6 freedom degree micromotion operating platform

A workbench and degree-of-freedom technology, used in microlithography exposure equipment, photolithography process for patterned surfaces, photolithography process exposure devices, etc. Problems such as poor structural integrity and thick platform body achieve the effect of simple structure, low driving center of mass, and high displacement resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

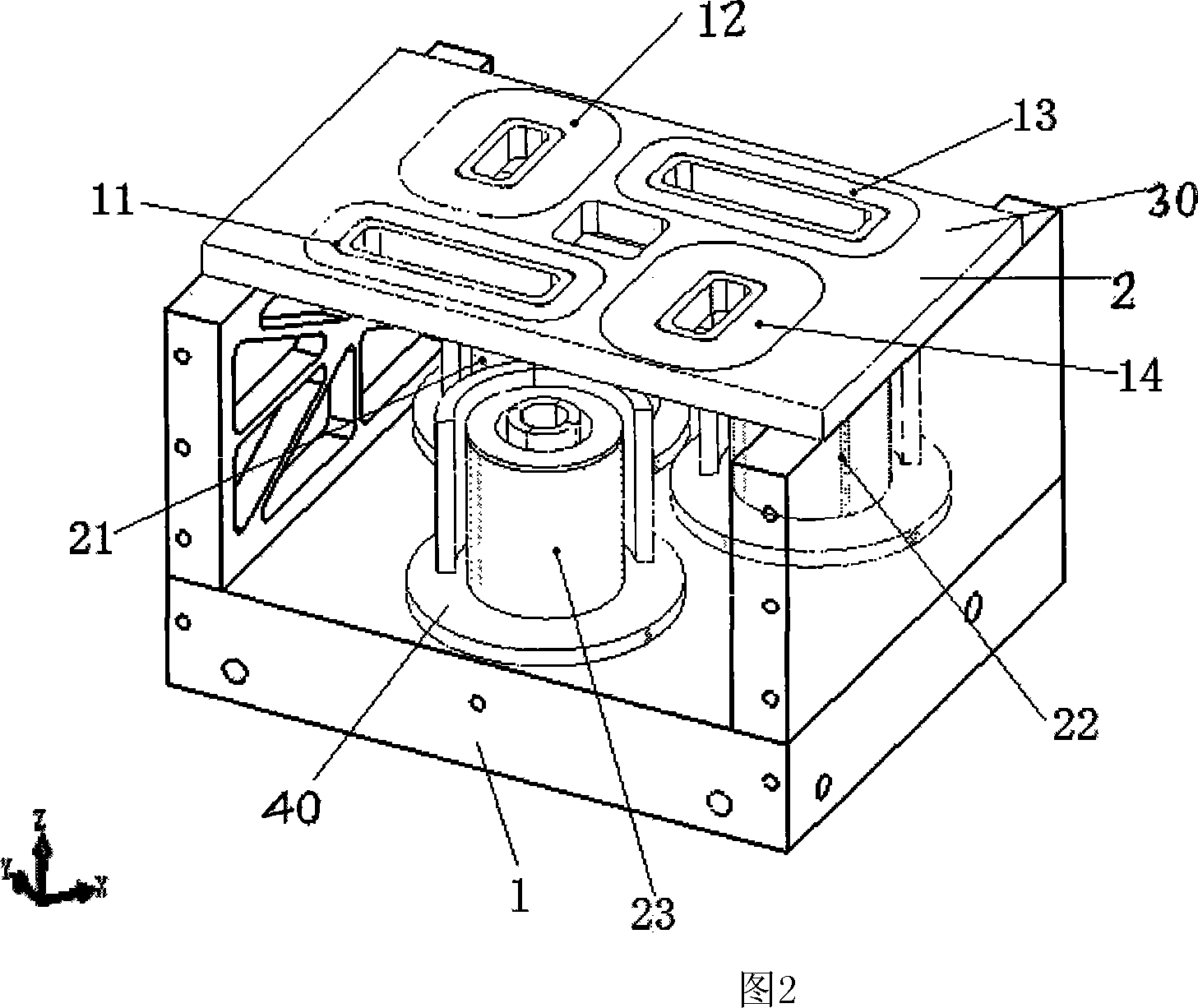

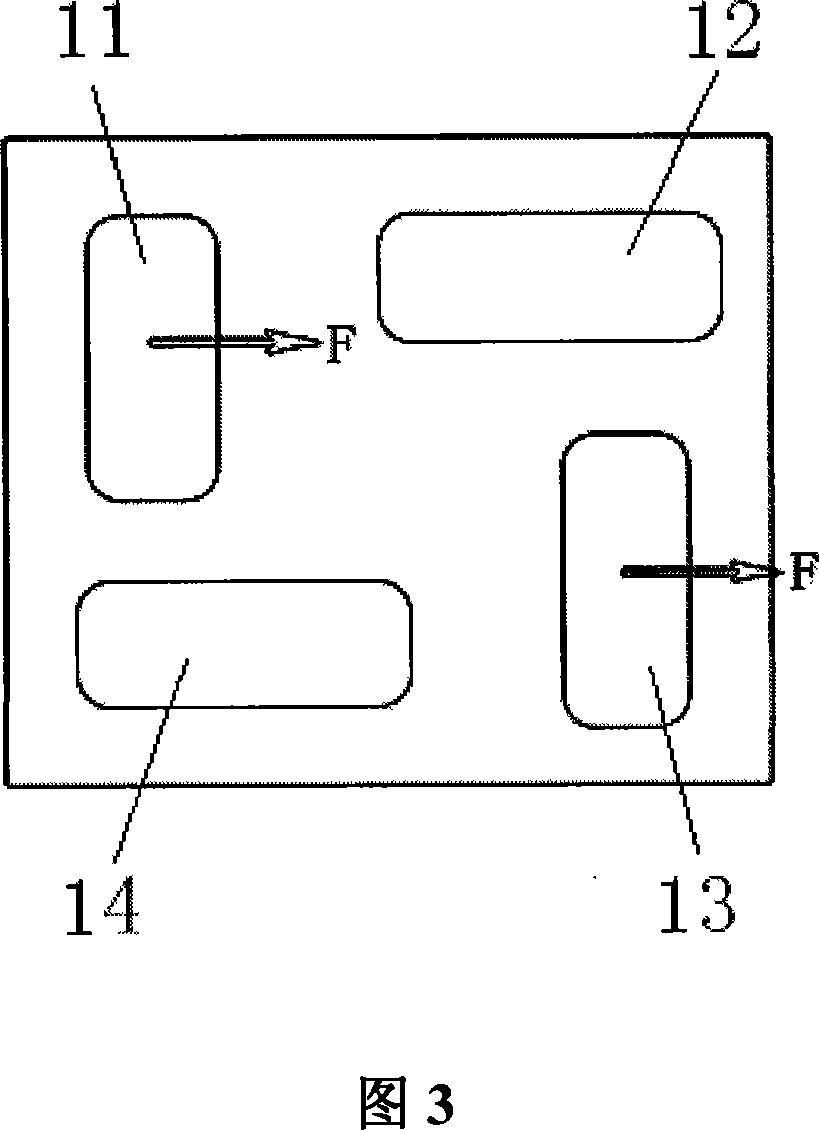

[0021] Fig. 1 is a three-dimensional structure diagram of a 6-DOF micro-motion worktable provided by the present invention. The micro-motion worktable includes a micro-motion table base 1 , a micro-motion table stator 2 , and a micro-motion table mover 3 . The micro-motion table has 3 groups of electromagnetic drive units arranged in the horizontal plane, wherein the drive axes of the 2 groups of drive units are parallel but not coincident, the drive axes of the 3rd group of drive units are orthogonal to the first 2 groups, and the drive axes of the 3 groups The electromagnetic drive unit arranged in the horizontal plane realizes the X, Y, θ of the micro-movement table in the horizontal plane z 3 degrees of freedom of movement; each group contains at least one electromagnetic force drive unit, each electromagnetic force drive unit is composed of a planar permanent magnet and a coil polarized in the vertical direction, and the planar permanent magnet is arranged on the effecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com