Dew point plate type indirect evaporation cooler

An evaporative cooler and plate type technology, applied in the field of evaporative coolers and plate type indirect evaporative coolers, can solve the problems of small temperature drop and limited use range, and achieve the effect of uniform water distribution and effective promotion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

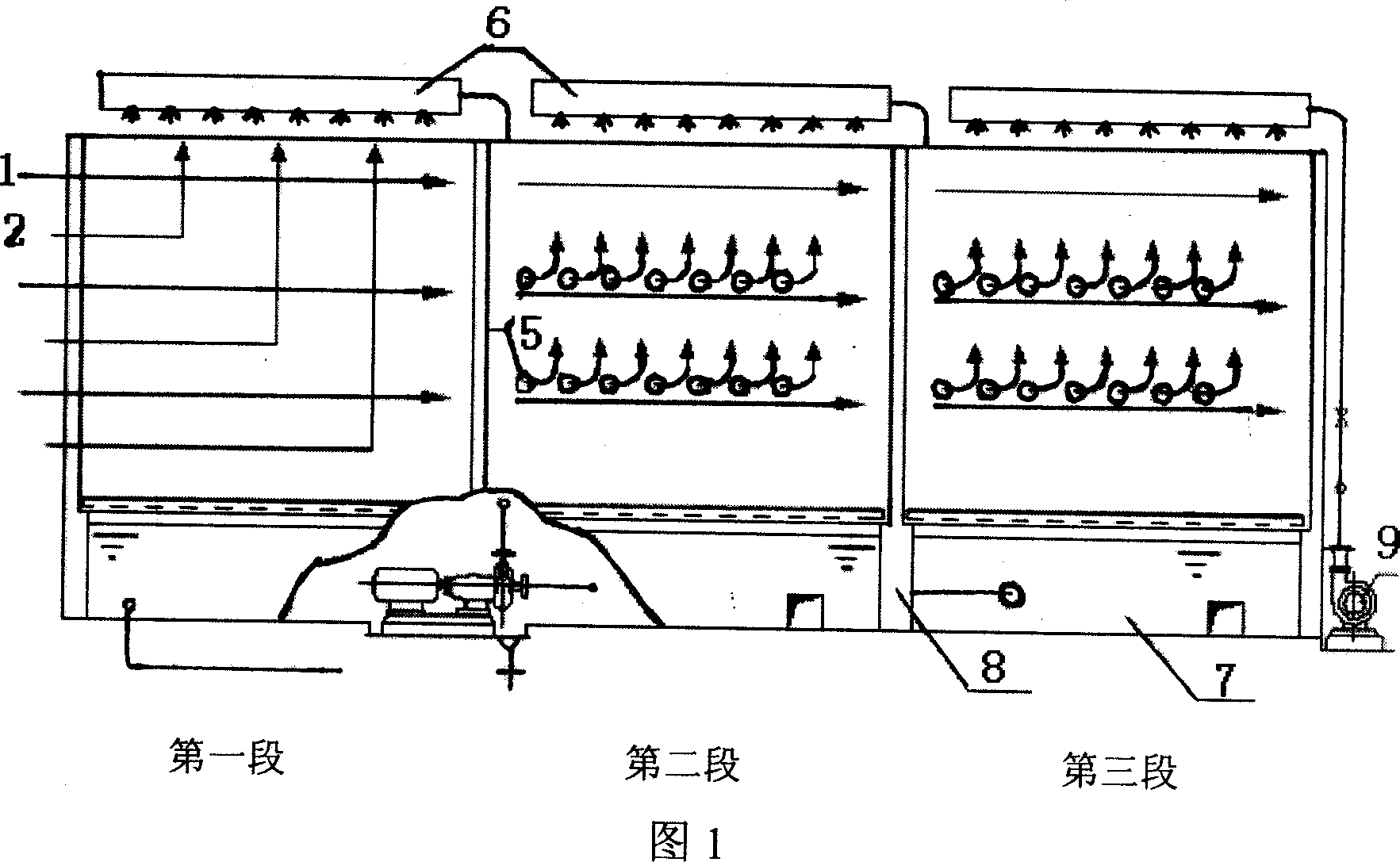

[0026] Figure 1 shows an embodiment of a dew point plate type indirect evaporative cooler provided by the present invention. Including the plate cooler core and water supply device, the plate cooler core is composed of a pre-cooling section and two cooling sections, the cooling principle of the pre-cooling section is the same as the indirect evaporative cooling principle of the prior art, but the secondary air channel The structure is different, and the two cooling sections have the same structure, which is a dew point indirect evaporative cooling section with through holes.

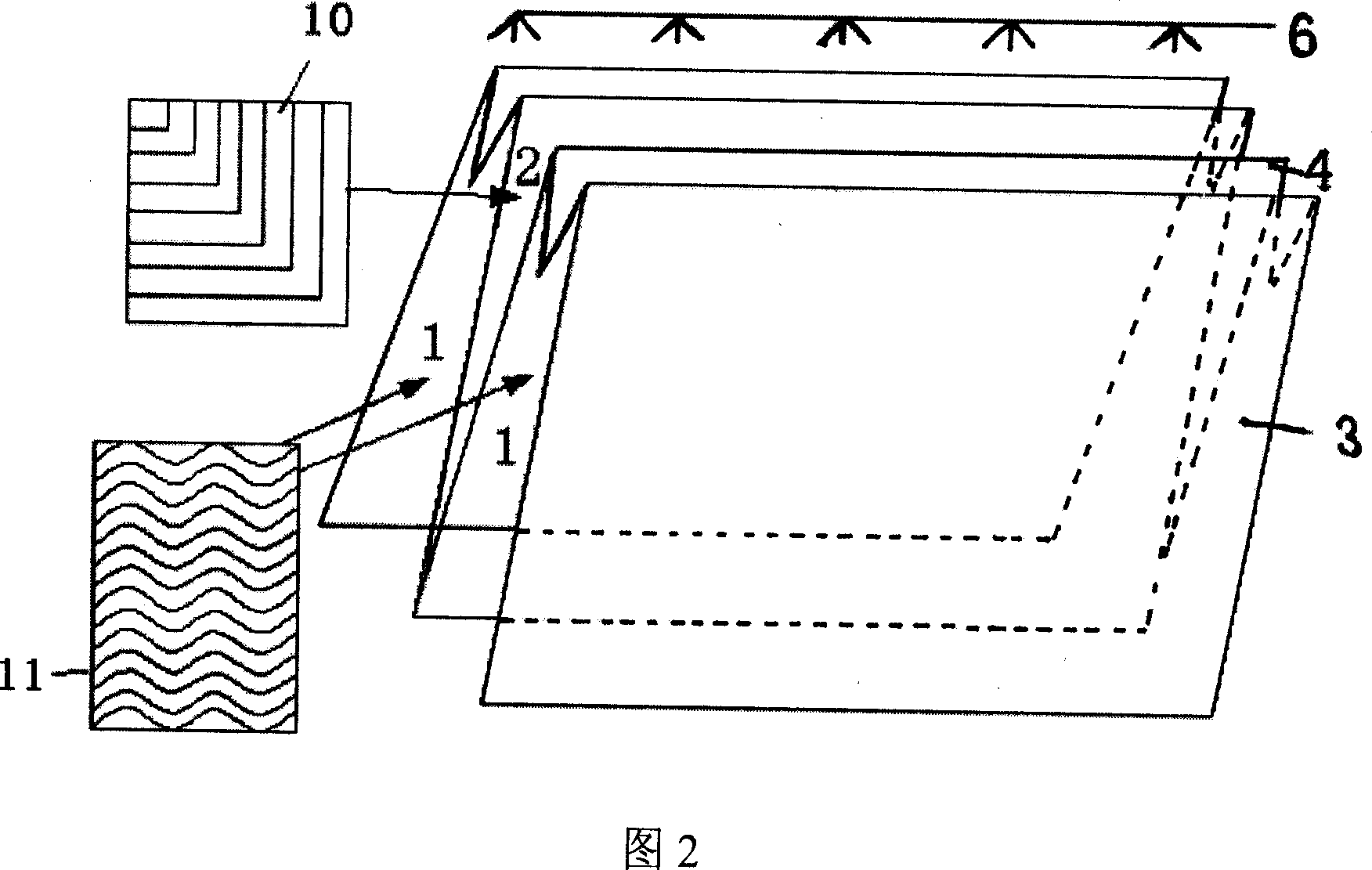

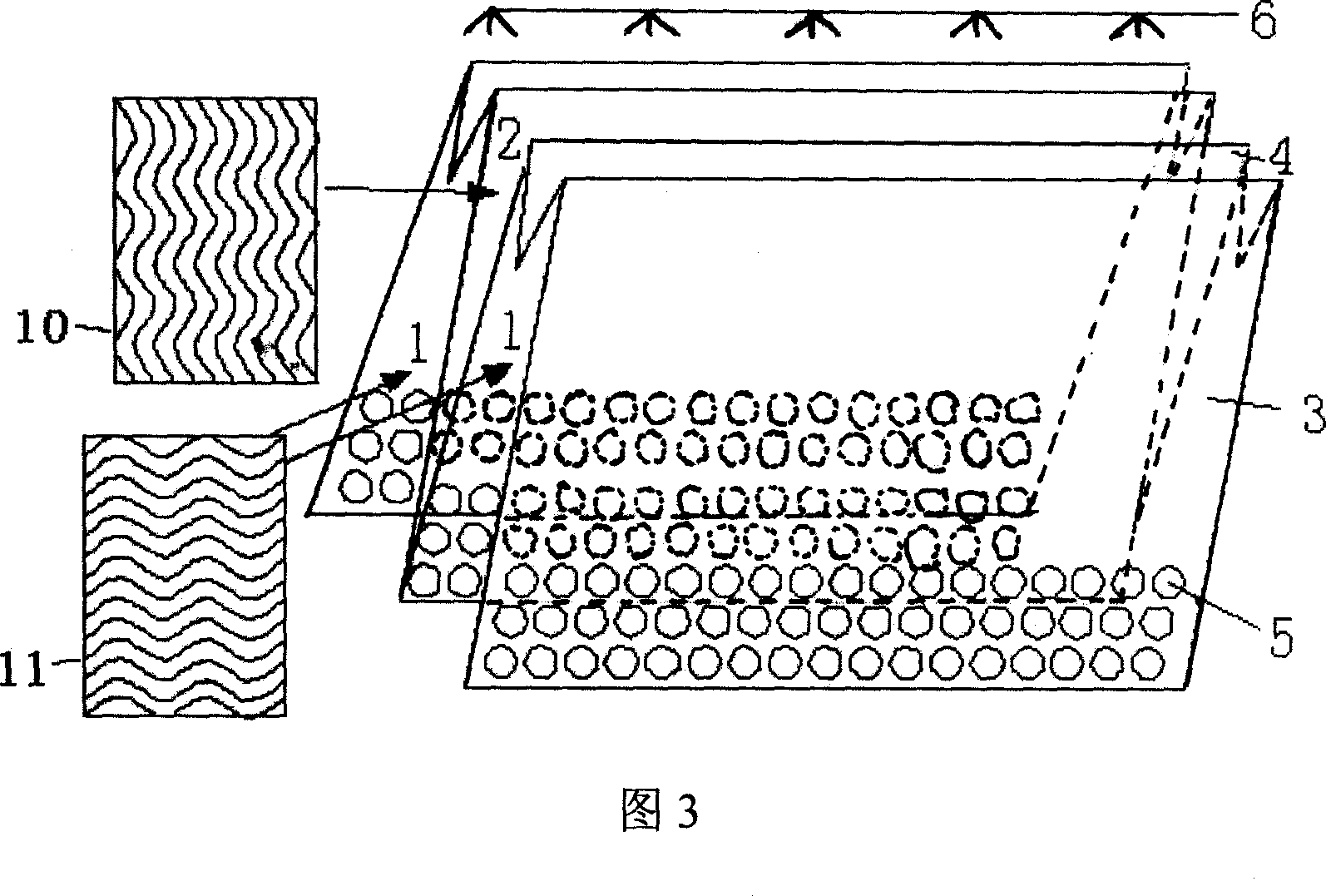

[0027] In the pre-cooling section and the cooling section, the folded interlayer 3 made of fiber paper and the interlayer curved flow channel 10 or corrugated flow channel 11 together form an air channel. One side of the fiber paper is a rough surface, and the other sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com