Device for prolonging the lifetime of resistance spot welding electrode

An electrode and resistance technology is applied in the field of resistance spot welding electrode life extension device to achieve the effect of reducing alloying and improving electrode life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The following is divided into three parts. That is, the mechanical structure of the device, the movement process and the selection of copper sheets.

[0037] (1) Mechanical structure

[0038] The device is divided into two parts corresponding to the upper and lower electrodes, that is, the part connected with the upper electrode and the part connected with the lower electrode.

[0039] Upper electrode part:

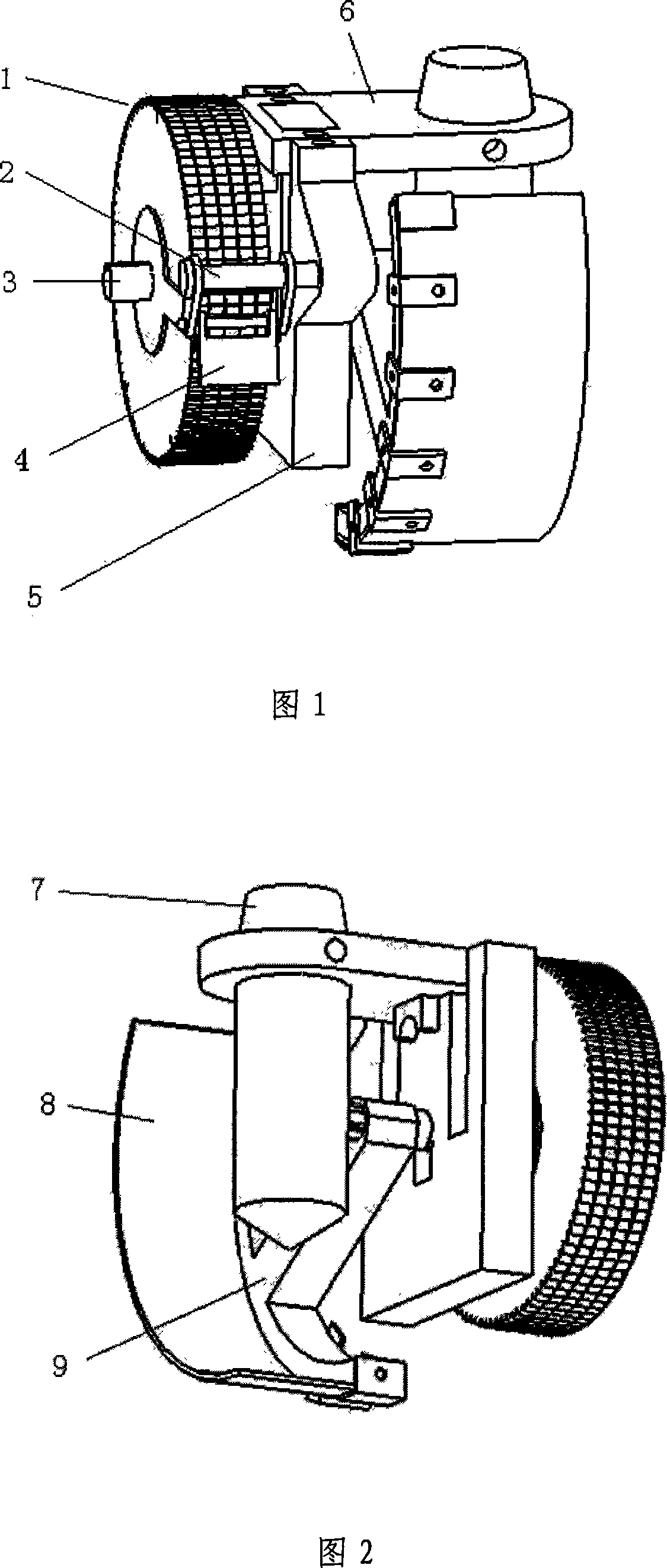

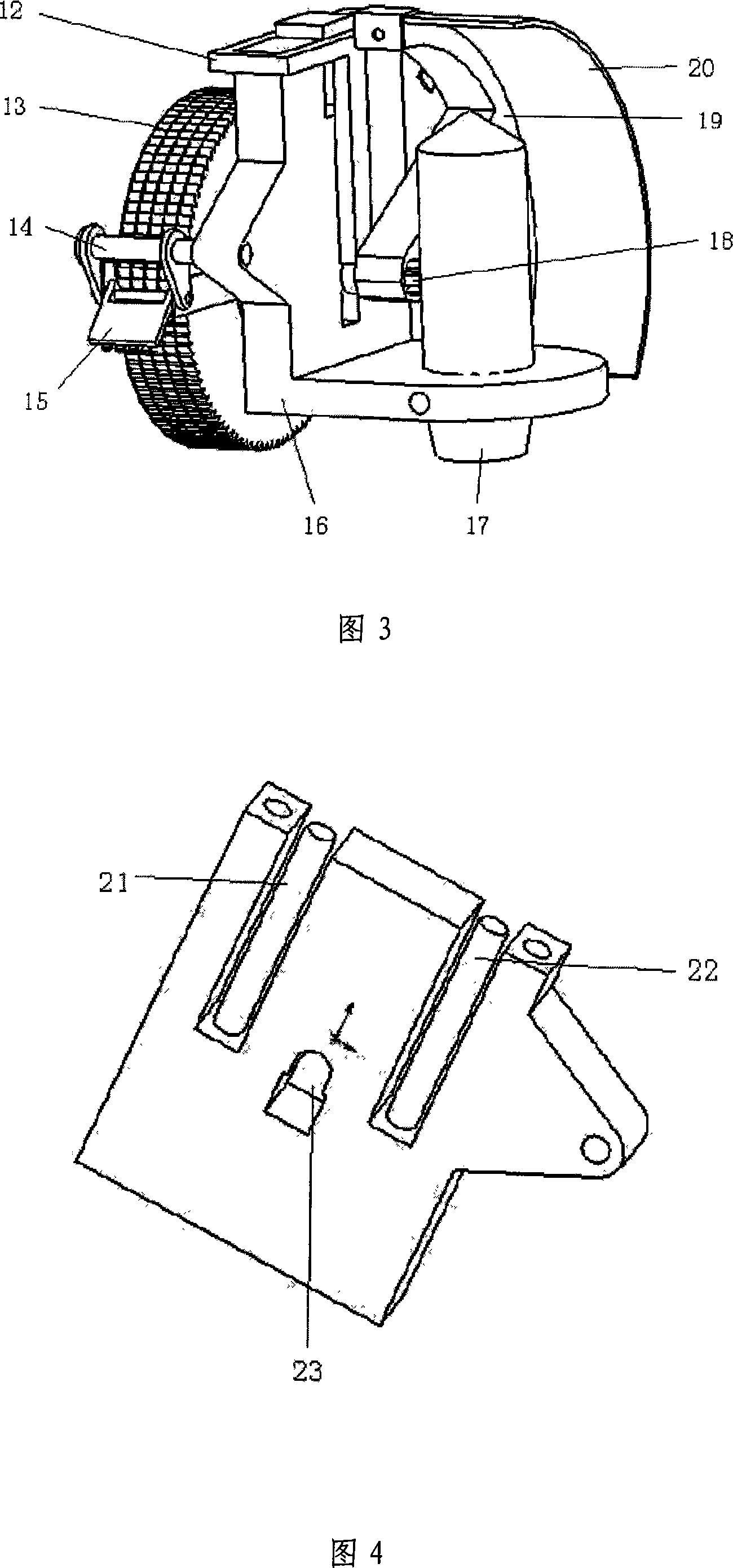

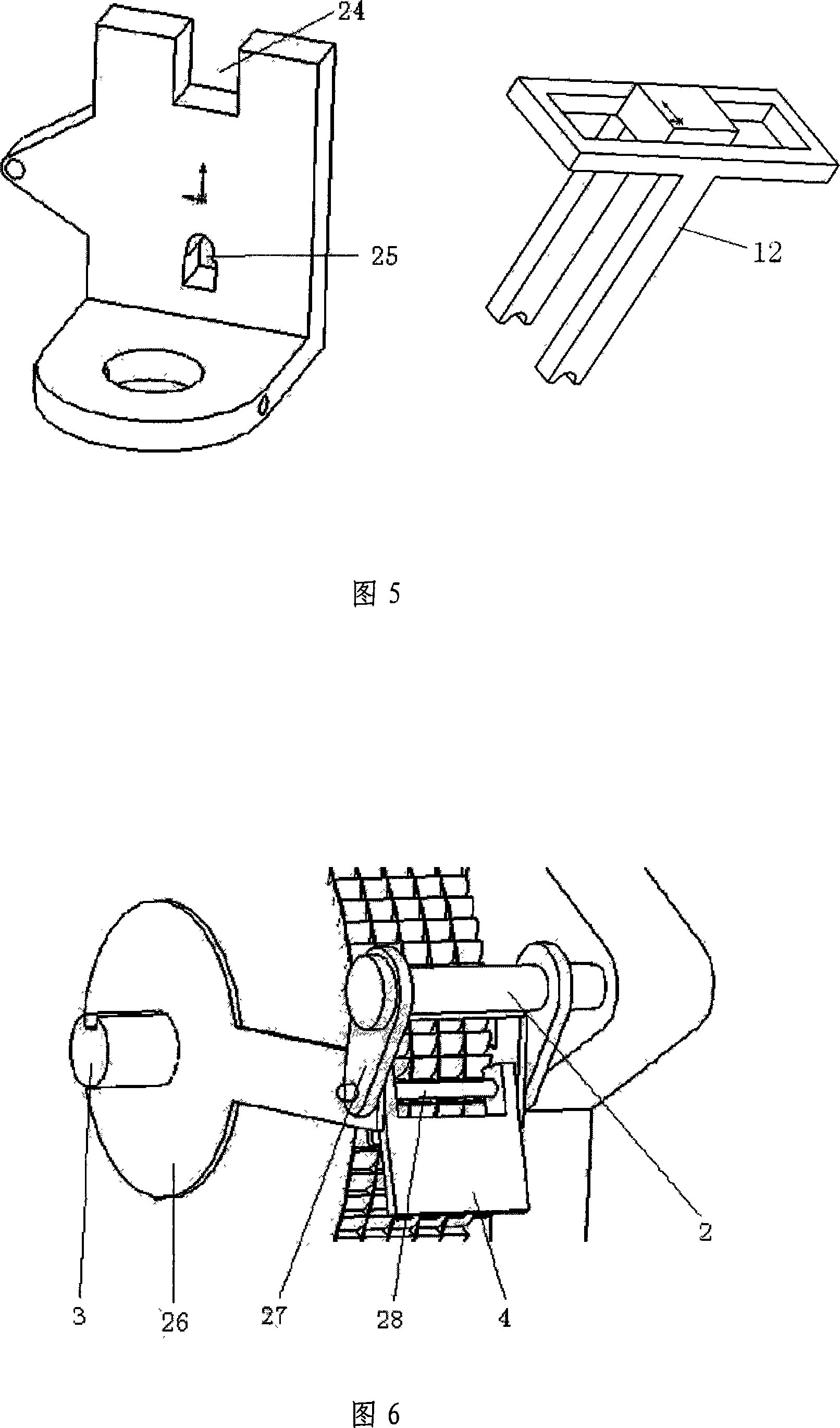

[0040] Referring to Fig. 1, Fig. 2 and Fig. 4, the part connected with the upper electrode includes: the upper movable support 6 fixedly connected with the upper electrode 7, the upper support 5 fixedly connected with the welding machine, and the upper movable support 6 and the upper support 5 are Flexible connection, upper bracket 5 is symmetrically provided with two rectangular grooves at one end away from the workpiece, and a spring column 21, 22 is respectively fixed in the rectangular groove, and a spring is set on the spring column; the depth of the rectang...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com