Method for fabricating field emitter electrode using array of carbon nanotubes

A technology of emitting electrodes and carbon nanotubes, applied in the direction of oriented carbon nanotubes, discharge tube/lamp manufacturing, nanotechnology, etc., can solve insurmountable problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Embodiment 1: Preparation of carbon nanotubes

[0054] 500 mg of carbon nanotubes were placed in a furnace at 365° C., where they were heat-treated for 90 minutes while 0.1 SLM (standard liter per minute) of air was injected into the furnace. The heat-treated carbon nanotubes were added to 500 ml of hydrochloric acid, sonicated for 1 hour, and filtered through a filter. Afterwards, the filtered carbon nanotubes were added to 500 ml of hydrochloric acid, sonicated for 1 hour, and filtered through a 1-μm filter. Repeat the hydrochloric acid treatment process 3-5 times to purify the carbon nanotubes. Also, pictures by a transmission electron microscope (TEM) show carbon nanotubes before and after the purification treatment (see FIG. 2 ). As a result, as shown in Figure 2, the carbon nanotubes contained impurities before purification (see Figure 2a ), while after purification they are free of impurities (see Figure 2b ). The purified carbon nanotubes were immersed ...

Embodiment 2

[0055] Example 2: Binding Magnetic Particles to Carbon Nanotubes

[0056] 10.8g of ferric chloride (FeCl 3 ·6H 2 O) and 36.5 g of sodium oleate (Cl 8 h 33 NaO 2 ) was added to a mixture of 80 ml of ethanol, 60 ml of distilled water and 140 ml of hexane, and heated at 70° C. for 4 hours, thereby preparing an iron oleate complex. 12 g of the prepared iron oleate complex, 2.83 g of oleic acid, and 3 ml of dimethylformamide (DMF) solvent were mixed with each other, and 150 mg of the carbon nanotubes prepared in Example 1 were dispersed in the mixture.

[0057] Thereafter, the mixture was completely dissolved in 130 ml of 1-octadecene at room temperature, and the mixture was heated to a temperature of 320° C., allowed to react at that temperature for 30 minutes, and then cooled to room temperature. The reaction material was washed 3-4 times with ethanol, centrifuged to remove the supernatant, and then filtered through a 1-μm filter to provide iron oxide (Fe 2 o 3 ) to carb...

Embodiment 3

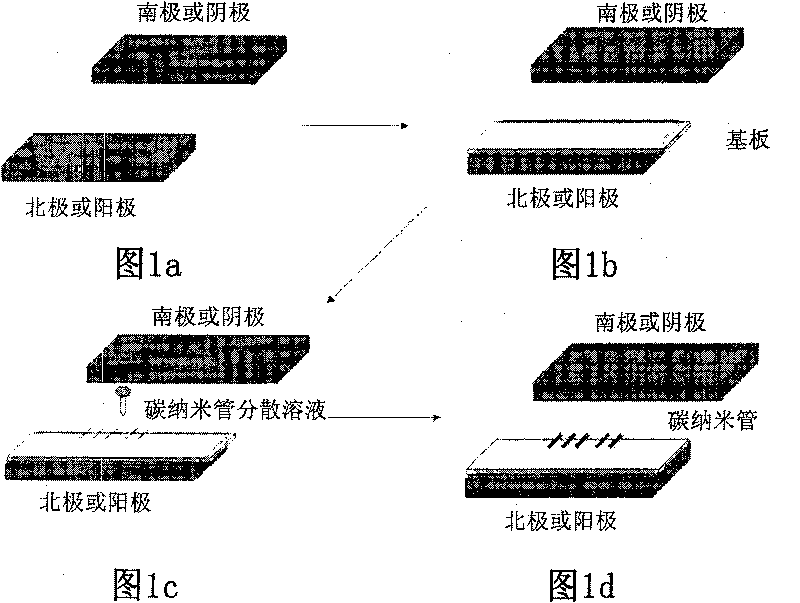

[0058] Example 3: Dispersing Magnetic Particles-Carbon Nanotubes on a Substrate

[0059] 5 mg of magnetic particle-carbon nanotubes prepared in Example 2 were dispersed in 50 ml of dimethylformamide (DMF), and then 10 ml of the dispersion was diluted in 40 ml of pure dimethylformamide (DMF).

[0060] Meanwhile, indium tin oxide (ITO) glass was fixed to a magnet with a magnetic field strength of 1000 Gauss, and placed in an oven at 120°C. When the temperature of the indium tin oxide (ITO) glass was raised to 120°C, 1 μl of the above solution of carbon nanotubes combined with magnetic particles diluted in dimethylformamide was dropped on the indium tin oxide (ITO) glass in the oven. ) on the glass and kept at 120° C. for 10 minutes to evaporate the dimethylformamide (DMF).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com