Combined sealing gas ring

A combined, gas ring technology, applied in the direction of piston rings, engine components, machines/engines, etc., can solve the problems of grinding off welding materials, destroying design functions, and inability to effectively block piston ring air leakage, etc., to reduce deformation, Effects that do not affect appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

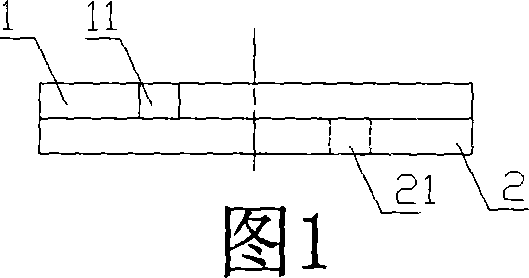

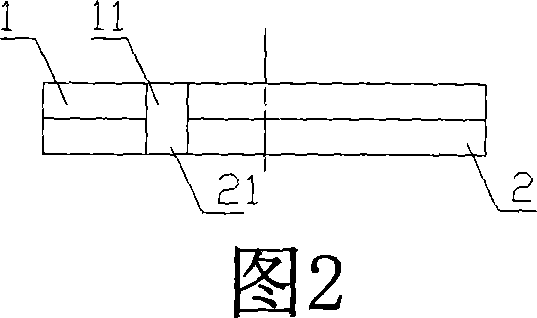

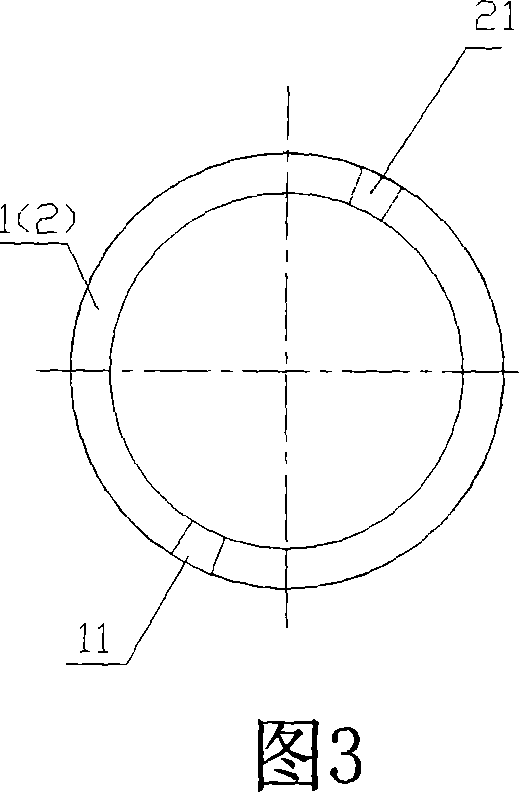

[0038] The specific scheme adopted by the present invention is shown in Fig. 11, Fig. 12, and Fig. 13. The upper composition ring 1 and the lower composition ring 2 are assembled in the same piston ring groove through an interlocking positioning device and a sealing device. First, as shown in Figure 5 and Figure 6, there is a cutout 12 at the inner end of the inner surface of the inner circle of the upper ring 1, the center of the cutout 12 and the line connecting the center of the upper ring 1 and the upper ring 1 The edge of the opening 11 and the line connecting the center of the upper ring 1 form an angle α, where α is 8°-25°, which can be determined according to the size of the piston ring with different cylinder diameters; the inner end of the inner surface of the inner circle of the lower ring 2 There is also a slot 22 in the position, the central position of the slot 22 and the line connecting the center of the lower ring 2 and the line connecting the edge of the openin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com