Multi-branch gas sampling pipe

A technology of gas sampling tubes and sampling tubes, applied in the direction of sampling devices, etc., can solve the problems of inconvenient calibration work, lengthened pipelines, increased gas pressure, etc., to achieve easy inspection and cleaning, reduce measurement errors, and reduce uncertainties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

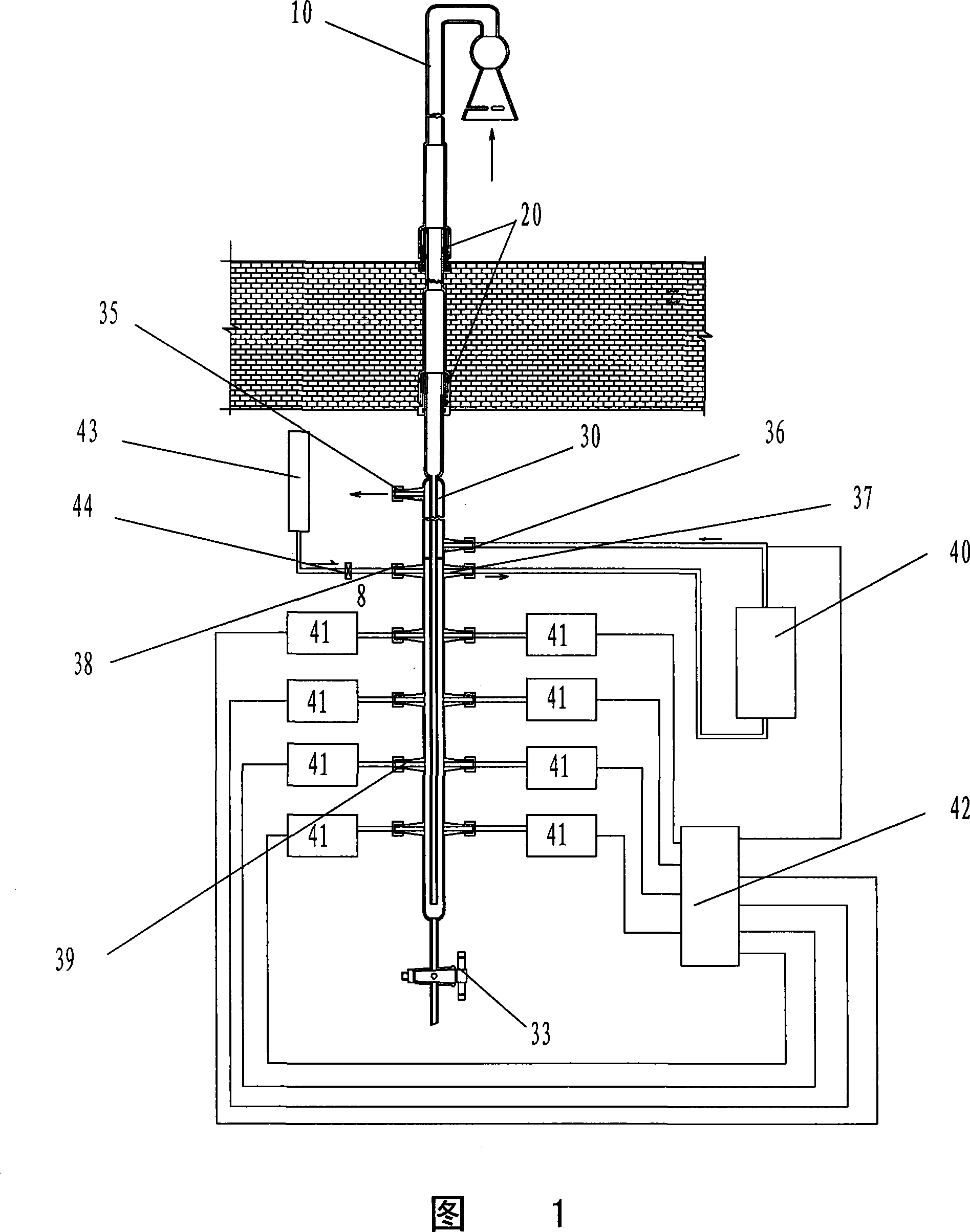

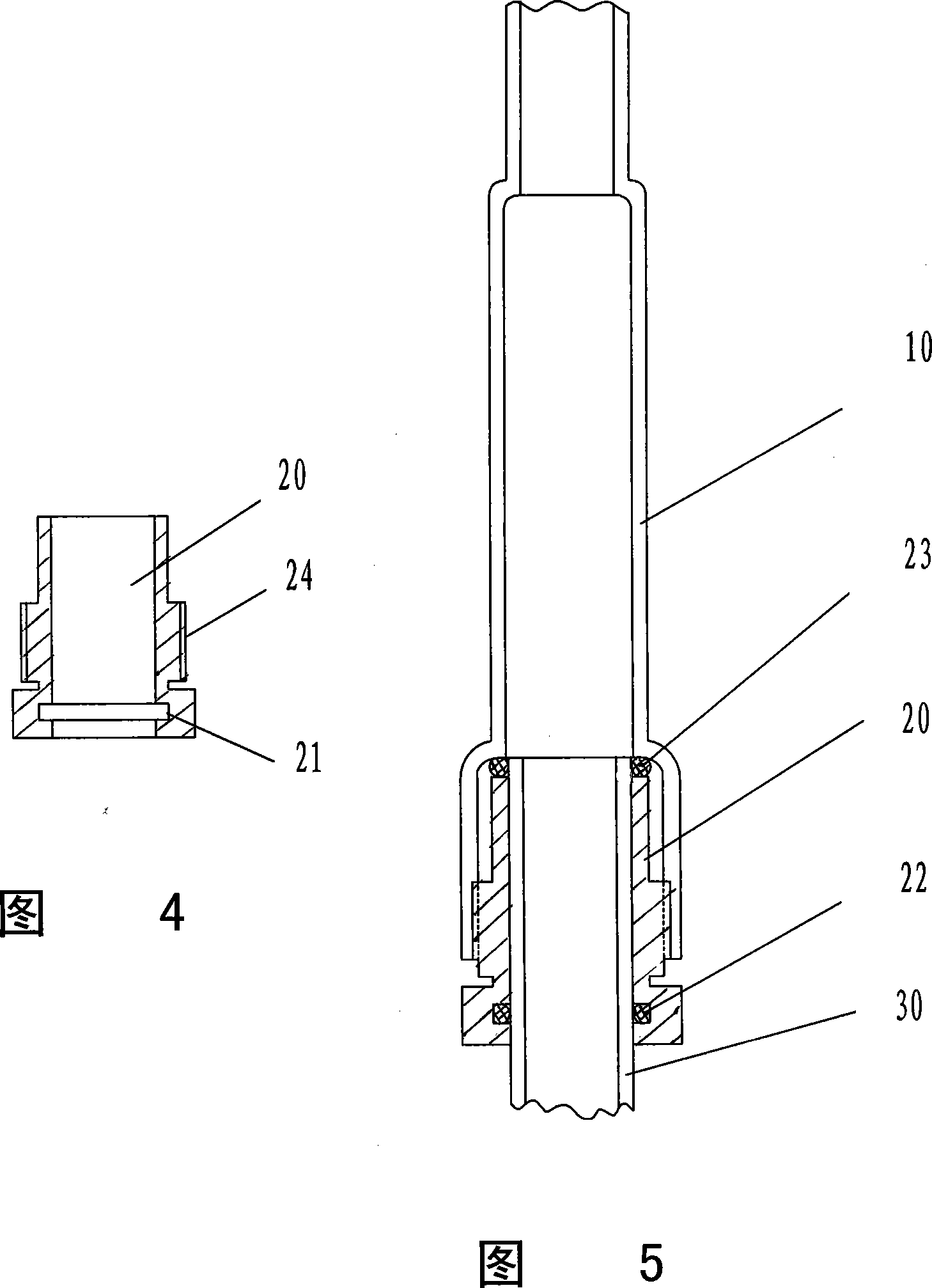

[0019] As shown in FIG. 1 , the multi-branch gas sampling tube of the present invention is mainly composed of three parts: a front-end sampling tube 10 , a pipe joint 20 and a main sampling tube 30 .

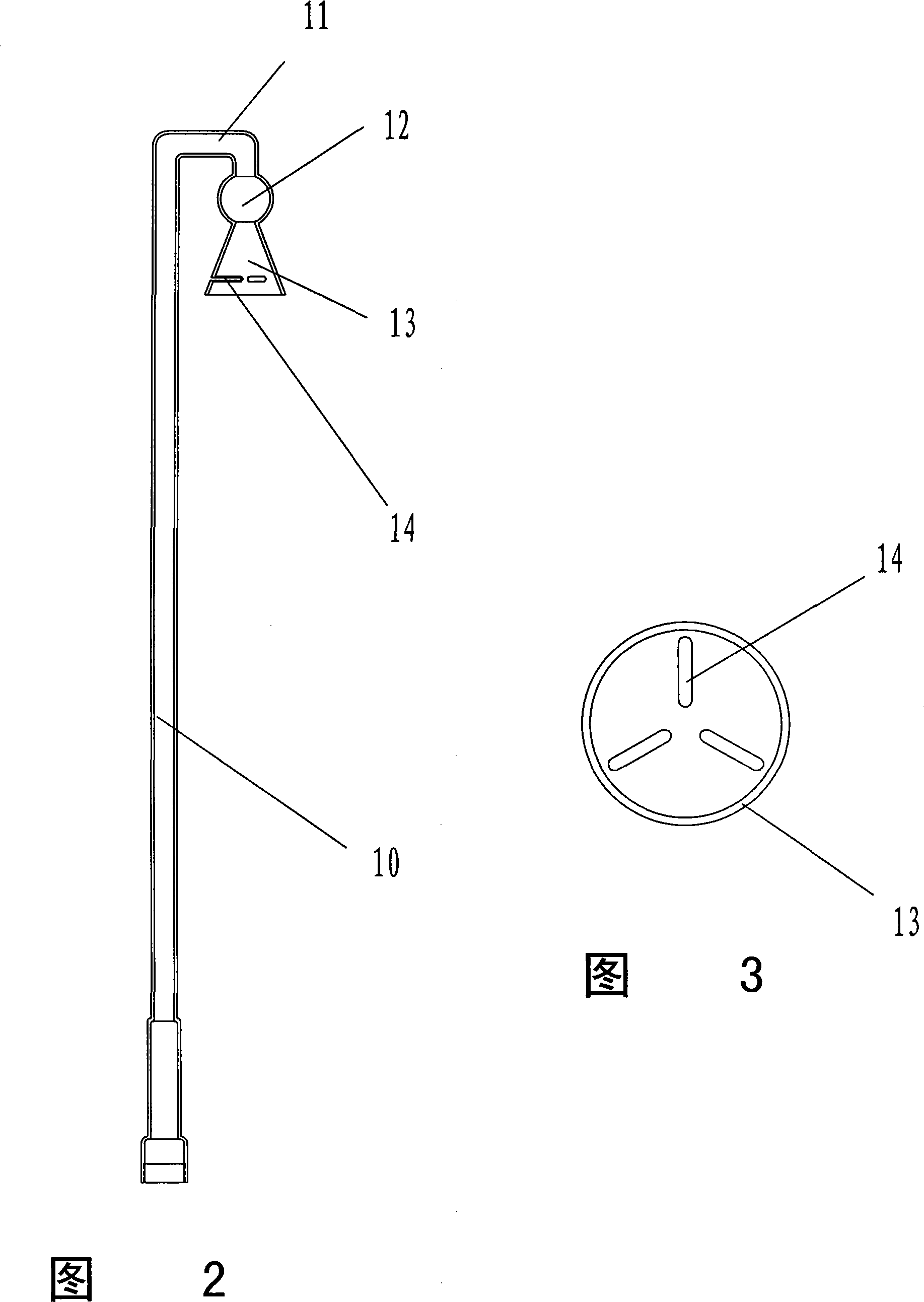

[0020] As shown in Fig. 1, Fig. 2 and Fig. 3, the front-end sampling pipe 10 made of glass material of the present invention refers to the pipeline above the main sampling pipe 30, which can be a pipe or a pipe joint 20 connected tube above the root. The uppermost end of the front-end sampling pipe is a U-shaped curved pipe 11, and the end of the curved pipe 11 is connected to an umbrella-shaped air inlet 13 through a spherical joint 12. Three to four ribs are arranged on the inner side of the umbrella-shaped air inlet 13, and the curved pipe 11 and the effect of umbrella-shaped air inlet 13 are rainproof and dustproof, and can prevent larger solid was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com