Capacity varying type rotary compressor and refrigeration system having the same

A rotary compressor and capacity-type technology, applied in the field of rotary compressors, can solve the problems of increasing refrigerant flow resistance, reducing cooling efficiency, complex installation process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Reference will now be made in detail to the preferred embodiments of the invention, examples of which are illustrated in the accompanying drawings.

[0024] Hereinafter, a variable displacement rotary compressor according to the present invention will be described in more detail with reference to one embodiment of the accompanying drawings.

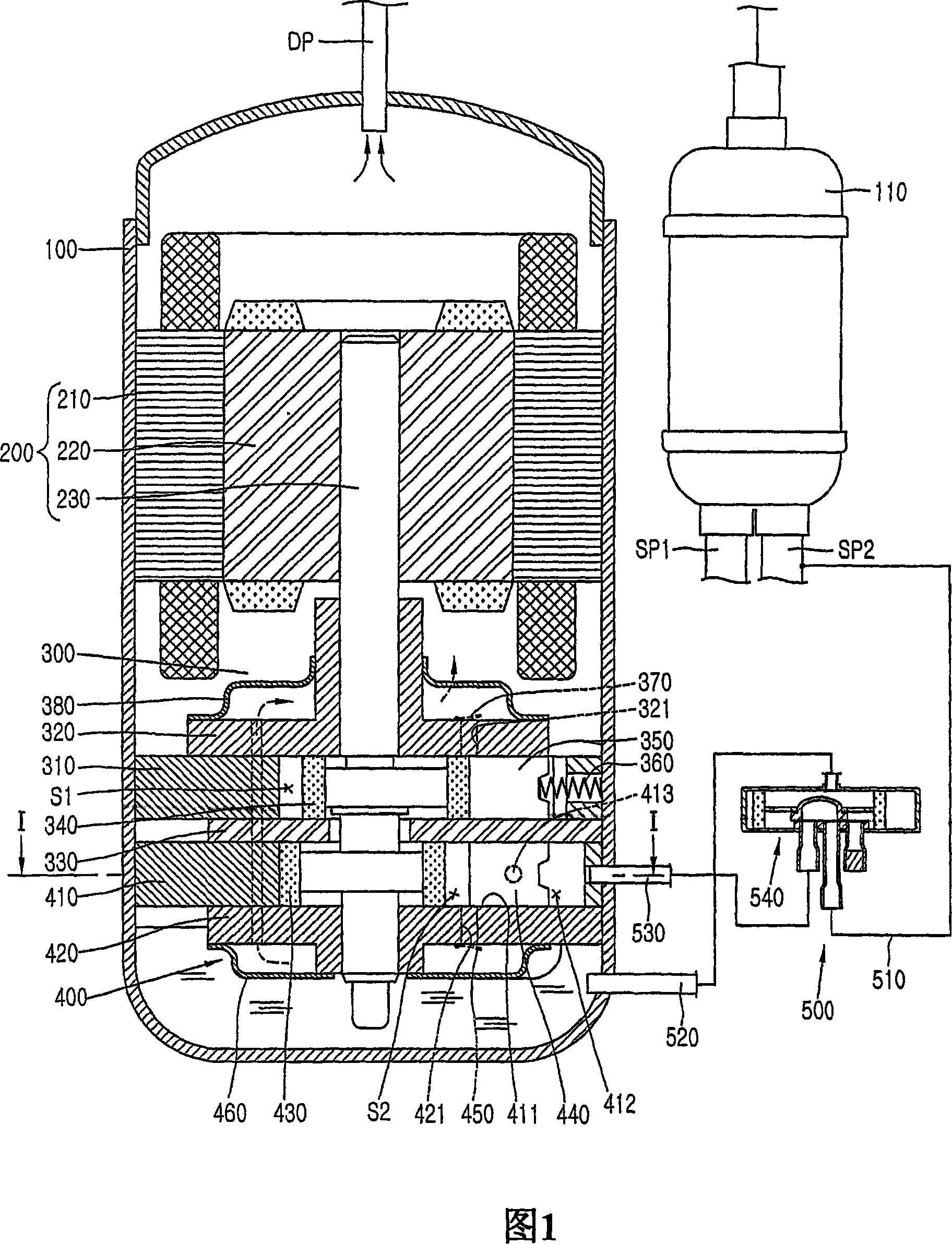

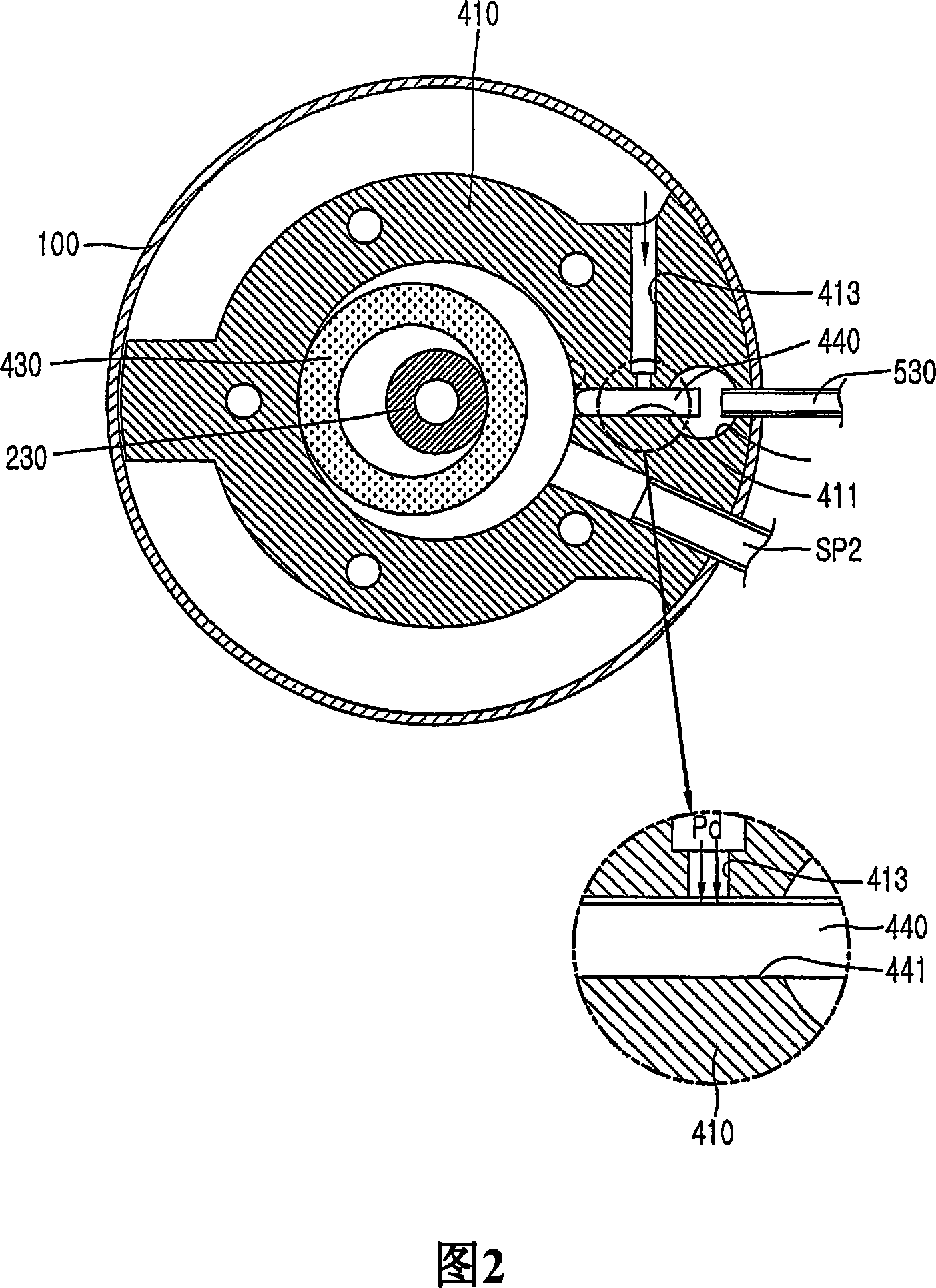

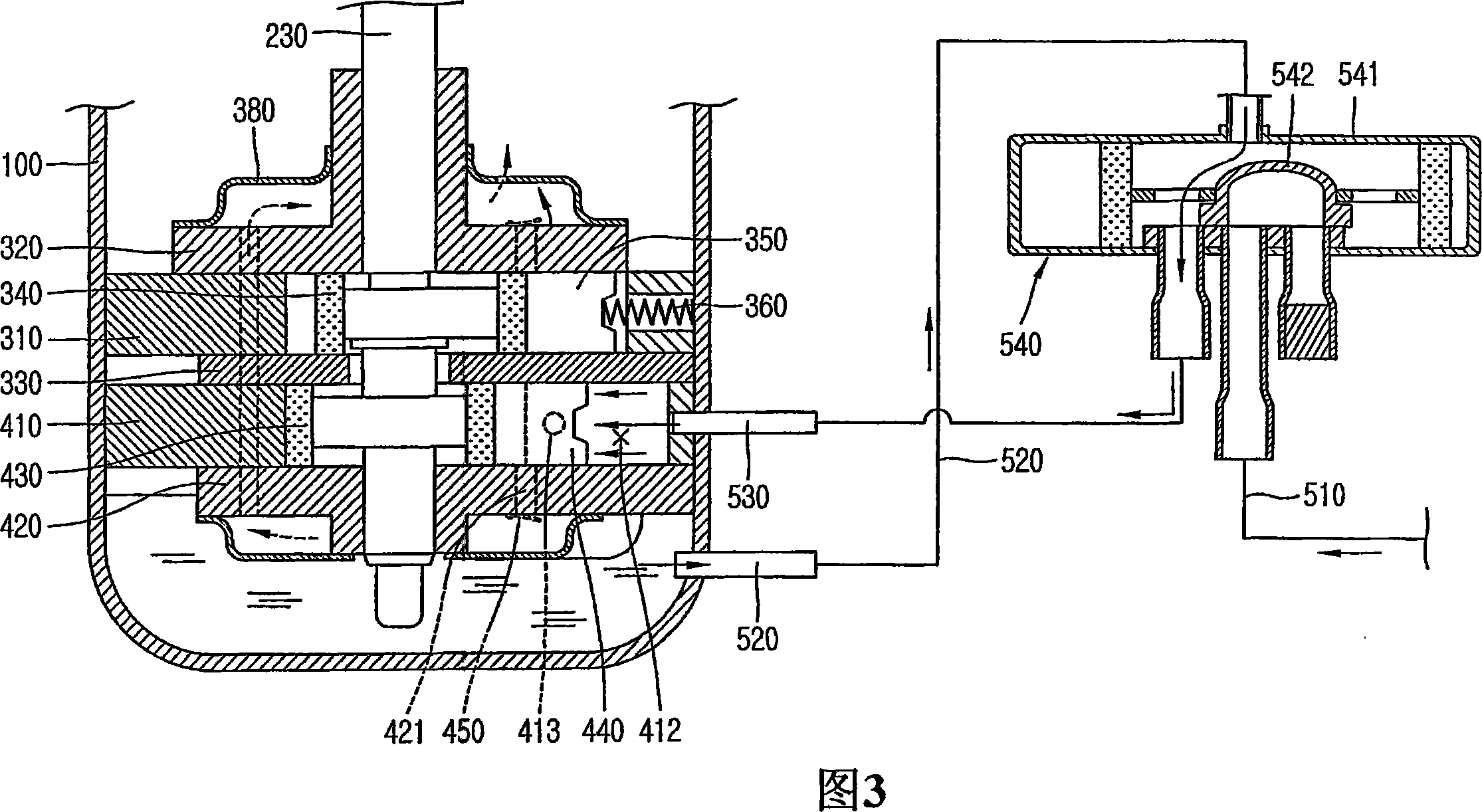

[0025] Fig. 1 is a longitudinal sectional view showing a variable capacity rotary compressor according to the present invention, Fig. 2 is a sectional view taken along line I-I of Fig. to limit the normal drive and energy-saving drive of the blades of the variable displacement rotary compressor according to the present invention; and FIG. example.

[0026] As shown in Figure 2, compound rotary compressor according to the present invention comprises: casing 100, a plurality of gas suction pipes SP1 and SP2 and a gas discharge pipe DP are connected to this casing 100; Motor part 200, it is installed in casing 100 and generate rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com