Composite flour additive agent and preparation method thereof

A compound flour and additive technology, which is applied in dough processing, baking, food science, etc., can solve the problems of insufficient fermentation stamina, inability to have a good volume and height, and cancer-causing problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Example 1: Three raw materials of sodium vitamin C phosphate, phosphatase and cornstarch that meet food grade requirements are sieved at 80 meshes, and 800 kg of sodium vitamin C phosphate and 100 kg of phosphatase that have been sieved are weighed, and corn Starch 100kg. The three raw materials are fully mixed and stirred until the three raw materials are mixed evenly.

Embodiment 2

[0016] Embodiment 2: Three kinds of raw materials of vitamin C phosphate sodium, phosphatase and cornstarch that meet food grade requirements are sieved at 80 meshes, and 400 kg of vitamin C phosphate sodium that has been sieved, 50 kg of phosphatase, and corn starch are weighed. Starch 500kg. The three raw materials are fully mixed and stirred until the three raw materials are mixed evenly.

Embodiment 3

[0017] Embodiment 3: Three kinds of raw materials of vitamin C phosphate sodium, phosphatase and cornstarch that meet food grade requirements are sieved with 80 meshes, and 100 kg of vitamin C phosphate sodium that has been sieved, 10 kg of phosphatase, and corn starch are weighed. Starch 900kg. The three raw materials are fully mixed and stirred until the three raw materials are mixed evenly.

[0018] Effect:

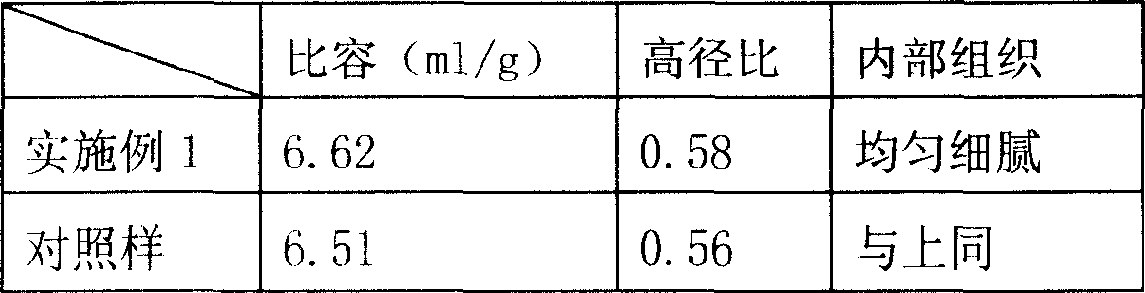

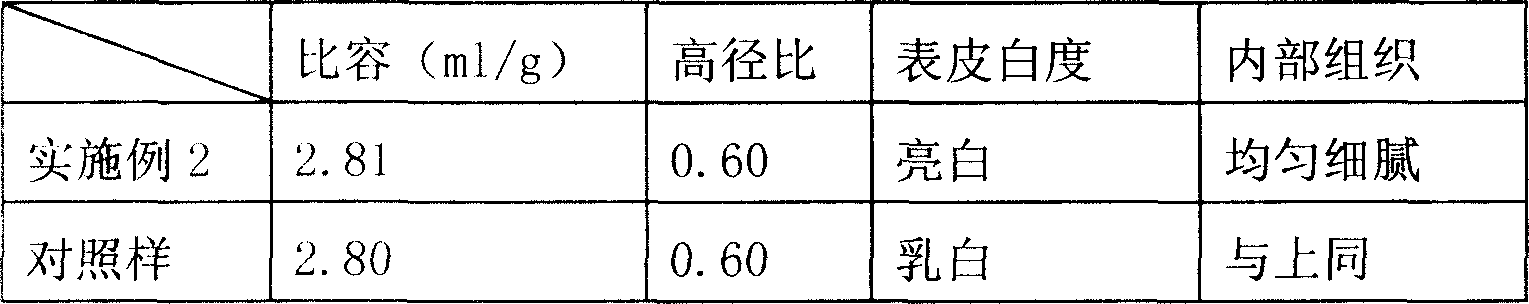

[0019] Application in special bread flour: add 0.03g of the product obtained in Example 1 to 1kg of flour and mix evenly, and compare it with making bread after adding 0.03g of potassium bromate in 1kg of flour and mixing evenly. The production process of bread is as follows: ingredients→stirring→first fermentation→cutting→rounding→second fermentation→shaping→proofing→baking→cooling→finished product. Accurately weigh 1kg of mixed flour, 10g of yeast, 90g of oil, 7g of salt, 200g of sugar, 10g of milk powder, and 550g of water, and put in the raw materials in order fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com