Vibration ceramic resonance of independent flake thickness-changing and its production

A ceramic resonator, shear vibration technology, applied in the direction of electrical components, impedance networks, etc., can solve the problems of high manufacturing cost, poor contact, low efficiency, etc., to avoid instability and thermal shock caused by instability, improve Reliability and cost reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

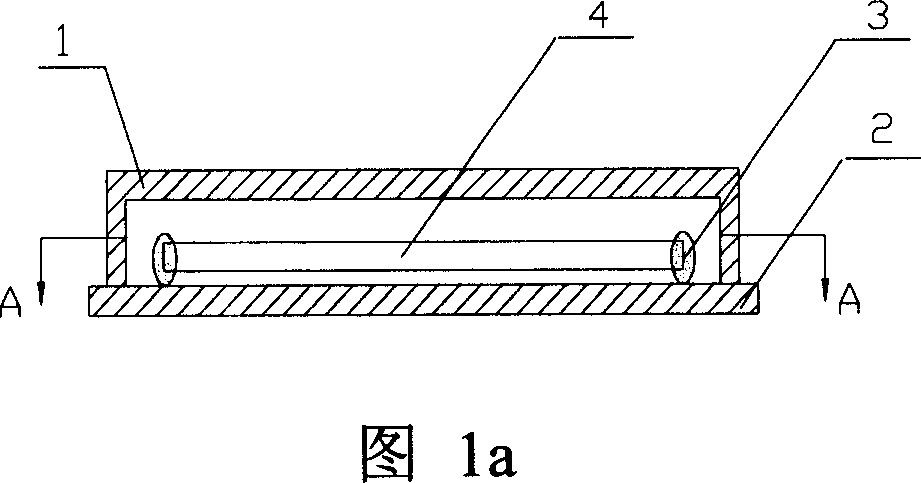

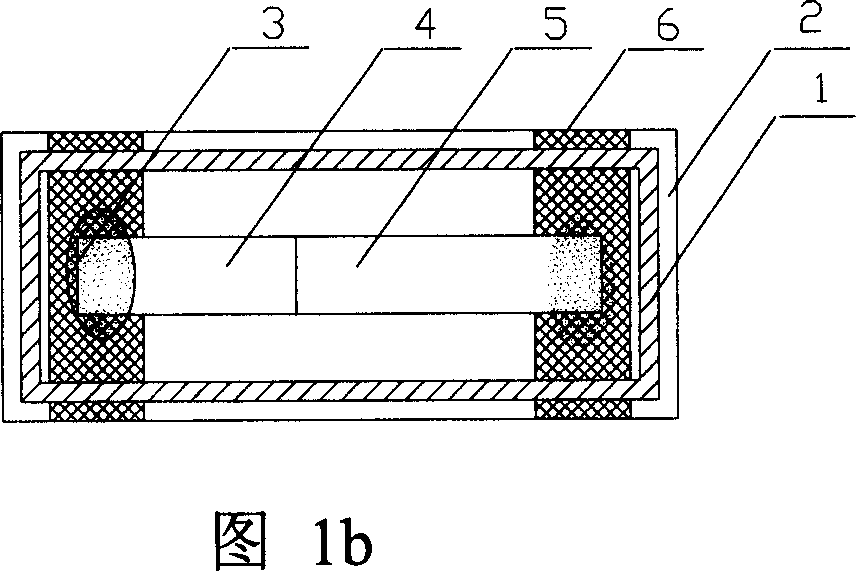

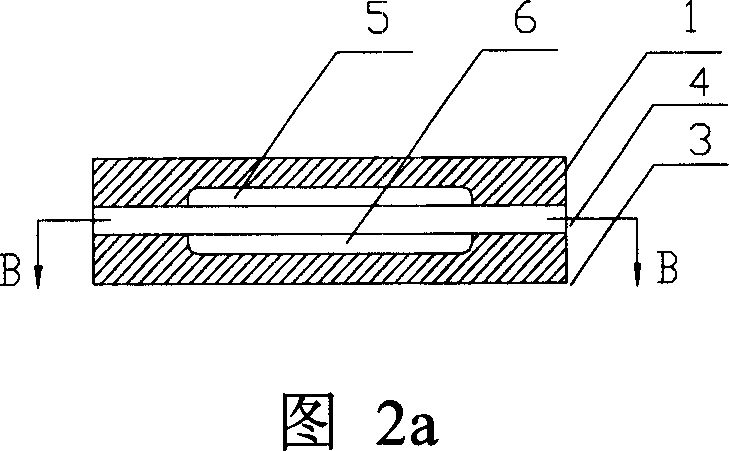

[0029] Please refer to Figures 2 to 6, it can be seen from the figures that a monolithic chip thickness shear vibration ceramic resonator includes a cover plate 1, a middle splint 2, a bottom plate 3, a piezoelectric ceramic vibrator 4, and multiple cover plates The pits 5 , the bottom plate pits 6 , and the number of the cover plate 1 and the bottom plate 3 correspond to the number of holes 7 in the intermediate splint, the piezoelectric ceramic vibrator electrodes 8 and the external electrodes 9 . The cover plate 1, the middle splint 2, and the bottom plate 3 are bonded together, and the cover plate pits 5, the bottom plate pits 6 and the middle splint holes 7 form a plurality of cavities of the resonator, each of which is 24 in the figure indivual. Among them, the holes in the middle splint 7 or the adjacent holes are connected in the length direction by through holes or channels smaller than the width of the holes. The piezoelectric ceramic vibrator 4 is located in the hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com