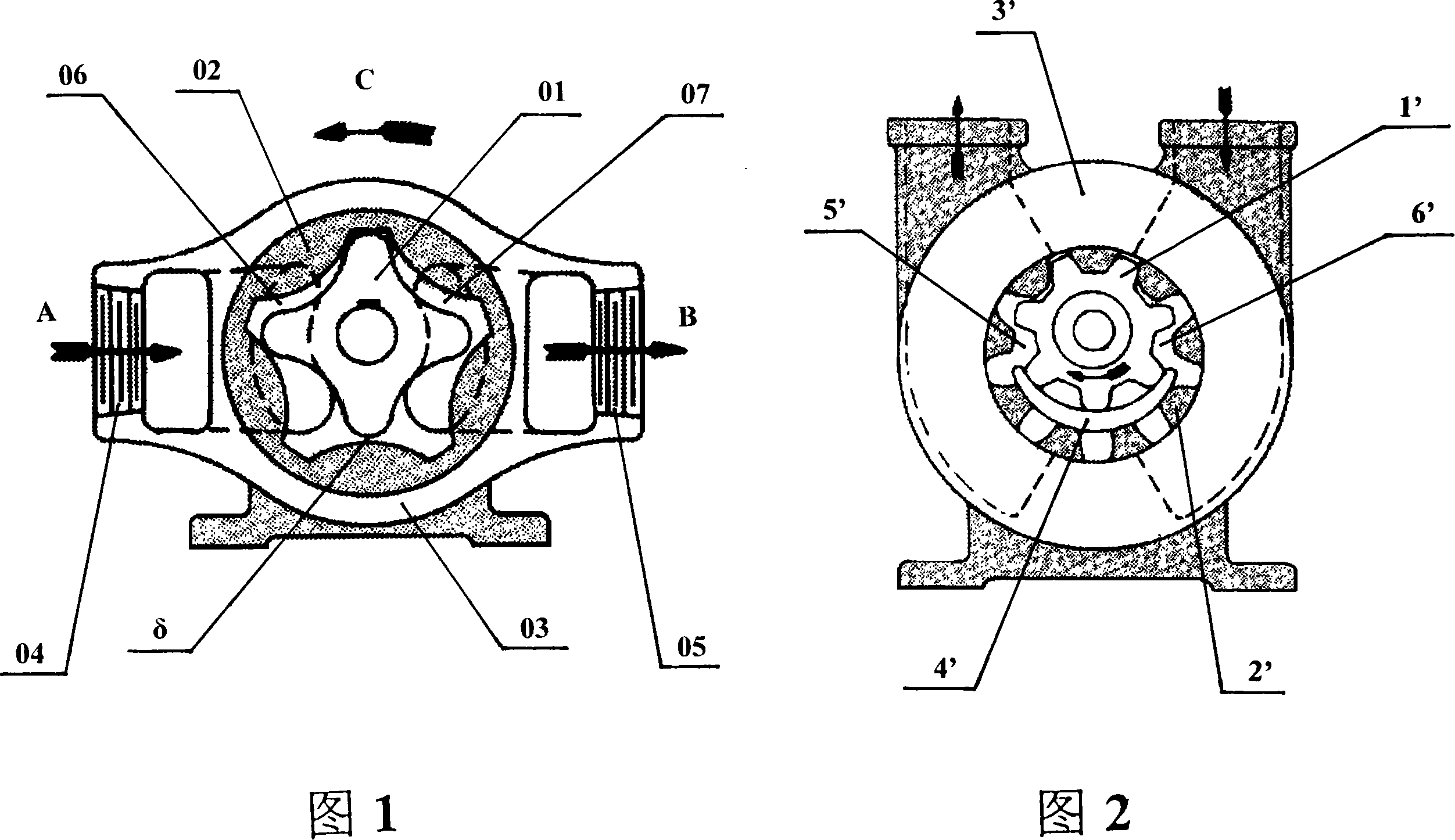

Internal gear rotary pump or motor

An internal gear pump, internal gear technology, applied in the direction of intermeshing engines, pumps, rotary piston pumps, etc., can solve problems such as large leakage, avoid inherent gaps, have a good degree of sealing, and compensate for tooth tip gaps. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

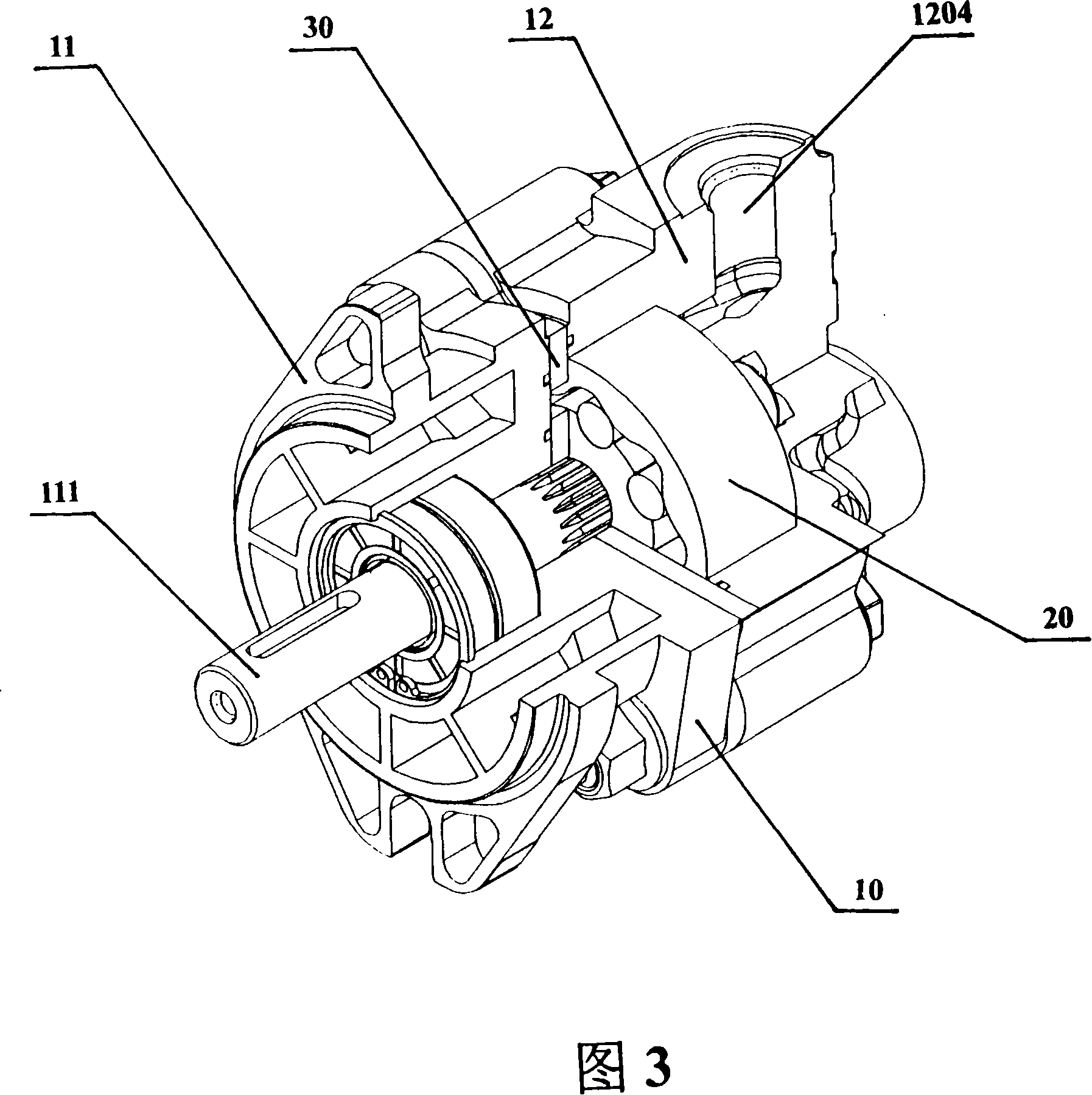

[0030] The present invention will now be described in further detail in conjunction with the accompanying drawings and embodiments.

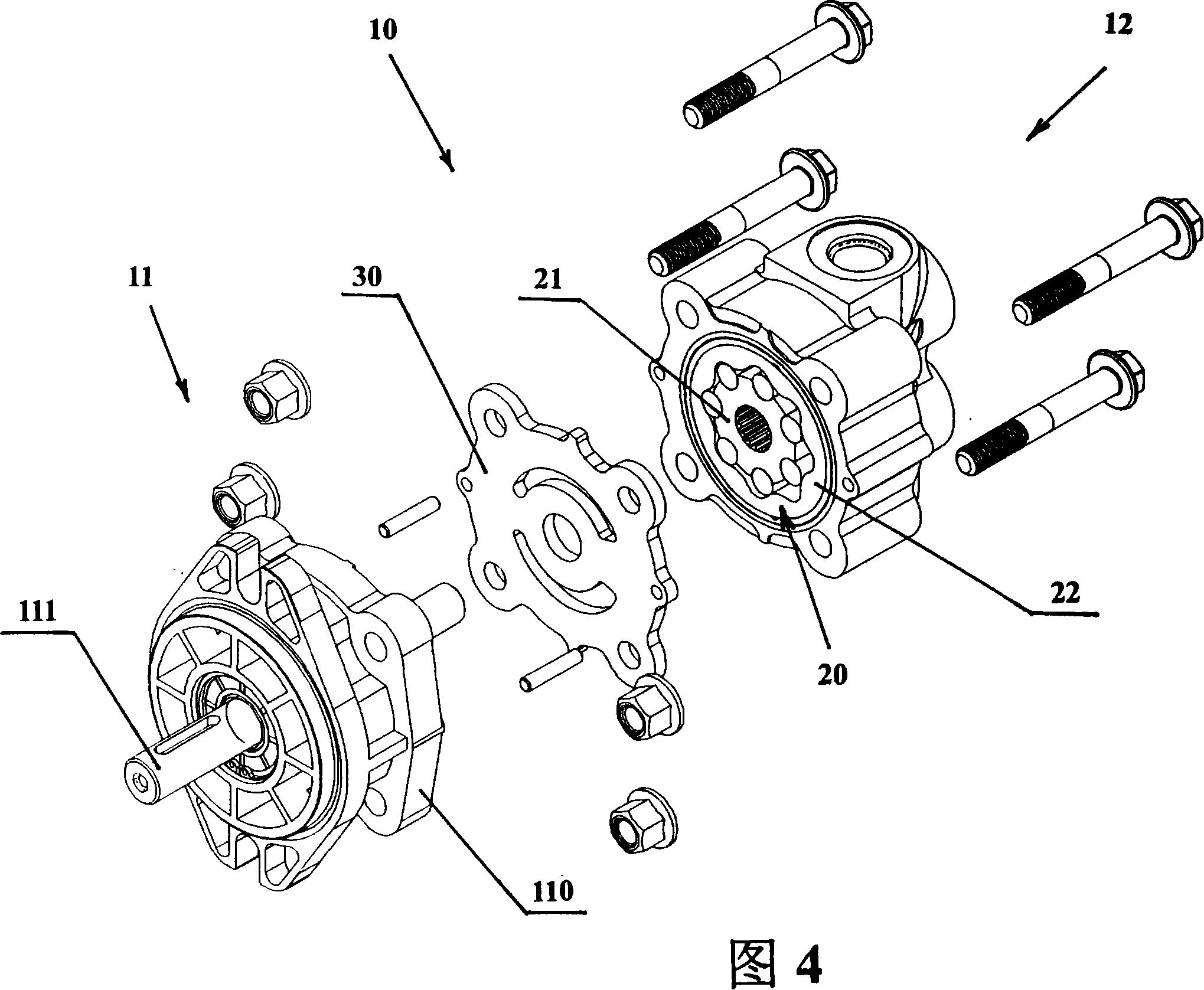

[0031] Please refer to FIG. 3 and FIG. 4 for structural diagrams of the present invention, which illustrate that the internal meshing gear pump includes a housing part 10 , an internal meshing gear pair 20 and a flexible side plate 30 .

[0032] The housing part 10 consists of a front housing part 11 and a rear housing part 12 . Please refer to FIG. 5 for an exploded structural view of the front housing part 11 , the front housing part 11 includes a front housing 110 , an input shaft 111 and a front bearing 112 . The front housing 110 has a central hole 1101 and an inner end surface 1102 perpendicular to the axis of the central hole 1101; the input shaft 111 penetrates the central hole 1101 and is mounted on the front housing 110 through the front bearing 112. In the central hole 1101; please refer to Fig. 8 for the longitudinal sectional view ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com