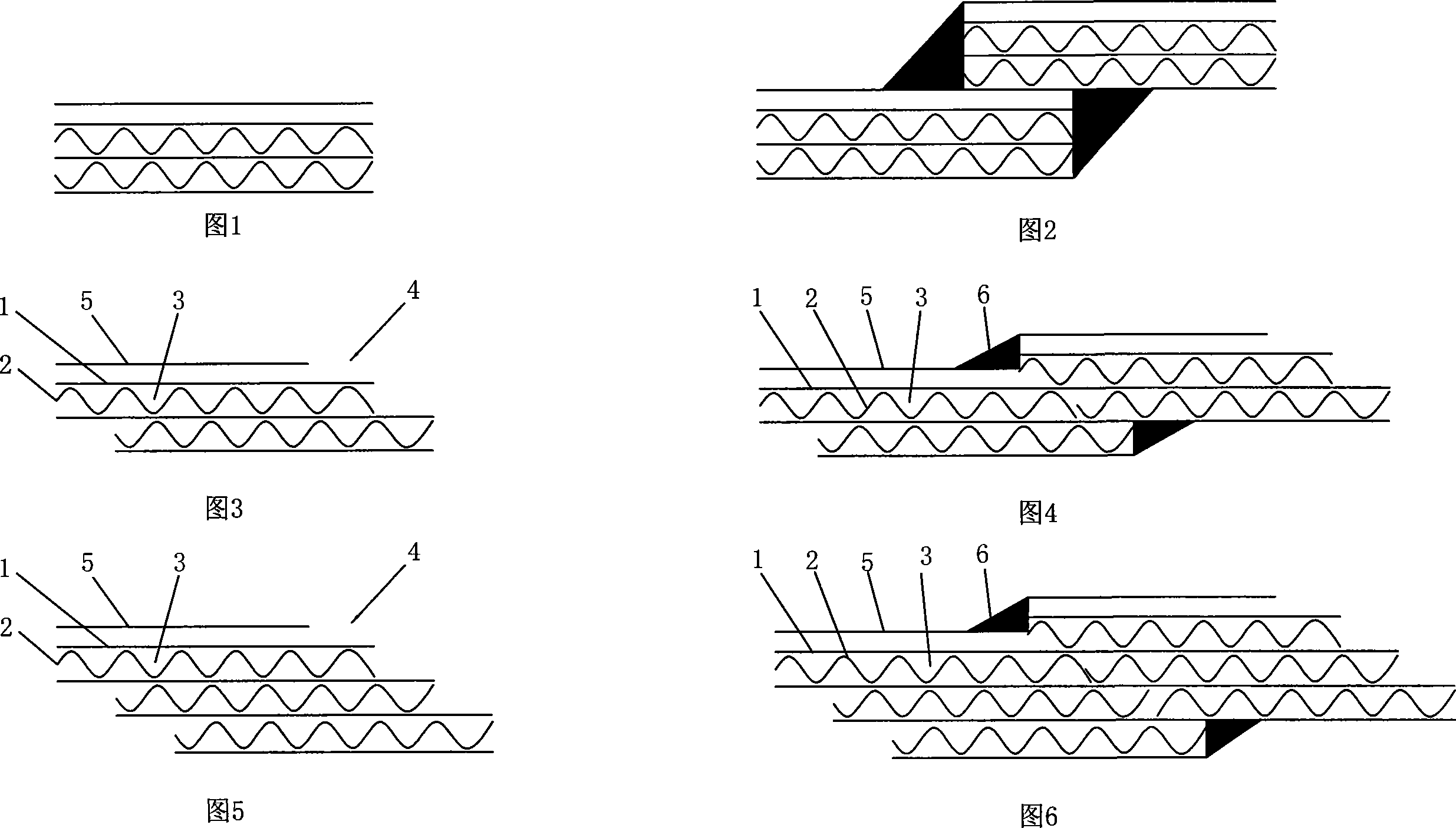

[0020] As shown in Figures 3 and 4, the molding process of the rubber dam according to the present invention is as follows: the rubber 1, the canvas 2, and the rubber are arranged and calendered at intervals up and down to form the rubber cloth 3, and the two layers of the rubber cloth 3 are staggered and formed in different stages to form the dam piece 4 , the upper part of the dam piece 4 is also calendered with an outer glue 5, one end of the dam piece 4 is a step-shaped seam, and the other end is an inverted step-shaped seam, in order to reduce the thickness of the seam, cut off the seam In order to make the dam piece bond firmly, the outer layer glue 5 of the dam piece is roughened at the seam, and the dam piece 4 is relatively overlapped and vulcanized successively to form a rubber dam. In order to make the sealing effect of the rubber dam better, a sealing rubber strip 6 is pasted on the outside of the seams of two adjacent dam pieces.

Embodiment 2

[0022] As shown in Figures 5 and 6, the rubber dam molding process of the present invention is as follows: arrange the rubber 1, the canvas 2, and the rubber at intervals up and down to form the rubber cloth 3, and arrange the two layers of the rubber cloth 3 in a staggered manner to form the dam piece 4 , the upper part of the dam piece 4 is also calendered with an outer glue 5, one end of the dam piece 4 is a step-shaped seam, and the other end is an inverted step-shaped seam, in order to reduce the thickness of the seam, cut off the seam The outer layer of glue 5, in order to make the dam sheet bonded firmly, can roughen the overlapping seams, and the dam sheet 4 is relatively overlapped and vulcanized successively to form a rubber dam. In order to make the sealing effect of the rubber dam better, a sealing rubber strip 6 is pasted on the outside of the seams of two adjacent dam pieces.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com