Deep rock mass engineering project disaster model experiment method

A technology of model experiment and rock mass, which is applied in the field of model test for experimental research and deep rock mass engineering disaster model experiment, can solve the problems of long period and high cost, and achieve the goal of ensuring accuracy, overcoming high cost and enriching loading methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Test content

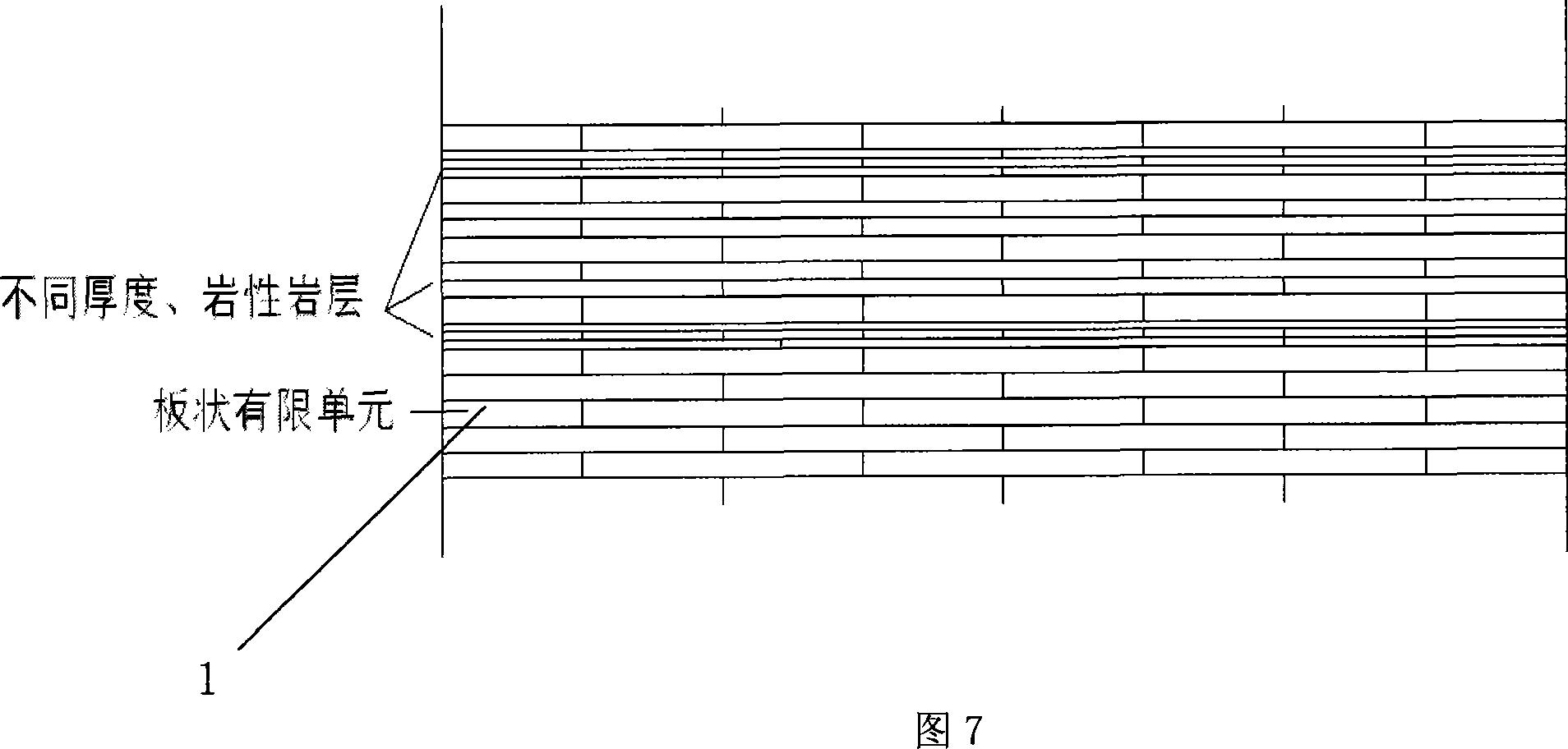

[0029] 1) On the basis of the conception of physical finite element plates in geomechanical model tests proposed by Professor He Manchao of China University of Mining and Technology, study how to prepare physical finite element plates, and improve the existing model test methods and technologies;

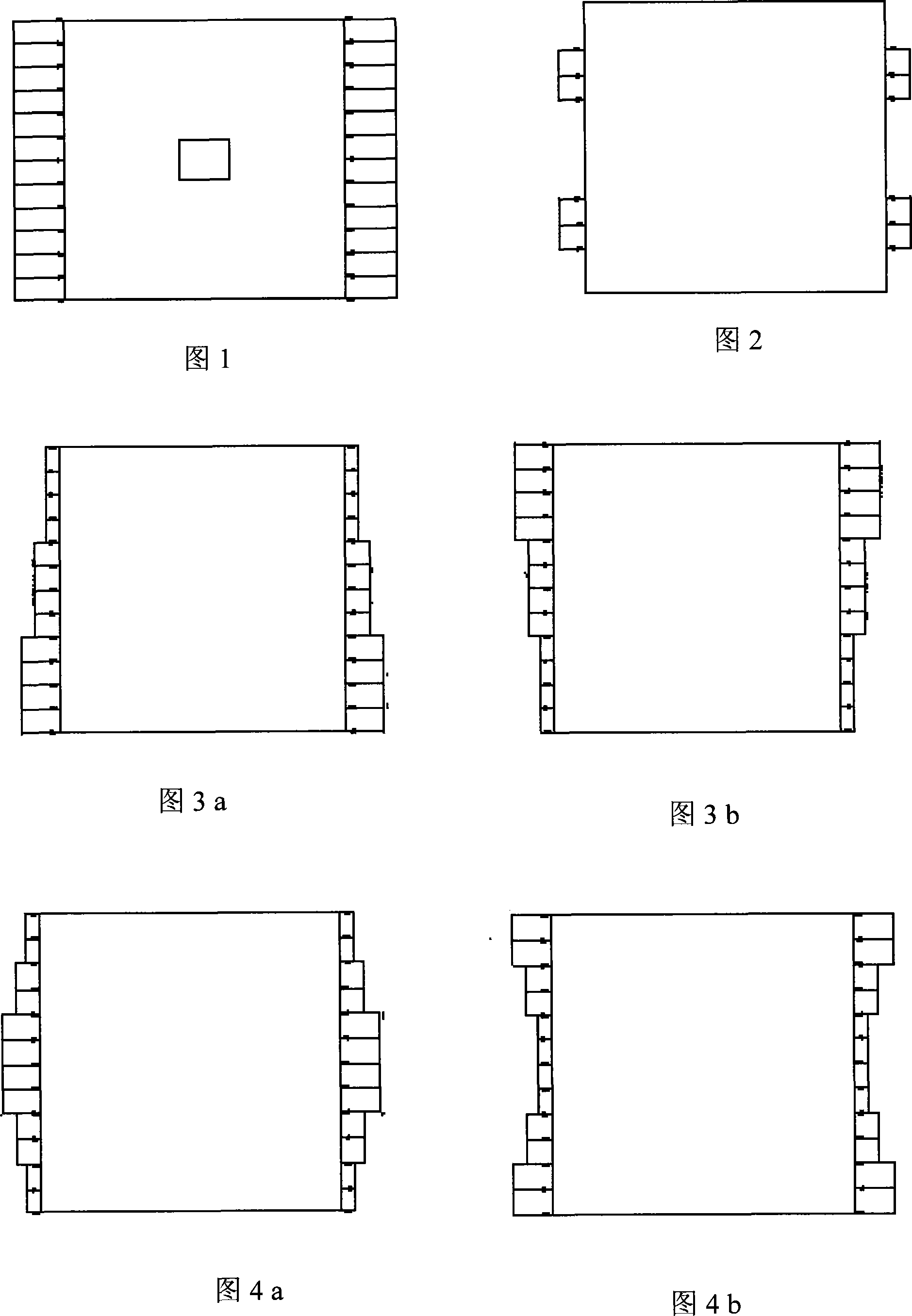

[0030] 2) Use the test equipment adopted by the rock mass engineering and geological disaster simulation test system (China University of Geosciences, Beijing) to carry out different boundary (mainly lateral) loading methods on the large-scale model samples made of physical finite element plates. Under the plane test, the impact of the boundary loading plate on the loading accuracy and the deformation law of the deep coal rock under continuous loading and discontinuous loading conditions are discussed;

[0031]Before the excavation of the model, the loading comparison test of the boundary continuous loading plate and the discontinuous loading plate is carried o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com